Integrated type cooling and temperature preservation battery system and control method thereof

A battery system and integrated technology, applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems of low heat dissipation efficiency, poor heat dissipation effect, weak control, etc., to reduce energy consumption and improve battery life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

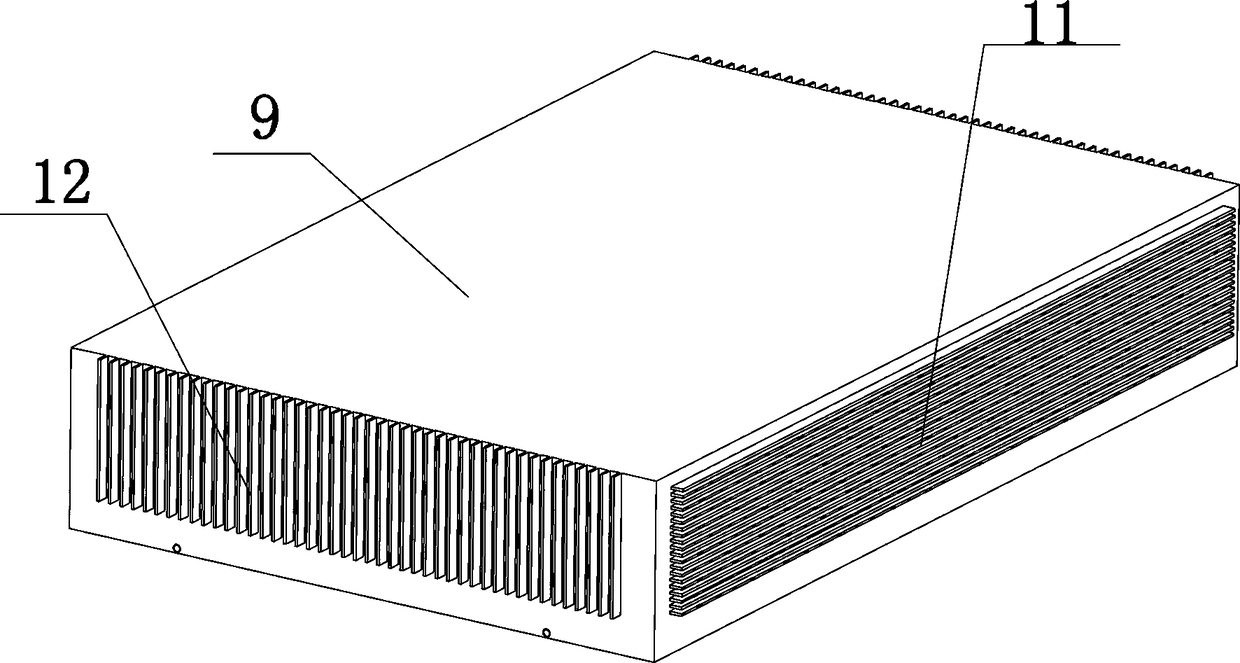

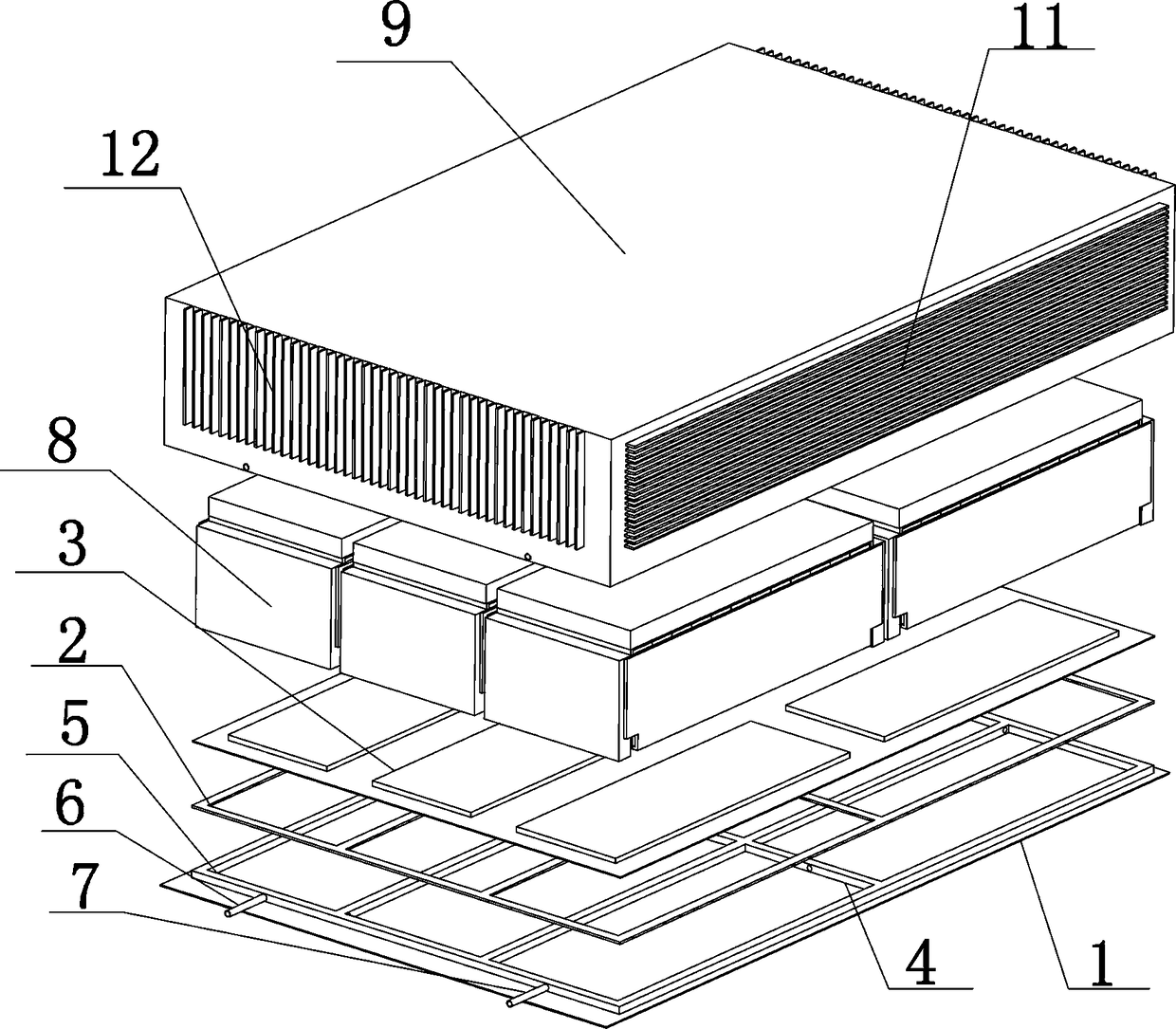

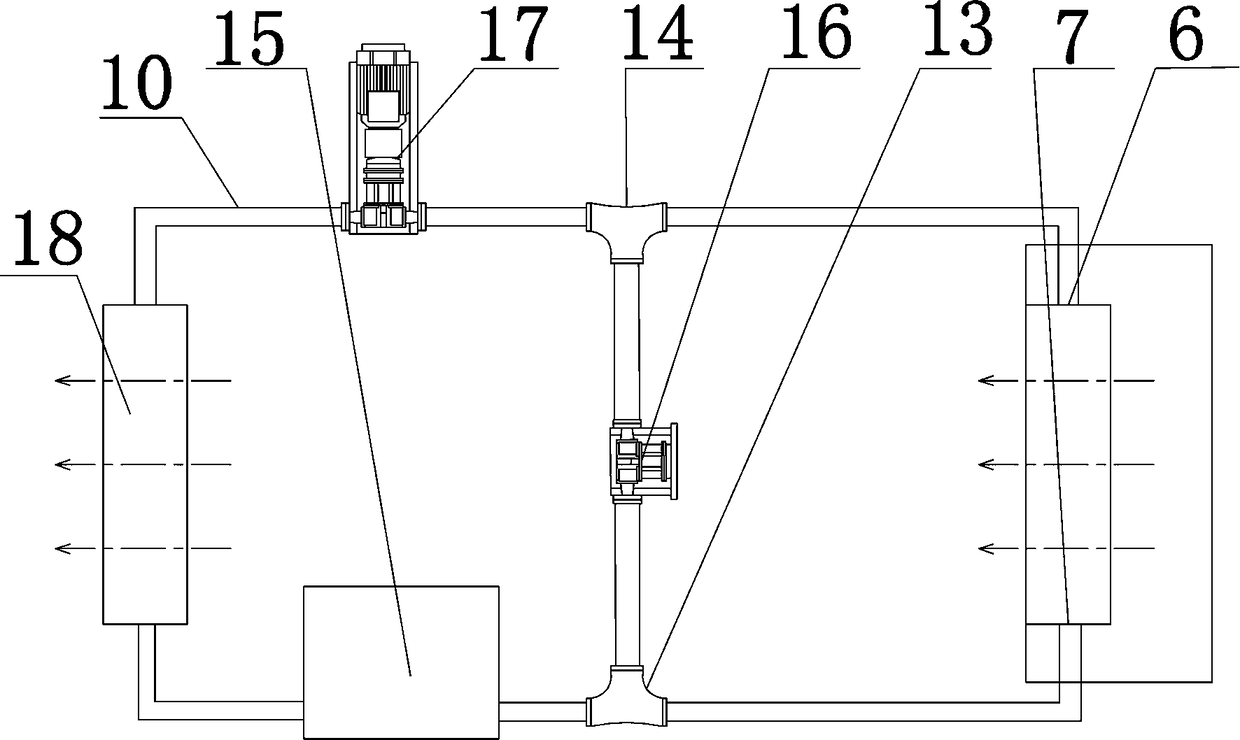

[0032] The invention relates to an integrated cooling and heat preservation battery system, which includes a battery box body, the battery box body includes a lower box body, and the lower box body includes a lower box cover 1 and a heat insulation layer 2 arranged sequentially from bottom to top and the heat conduction plate 3, the lower box cover 1 is provided with a groove body 4, and the groove body 4 cooperates with the heat insulation layer 2 to form a closed flow channel 5, the outlet 6 of the flow channel 5 and the outlet 6 of the flow channel 5 The inlets 7 are respectively arranged on the sides of the lower box; the heat conducting plate 3 is provided with a battery module block 8, and an upper box 9 is arranged on the lower box outside the battery module block 8; The module block 8 is equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com