Photovoltaic module sweeping robot system capable of automatically changing rows

A technology for cleaning robots and photovoltaic modules, applied in photovoltaic power generation, photovoltaic modules, cleaning methods using tools, etc., can solve the problems of low cleaning speed, small contact area of components, small size of small robots, etc., to ensure operation and accurate positioning. matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

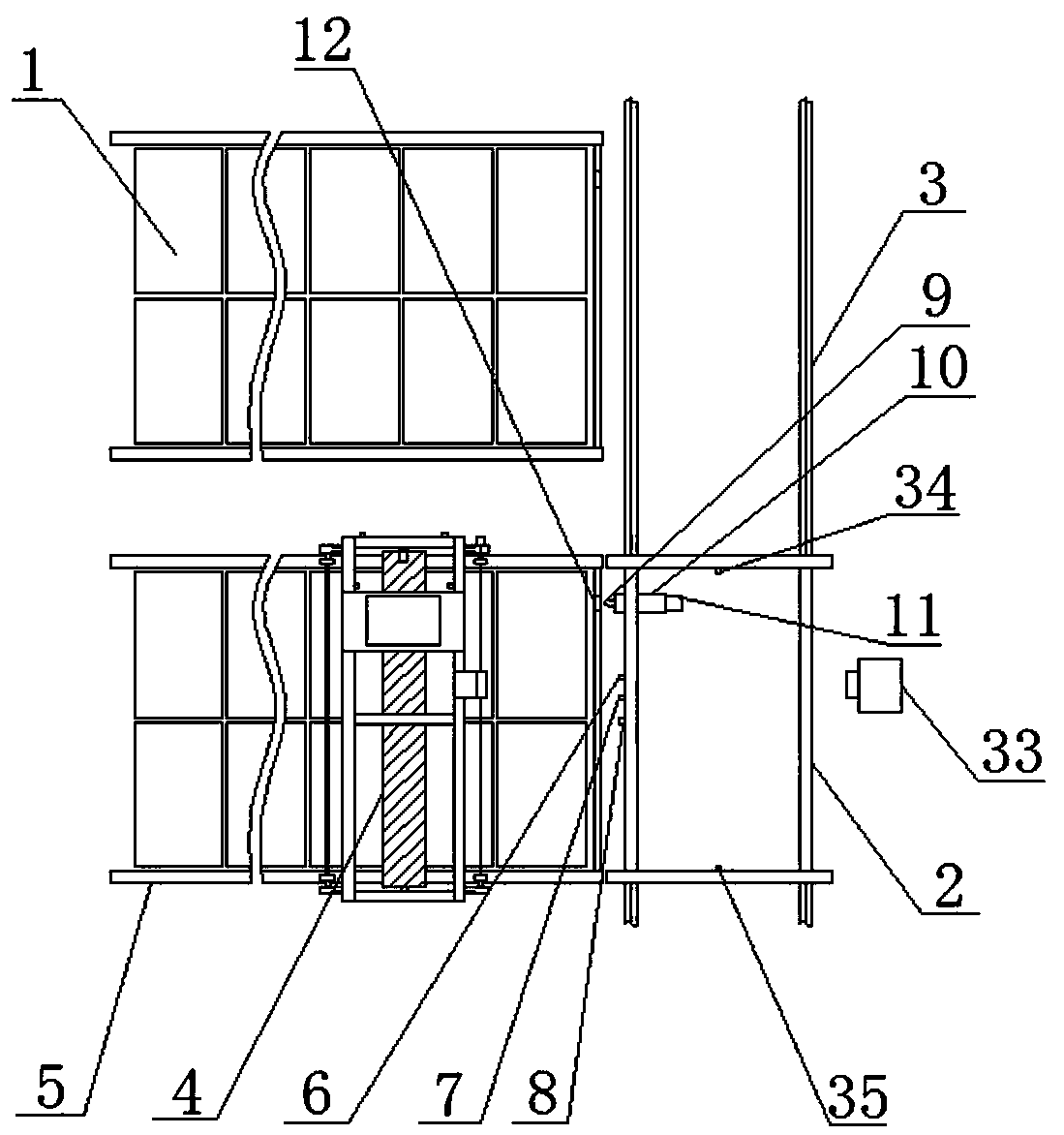

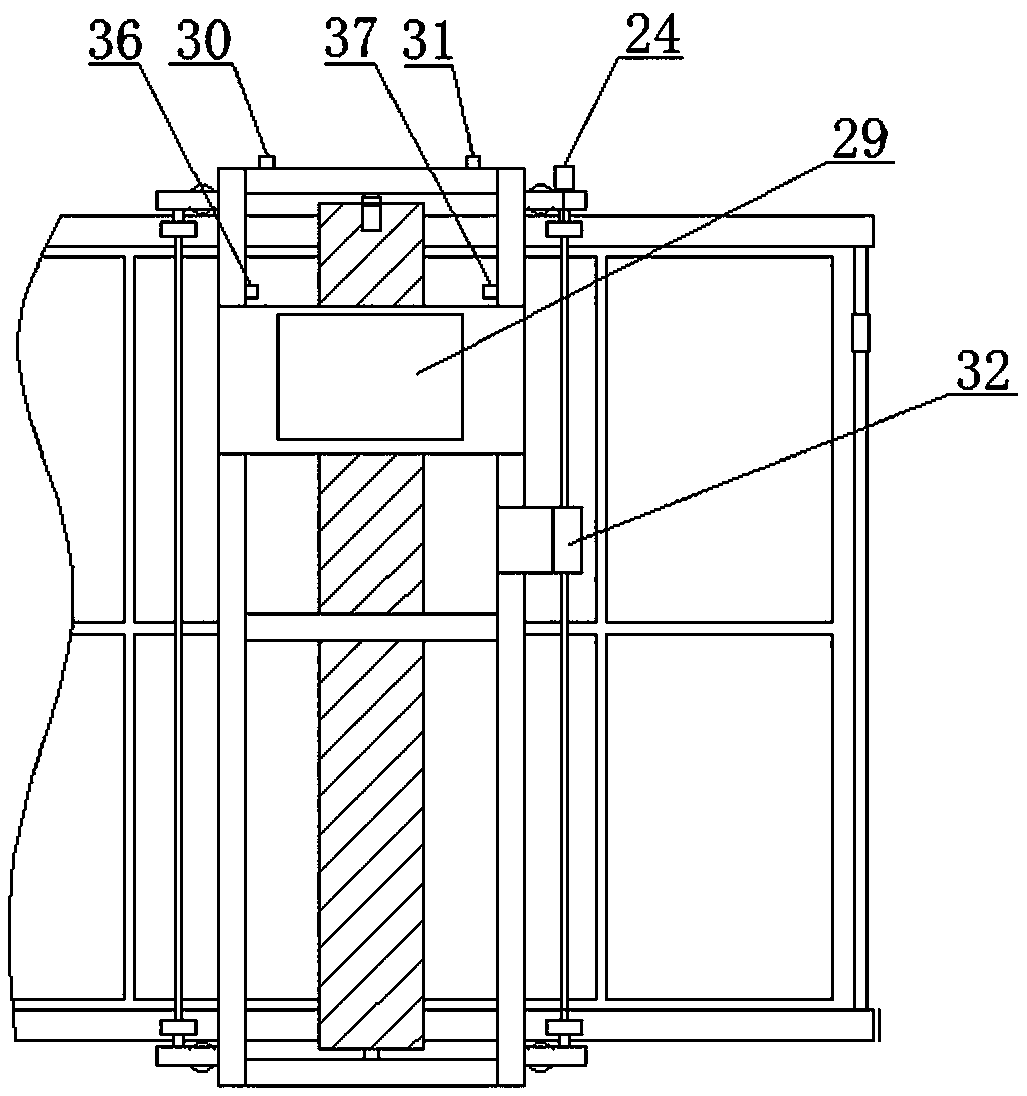

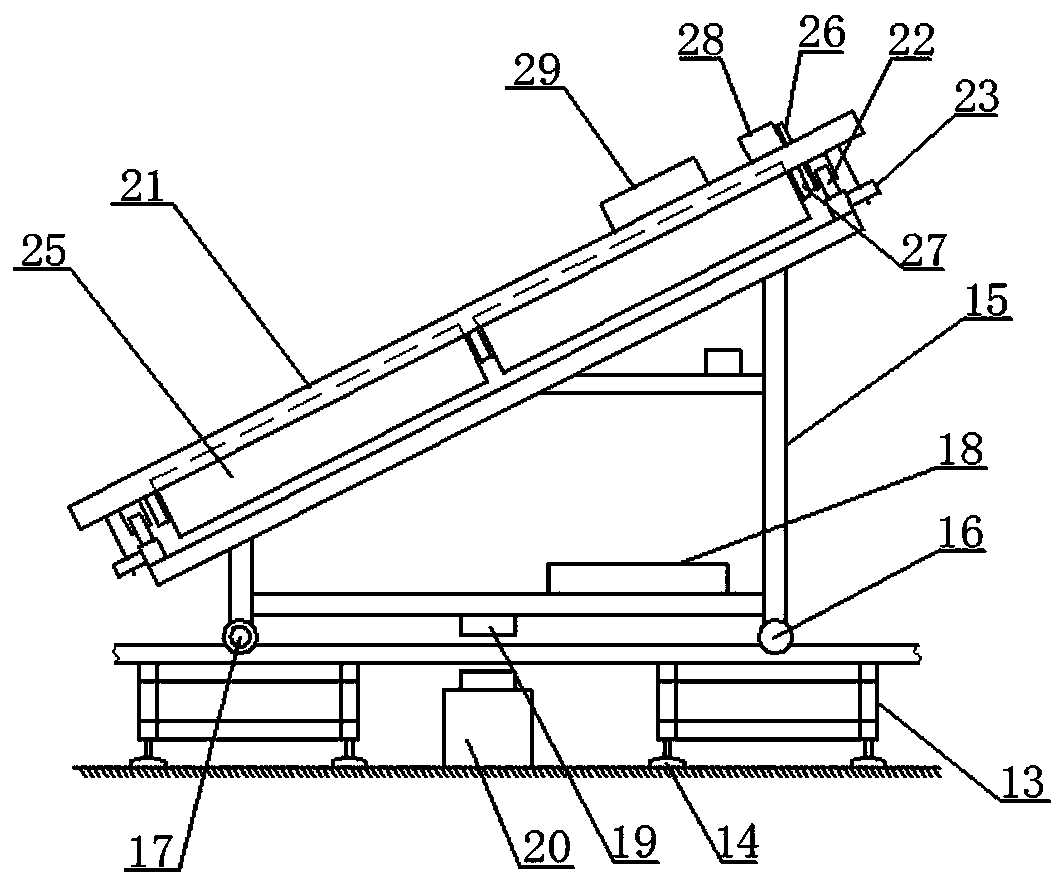

[0024] As shown in the figure, a photovoltaic module cleaning robot system that can automatically change rows according to the present invention includes several photovoltaic modules 1, a row-changing trolley 2, a row-changing track 3 and a cleaning trolley 4, several photovoltaic modules 1 are arranged in parallel, and two row-changing tracks 3 Parallel to each other and perpendicular to the photovoltaic module 1, they are arranged at one end of the photovoltaic module 1. The line-changing trolley 2 is arranged on the line-changing track 3 and can move along the line-changing track 3. The upper and lower ends of the photovoltaic module 1 and the line-changing trolley 2 are provided with corresponding The slide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com