Reciprocating double-movable-knife bush harvester

A harvester and reciprocating technology, applied in the field of reciprocating double-acting blade shrub harvesters, can solve the problems of winding, high missed cutting rate, poor cutting quality, etc., and achieve the effects of high harvesting efficiency, stable performance and good stubble quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

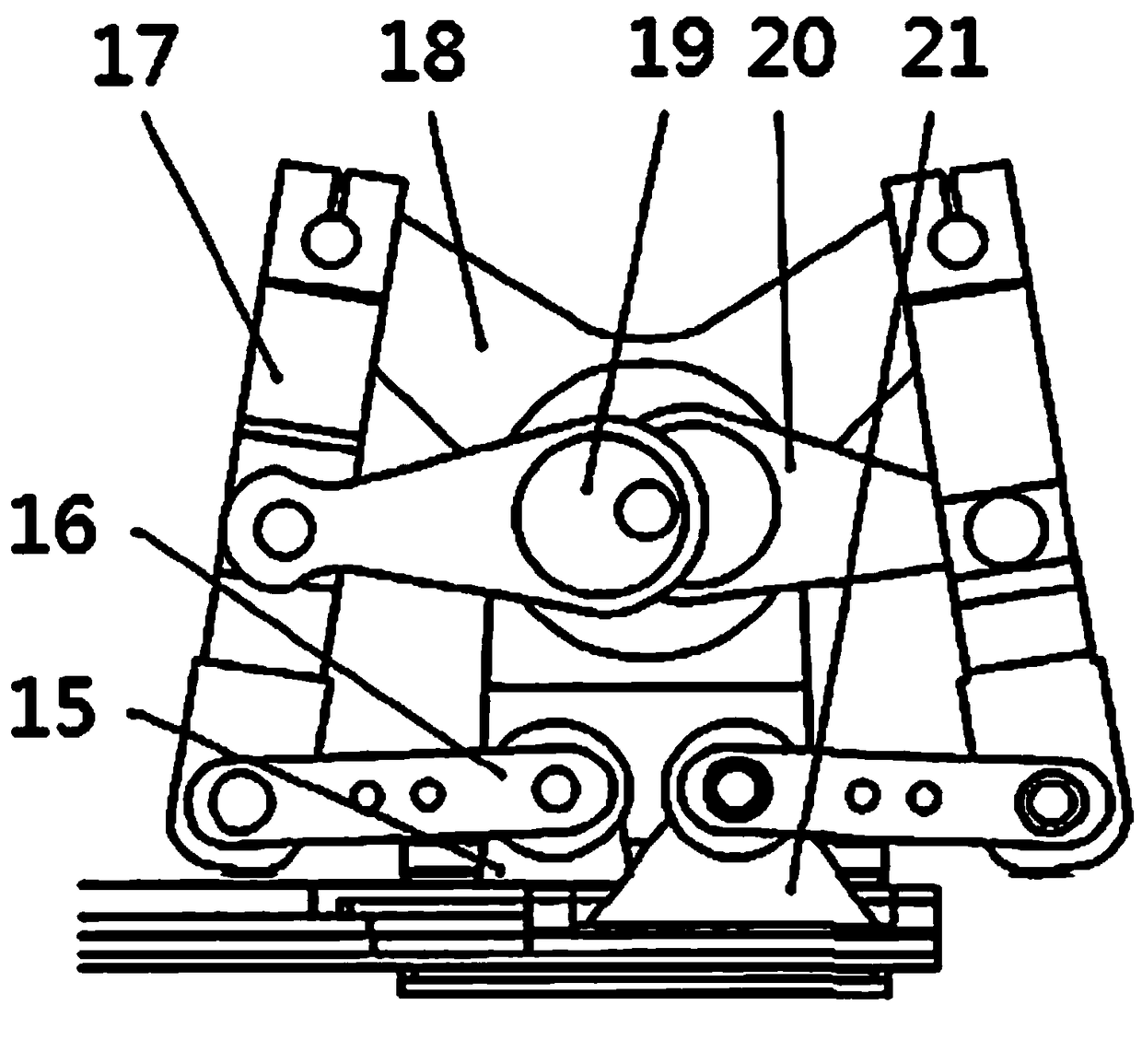

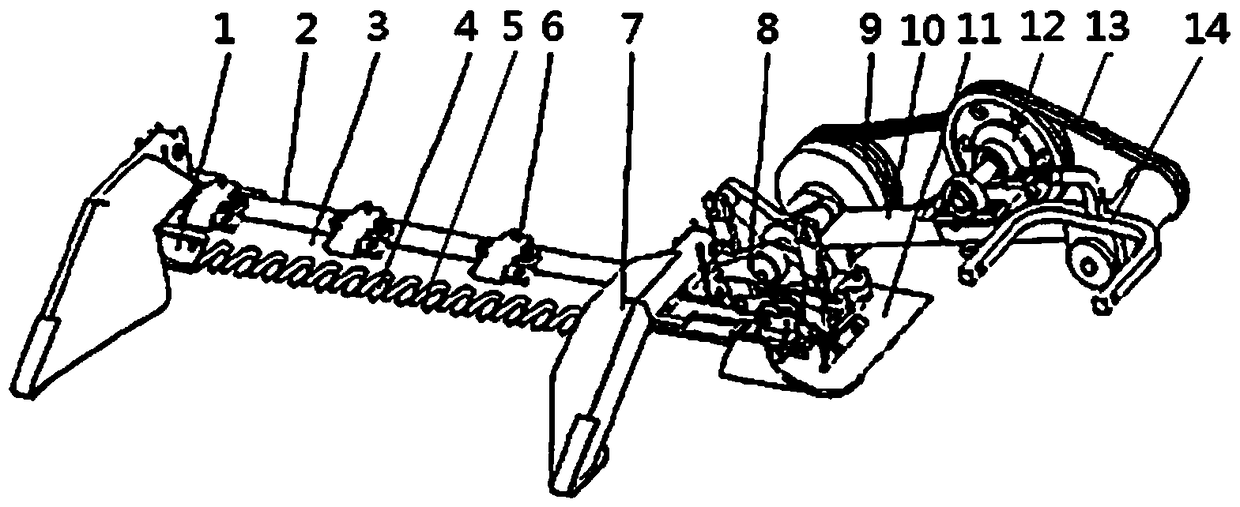

[0018] figure 1 The reciprocating double-knife shrub harvester is mainly composed of an outer sliding palm, a knife beam, an upper moving knife, a lower moving knife, a pressure blade (supporting blade), a floating branch mechanism, an eccentric shaft type double crank linkage mechanism, a flywheel, It is composed of frame, inner sliding palm, transmission mechanism, transmission pulley, transmission belt, suspension frame, etc.; the upper and lower moving knives are driven by two eccentric shafts and perform constant relative motion during work; the upper and lower moving knives The profile of the blade is a hexagonal trapezoid, so that the original height of the blade can be maintained after grinding. The material of the blade is T9 carbon tool steel, and the blade is quenched and tempered; The wide-type blade presser makes the gap between the blades stable and reliable; the drive pulley and the flywheel are respectively located at the two ends of the mandrel passing through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com