Ammonia-doped power plant indirect air cooling system and control method thereof

A technology of an air cooling system and a control method, which is applied to the charging system, the turbine/propulsion fuel delivery system, and the fuel heating of the turbine/propulsion device, etc., can solve the problem that cannot meet the reasonable distribution of air cooling and liquid ammonia gasification cooling in ammonia-mixed power plants. and real-time regulation and other issues to achieve the effect of improving cooling effect, improving regulation effect, taking into account corrosion and freezing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

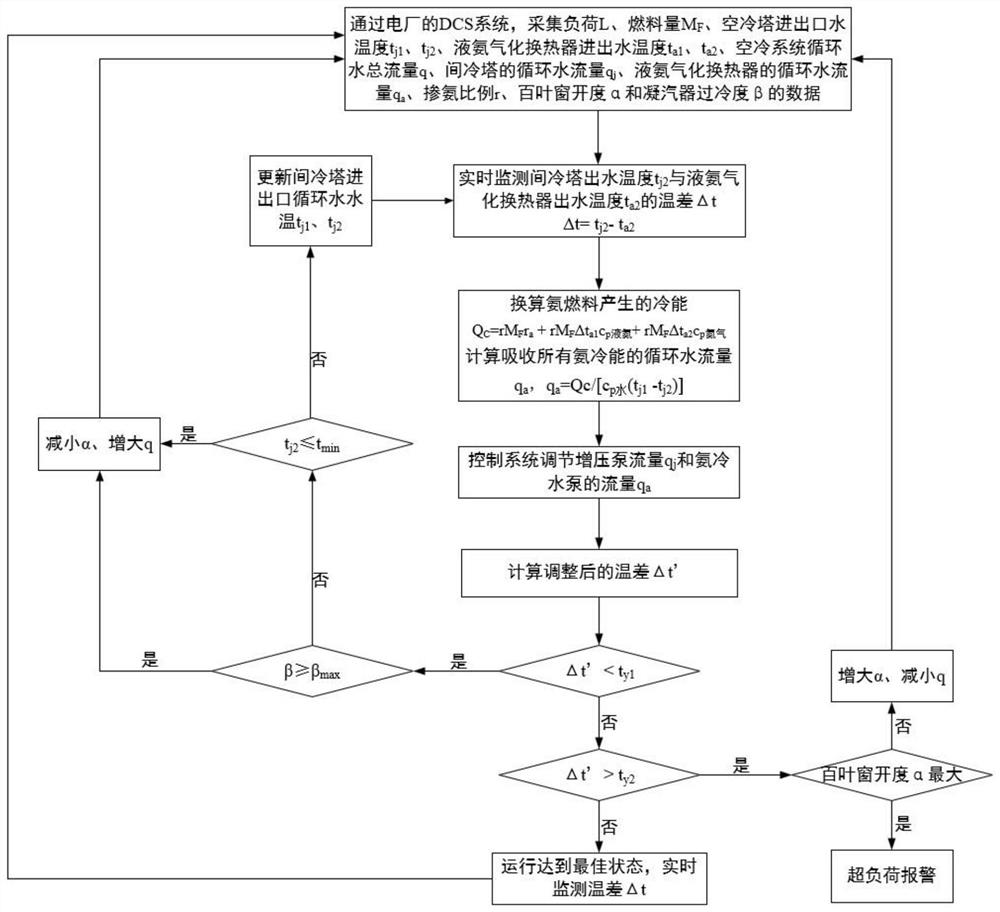

[0037] like figure 1 As shown, the present invention provides a kind of control method of the indirect air-cooling system of ammonia-doped power plant, and this method comprises the steps:

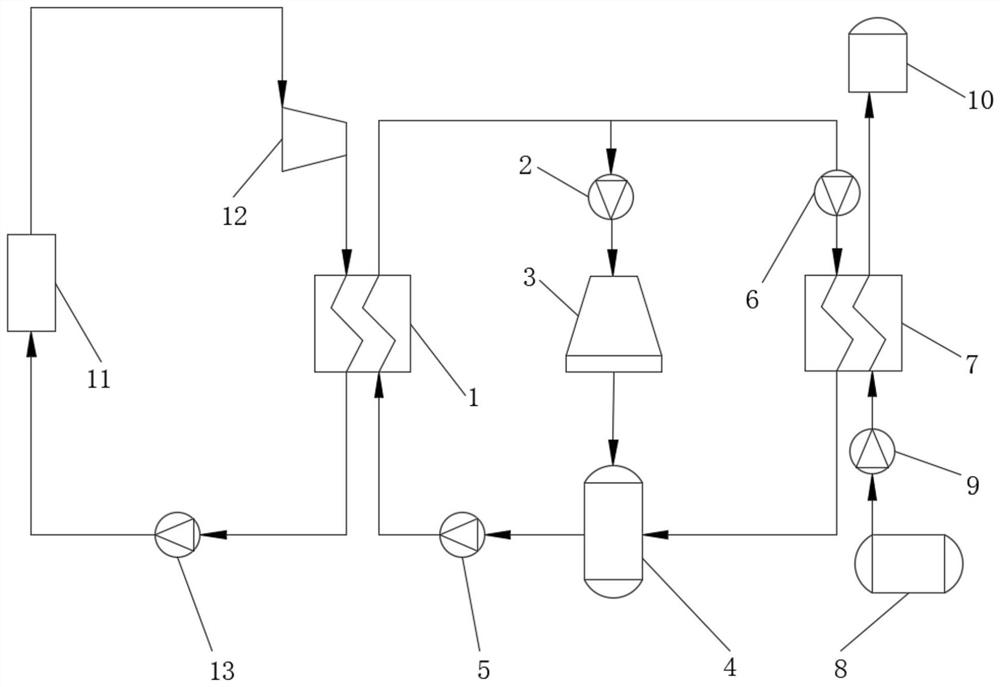

[0038] S1 uses the distributed control system (Distributed Control System, DCS) of the power plant to monitor the operating data of the power plant, including load L, fuel quantity MF , Inlet and outlet water temperature t of intercooling tower j1 and t j2 , Liquid ammonia gasification heat exchanger 7 Inlet and outlet water temperature t a1 and t a2 , the total flow of circulating water in the air cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com