Uniform-fertilizing automatic earthing equipment

An automatic and soil-covering technology, applied in shovels, ploughs, agricultural machinery and implements, etc., can solve problems such as troublesome use and resource consumption, and achieve good fertilization effect, prevention of outward loss, and good practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

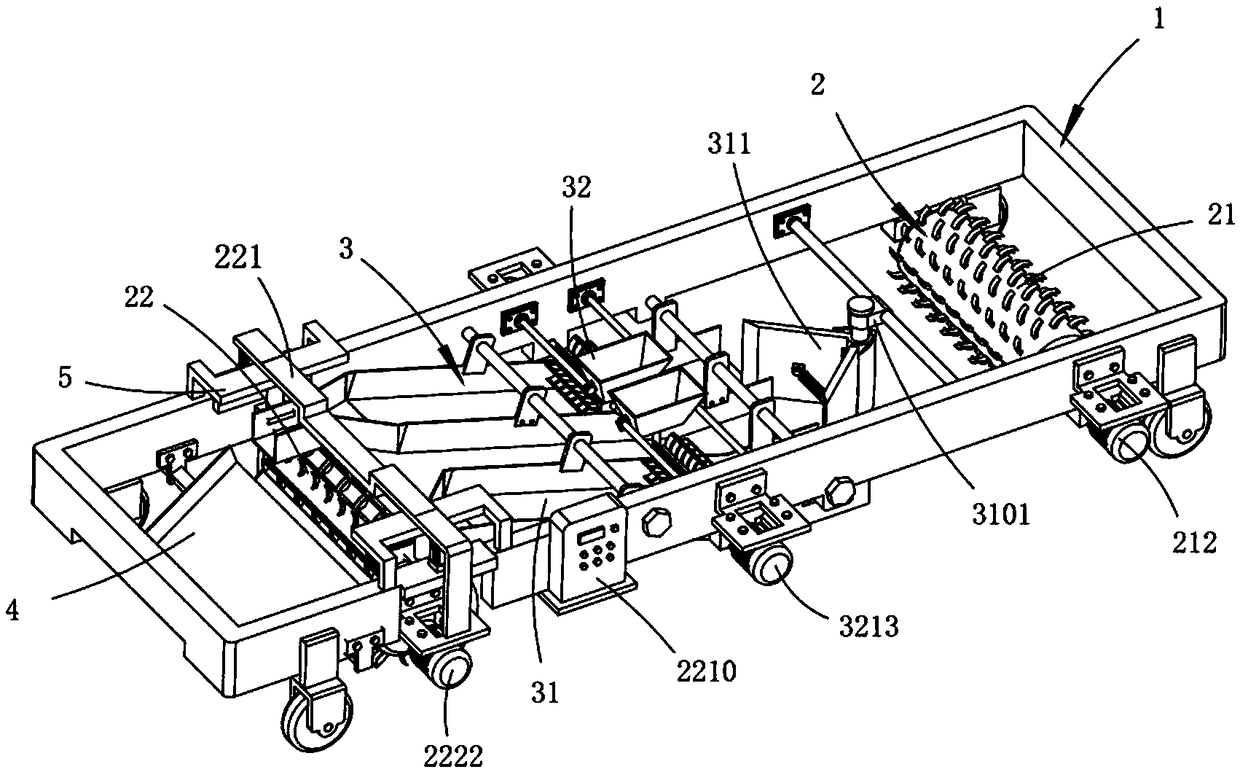

[0064] Such as figure 1 , figure 2 and image 3 As shown, a kind of automatic soil covering equipment for uniform fertilization, including walking carrier 1, also includes:

[0065] The soil loosening part 2, the soil loosening part 2 is installed on the walking carrier 1, which includes a shallow soil loosening device 21 installed at the front part of the walking carrier 1, a deep layer loosening device 21 installed at the rear part of the walking carrier 1 Soil loosening device 22, described shallow soil loosening device 21 carries out soil loosening work to the upper surface soil of land, and described deep layer loose soil device 22 is used for carrying out deep soil loosening operation to the land that finishes upper surface soil loosening operation , and move the loose deep soil backwards;

[0066] Soil transfer part 3, described soil transfer part 3 is installed on the described walking carrier 1, and it is positioned between described shallow layer loosening device...

