Formaldehyde catalyst contrast experiment self-balanced reaction equipment

A technology for comparative experiments and reaction equipment, which is applied in the fields of oxidation to prepare carbonyl compounds, organic chemistry, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

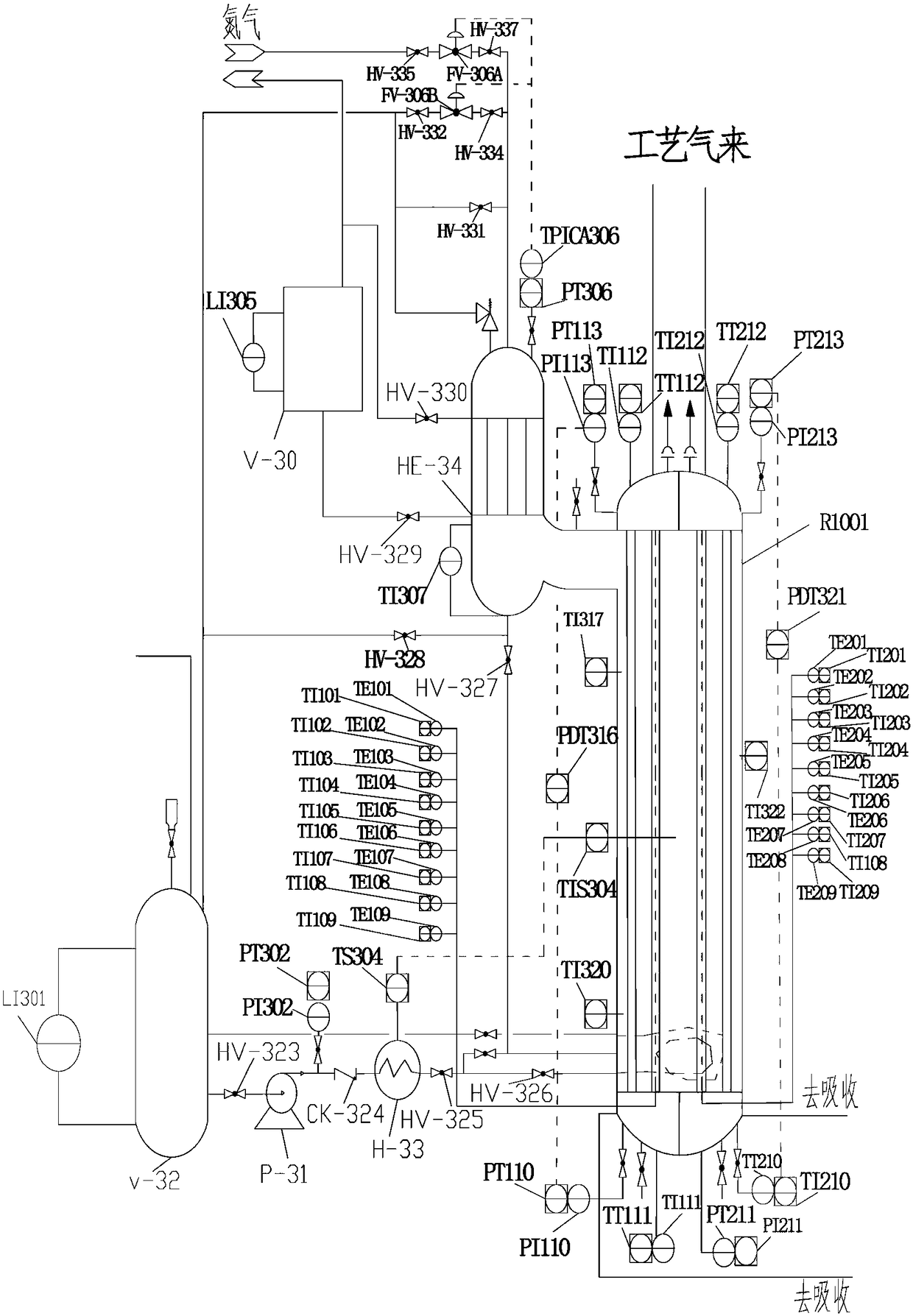

[0020] Such as figure 1 Shown: a formaldehyde catalyst comparative experiment self-balancing reaction equipment, including a reaction unit and a heat transfer oil unit; the reaction unit includes a shell-side reactor R1001, and the heat transfer oil unit includes a heat transfer oil tank V-32, a heat transfer oil pump P-31, Heat conduction oil electric heater H-33, heat conduction oil cooler HE-34; heat conduction oil tank V-32 is connected to the lower part of the shell side of reactor R1001 via heat conduction oil pump P-31, heat conduction oil electric heater H-33, and the reaction The upper part of the shell side of the device communicates with the heat transfer oil cooler HE-34, and the heat transfer oil cooler HE-34 communicates with the heat transfer oil tank V-32.

[0021] Preferably, a thermal oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com