Full-automatic wire pipe welding machine

A fully automatic, welding machine technology, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of steel wire handling and storage, low qualified rate of welding products, shaking of welding electrodes, etc., to improve production efficiency and improve machinery Accuracy, to achieve the effect of full automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

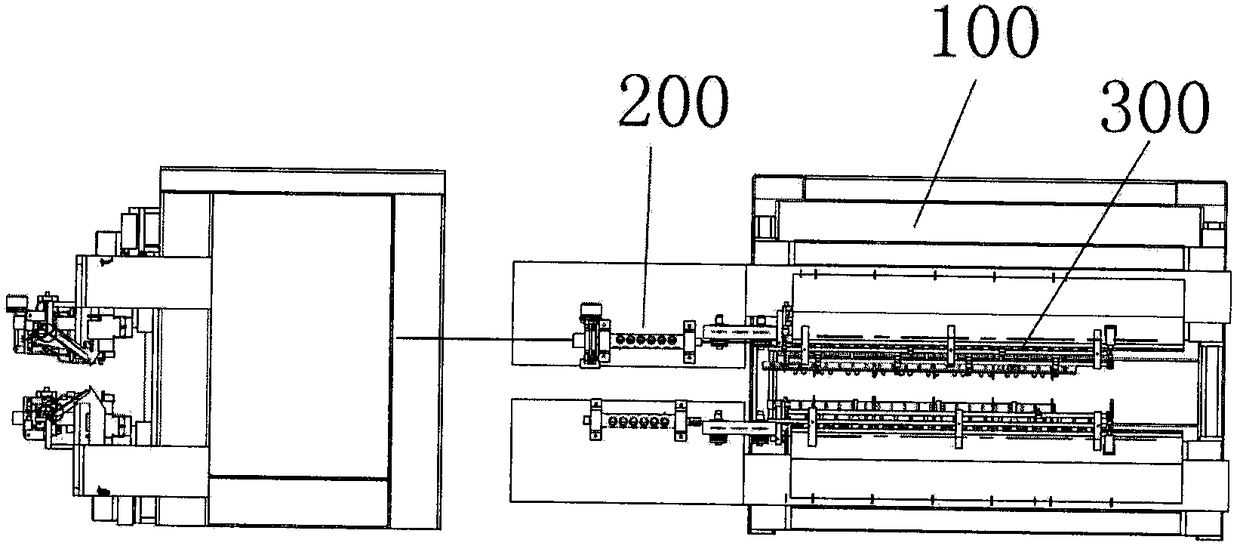

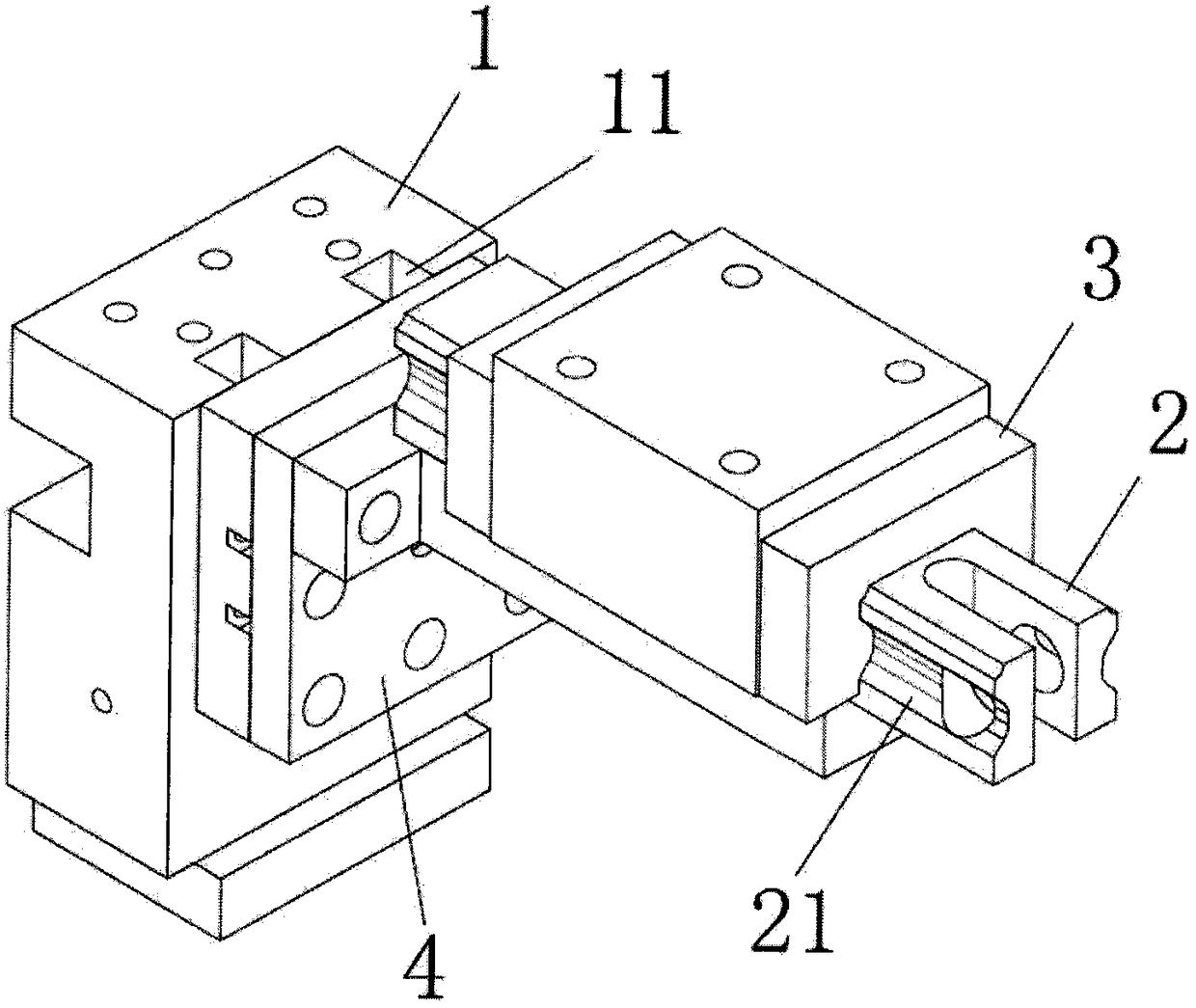

[0016] Such as figure 1 As shown, the fully automatic wire pipe welding machine includes a fully automatic welding machine frame assembly 100, and the fully automatic welding machine frame assembly 100 is also provided with a steel wire feeding and straightening steel wire assembly 200, online shearing steel wire and steel wire Launch the assembly 300, the steel wire turning mechanism assembly and the welding electrode assembly; the processing steps are as follows: a. According to the customer's drawing requirements, carry out online length fixing, straightening and cutting of the disc-shaped steel wire; b. The position of the cut steel wire is precisely regulated online; c. The steel wire after online cutting is sent online to the designated position of the formed steel pipe to be welded according to the process requirements for welding. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com