Embodiment approach

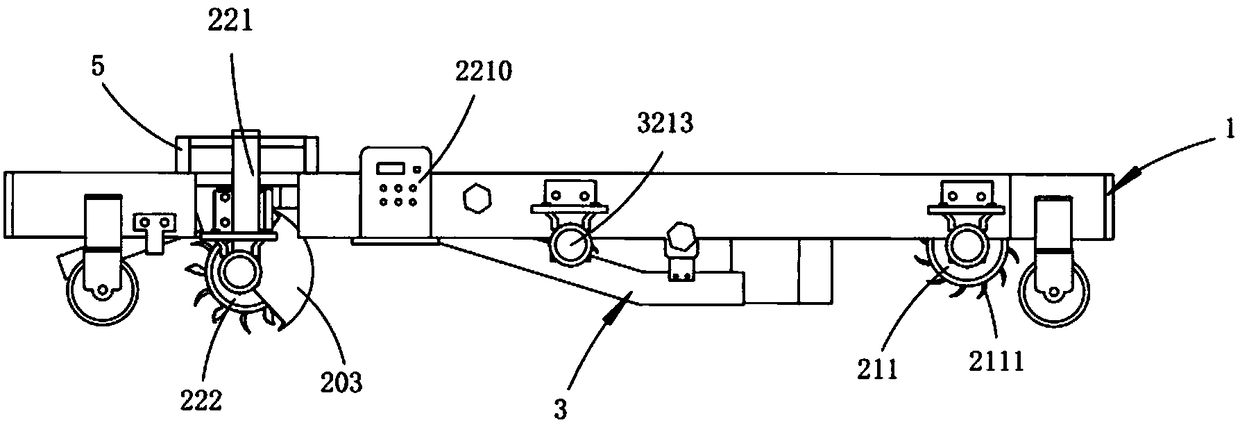

[0068] As a preferred embodiment, the shallow layer loosening device 21 includes

[0069] The first soil loosening part 211, the first soil loosening part 211 is horizontally rotated and installed on the walking carrier 1, and a plurality of first soil loosening rake teeth 2111 are arranged around the outer peripheral surface equidistantly along the axial direction;

[0070] The first power part 212, the first power part 212 is fixedly arranged on the walking carrier 1, which drives the first soil loosening part 211 to perform soil loosening work;

[0071] Described deep layer loosening device 22 comprises

[0072] Lifting mechanism 221, the lifting mechanism 221 is installed on the walking carrier 1, which includes a lifting cylinder 2211 symmetrically arranged on the walking carrier 1 and a support frame 2212 that moves up and down under the synchronous drive of the lifting cylinder 2211;

[0073] The deep layer loosening mechanism 222, the deep layer loosening mechanism 22...

Embodiment 2

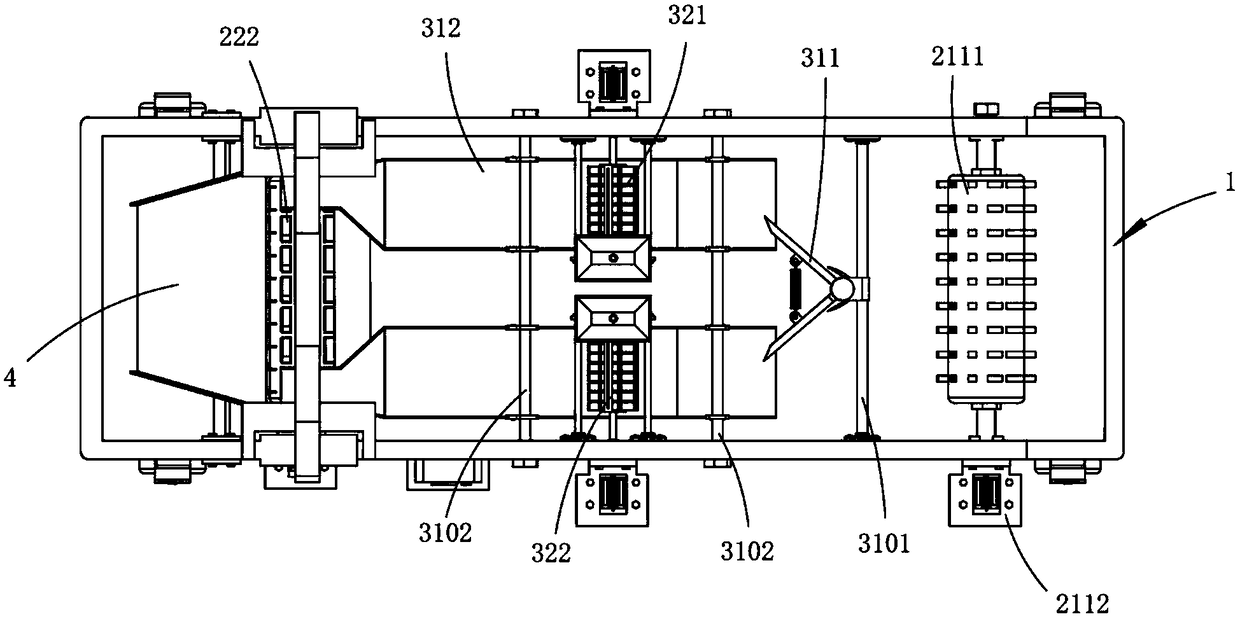

[0107] In order to evenly spread the upper surface soil transported by the soil transfer part on the deep soil, this example also provides an implementation, wherein the same or corresponding parts as in Example 1 use the corresponding drawings of Example 1 Marking, for the sake of brevity, only the differences from Embodiment 1 will be described below. The difference between this embodiment two and embodiment one is:

[0108] As a preferred embodiment, the rear of the deep soil loosening device 22 is also fixedly provided with a receiving plate 4 for receiving the upper surface soil output by the soil transfer part 3 backward;

[0109] It should be noted here that the output ends of the first conveying trough 3121 and the second conveying trough 3122 are gradually retracted to both sides to make room for the second soil loosening member 2221 to throw soil. The first conveying trough 3121 and the second conveying trough 3121 The upper surface soil output by the groove 3122 fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com