Welding technology of fuse element

A welding process and fuse technology, applied in welding equipment, manufacturing tools, resistance welding equipment, etc., can solve problems such as unstable product performance, low production efficiency, and unattractive appearance, and achieve good consistency, high production efficiency, and good appearance beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

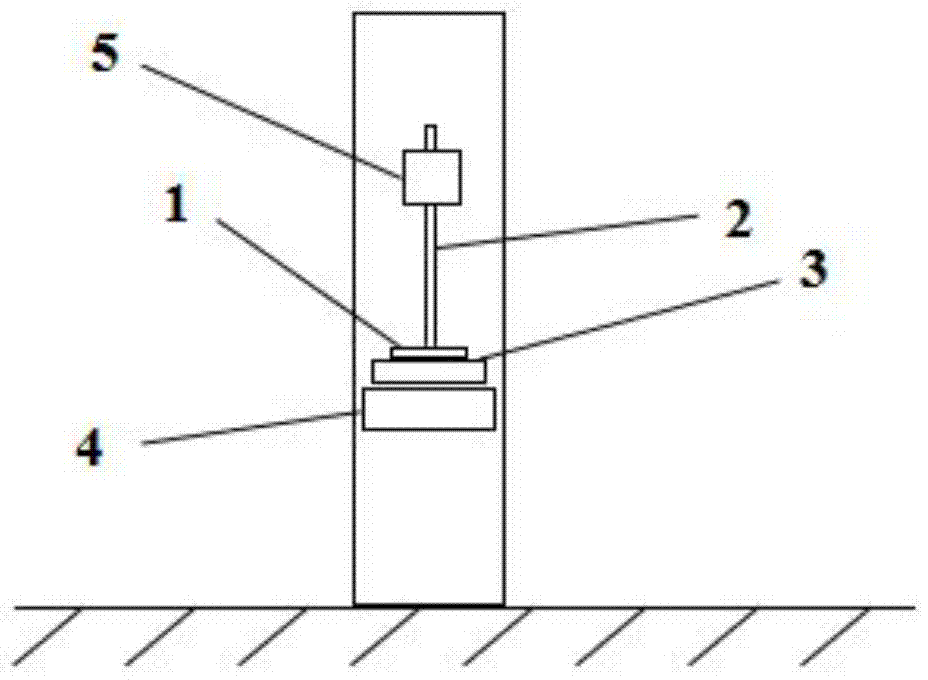

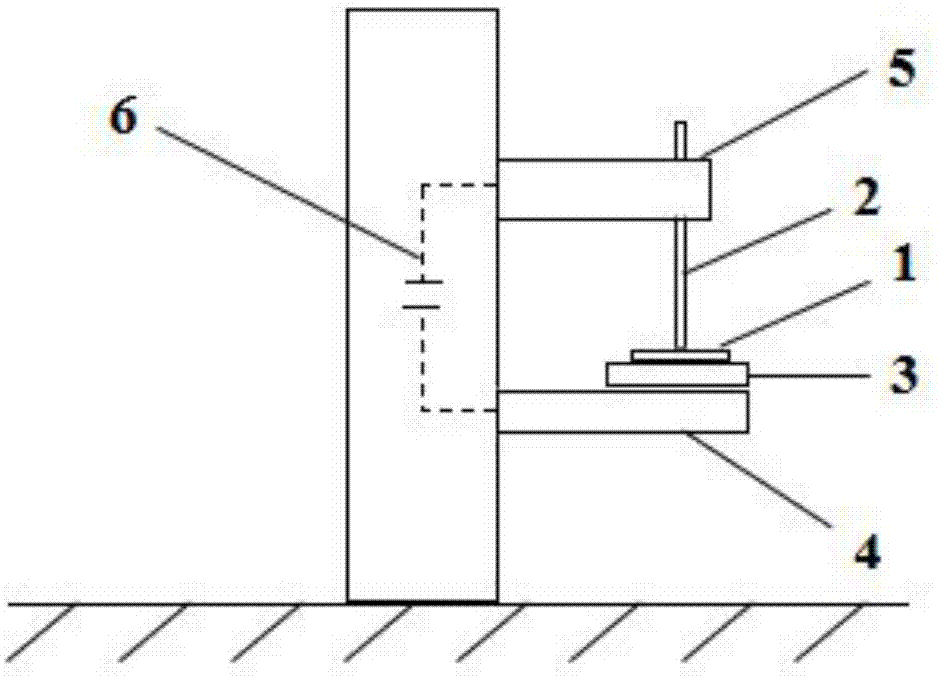

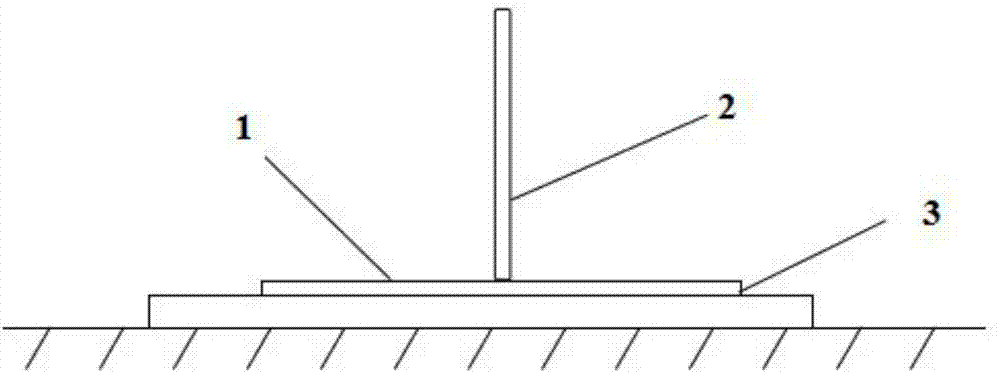

[0021] Attached below figure 1 , 2 , 3 the present invention is described in further detail:

[0022] A welding process for fuse elements, comprising the following steps:

[0023] (1) Choose a spot welding machine, place the melt to be welded and the conductive plate between the upper electrode and the lower electrode of the spot welding machine;

[0024] (2) Adjust the position of the welding head so that the lower electrode is in contact with the weldment and applies pressure;

[0025] (3) The contact surfaces of the two workpieces, the melt and the conductive plate, are heated through the circuit energization, and the local melting forms a nuclei, which need to move continuously and at a uniform speed during spot welding;

[0026] (4) Keep the pressure after the power is cut off to cool the nuclei under pressure, solidify to form solder joints, remove the pressure, take out the workpiece, and complete a welding process;

[0027] The melt is a flake or filament metal mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com