Array micro-joist unit deflection angle measuring systems

A measurement system and micro-beam technology, which is applied in the direction of measurement devices, optical components, optics, etc., can solve the problems of bulky and inability to measure the deflection angle of array-type micro-beams, and achieve the effect of improving detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

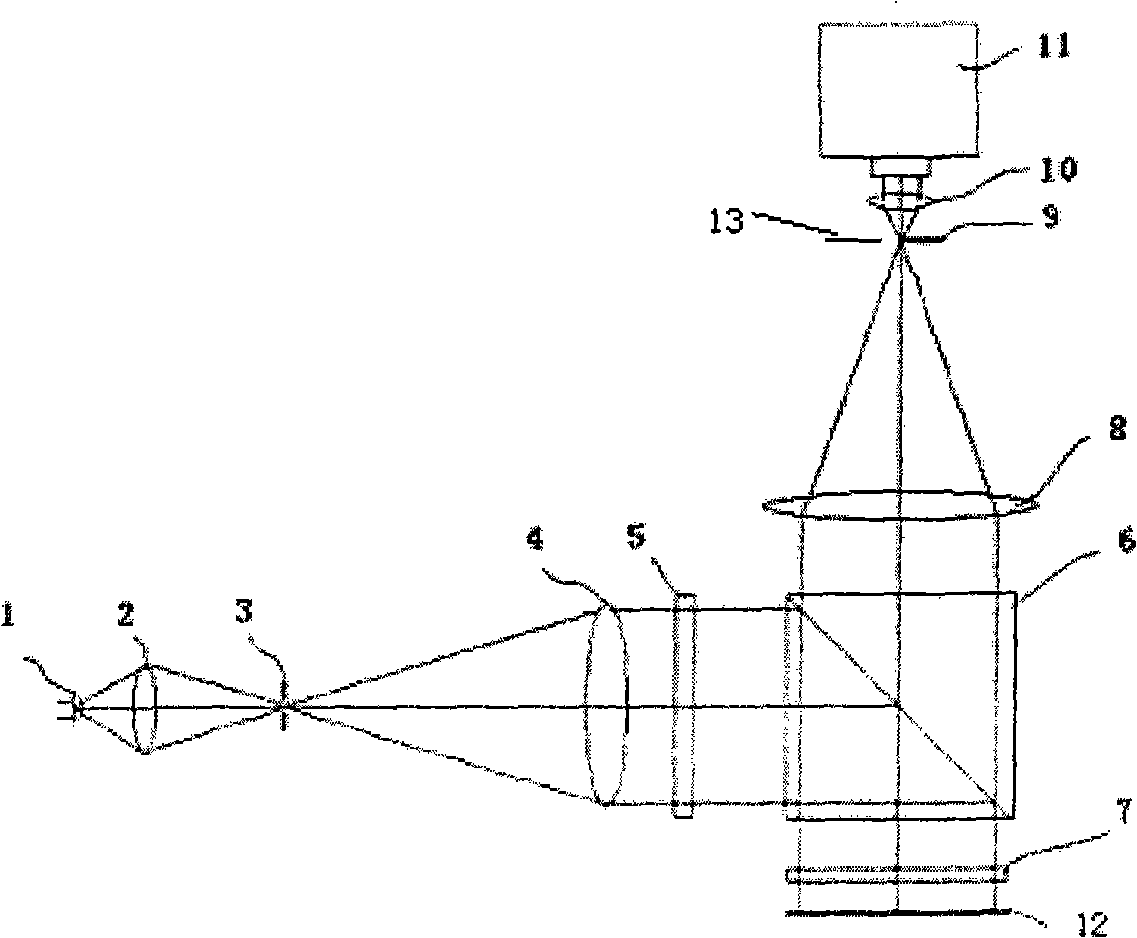

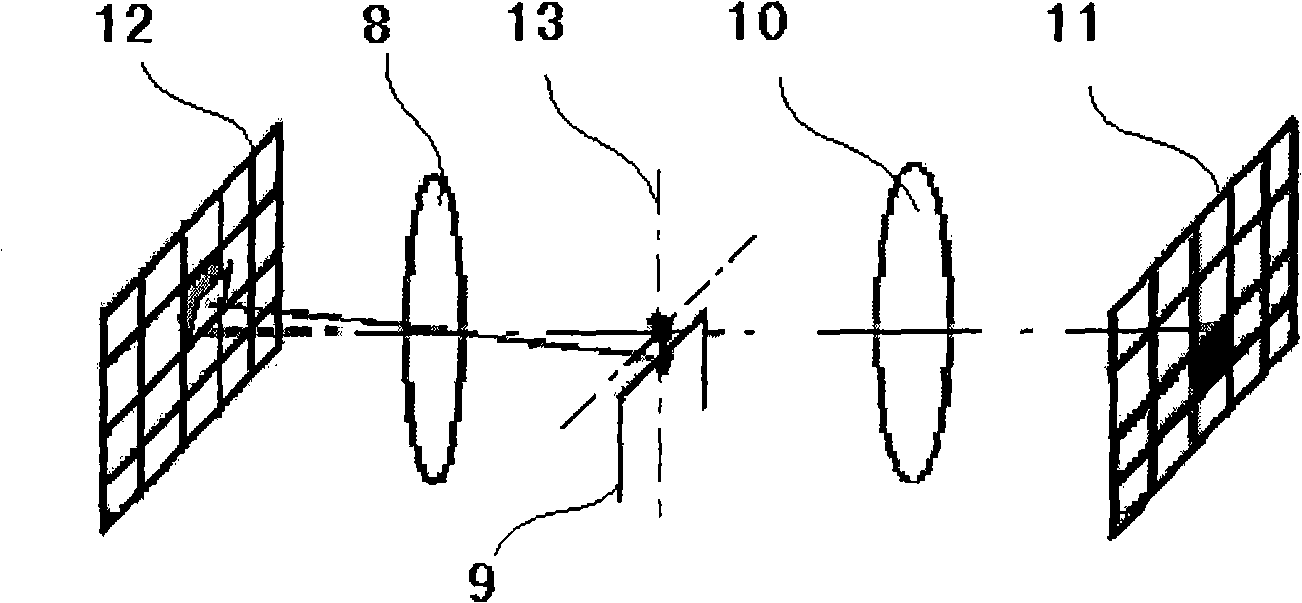

[0015] Such as figure 1 As shown, the device of the embodiment of the present invention consists of an illumination source 1, a condenser lens 2, a filter pinhole 3, a collimation system 4, a polarizer 5, a polarizing beam splitter 6, a 1 / 4 wave plate 7, a Fourier transform system 8, and a filter knife edge 9. A Fourier inverse transform system 10, a CCD camera 11, and an array microbeam 12 are composed.

[0016] The monochromatic light source in the range of 400nm-600nm is used as the lighting source 1, and the lighting source commonly used in engineering technologies such as lasers and light-emitting diodes can be selected. The light emitted by the lighting source 1 is combined by the condenser lens 2 and the filter pinhole 3 to form a lens-needle The hole space filter forms a point light source, and this point light source passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com