A method for remediating cadmium-contaminated soil by symbiotic leaching

A cadmium-contaminated soil and cadmium-contaminated technology, which is applied in the field of soil remediation, can solve the problems of non-recyclable use, easy return of cadmium ions to the soil, and difficult treatment, so as to achieve remarkable soil remediation effects, overcome repeated cadmium pollution, and implement operation short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

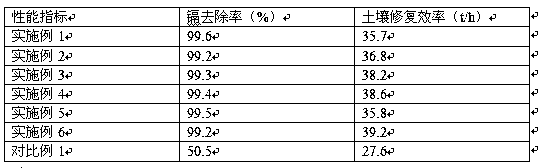

Examples

Embodiment 1

[0030] Mix 62kg of high-cadmium-polluted soil with 35kg of water and 3kg of zinc chloride, and add it to a forced mixer. The lifting speed of the hopper of the forced mixer is 20m / min. min, the power of the stirring motor is 33kW, and a vibrating rod is inserted to completely crush the gravel and sand in the soil to make a slurry, which is then added to a ball mill for wet grinding, and the cylinder speed is 26r / min to obtain fine Soil mud; then transfer the prepared soil mud to a filter with a mesh size of 130 μm, let it stand for 3 hours, so that free water is separated under the action of gravity to obtain the mud in a non-flowing state, and then use a filter with a filter area of 60m 2 A filter press with 40 filter chambers and a working pressure of 1.0 MPa performs further solid-liquid separation to achieve the purpose of soil cadmium removal; sodium hydroxide solution is added to the separated filtrate to form a cadmium hydroxide precipitate, Then filter and separate, ...

Embodiment 2

[0033] Mix 68kg of high-cadmium-contaminated soil with 30kg of water and 2kg of zinc sulfate, and add it to a forced mixer. The lifting speed of the hopper of the forced mixer is 18m / min, the power of the lifting motor is 5kW, and the rotation speed of the stirring shaft is 25r / min , the power of the stirring motor is 25kW, and a vibrating rod is inserted to completely crush the gravel and sand in the soil to make a slurry, and then put it into a ball mill for wet grinding, and the cylinder speed is 16r / min to make a fine soil Mud; then transfer the obtained soil slurry to a filter with a mesh size of 50 μm, let it stand for 4 hours, so that the free water is separated under the action of gravity, and obtain the mud in a non-flowing state, and then use a filter area of 40m 2A filter press with 30 filter chambers and a working pressure of 0.5 MPa performs further solid-liquid separation to achieve the purpose of soil cadmium removal; potassium hydroxide solution is added to th...

Embodiment 3

[0036] Mix 56kg of high-cadmium-contaminated soil with 40kg of water and 4kg of zinc nitrate, and add it to a forced mixer. The lifting speed of the hopper of the forced mixer is 25m / min, the power of the lifting motor is 10kW, and the rotation speed of the stirring shaft is 40r / min , the power of the stirring motor is 40kW, and a vibrating rod is inserted to completely crush the gravel and sand in the soil to make a slurry, and then put it into a ball mill for wet grinding, and the cylinder speed is 36r / min to make a fine soil Mud; then transfer the obtained soil slurry to a filter with a mesh size of 200 μm, let it stand for 2 hours, so that the free water is separated under the action of gravity, and obtain the mud in a non-flowing state, and then use a filter area of 80m 2 A filter press with 50 filter chambers and a working pressure of 1.6 MPa for further solid-liquid separation to achieve the purpose of removing cadmium from the soil; add barium hydroxide solution to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com