Device for machining high precision thickness spacer

A high-precision gasket technology, which is applied in metal processing equipment, manufacturing tools, and machine tools suitable for grinding workpiece planes, etc., can solve the problems of gasket thickness precision processing, etc., so as to reduce the production cost of enterprises and shorten the waiting time , Obvious effect of social benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with embodiment, but not as any limitation to the present invention.

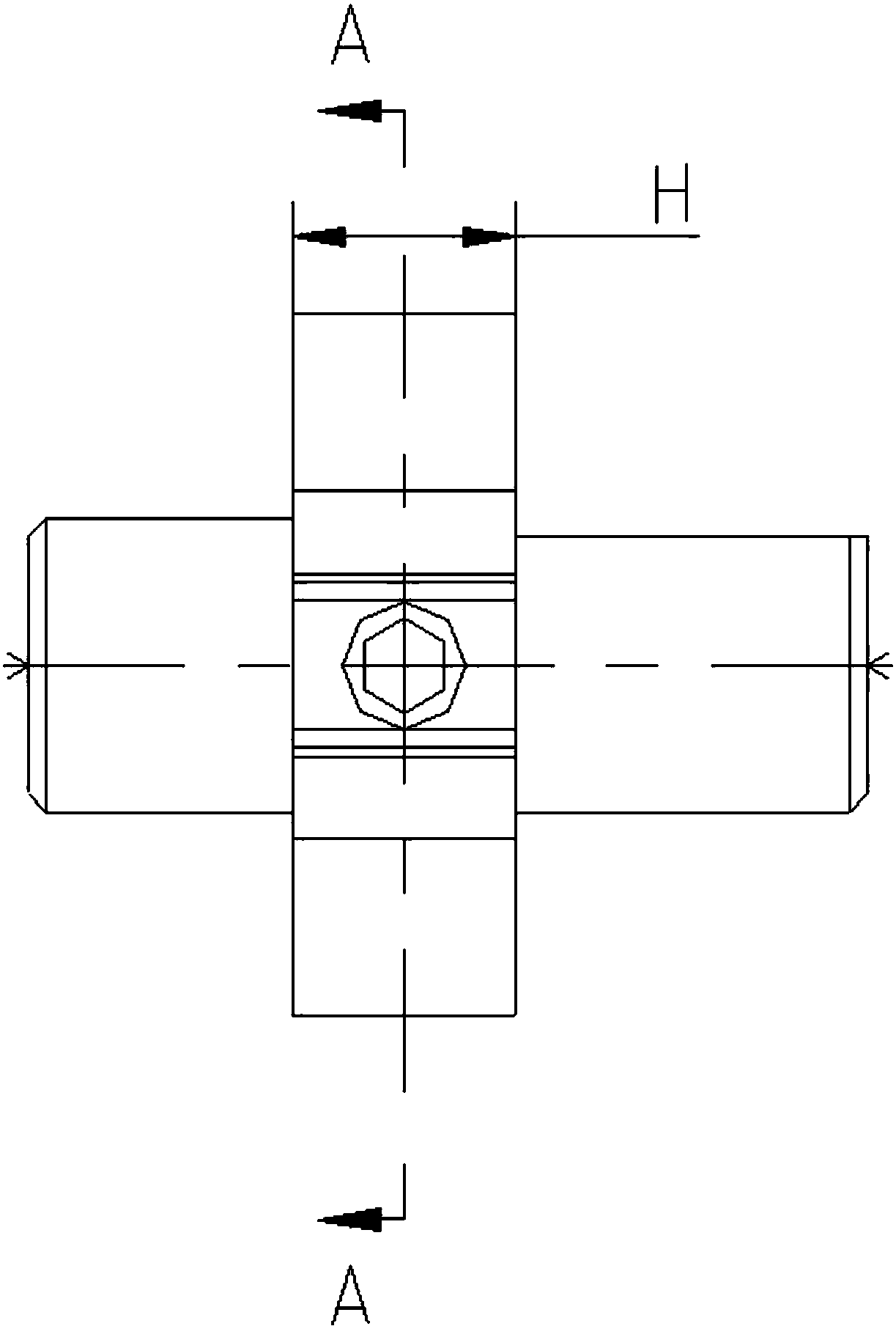

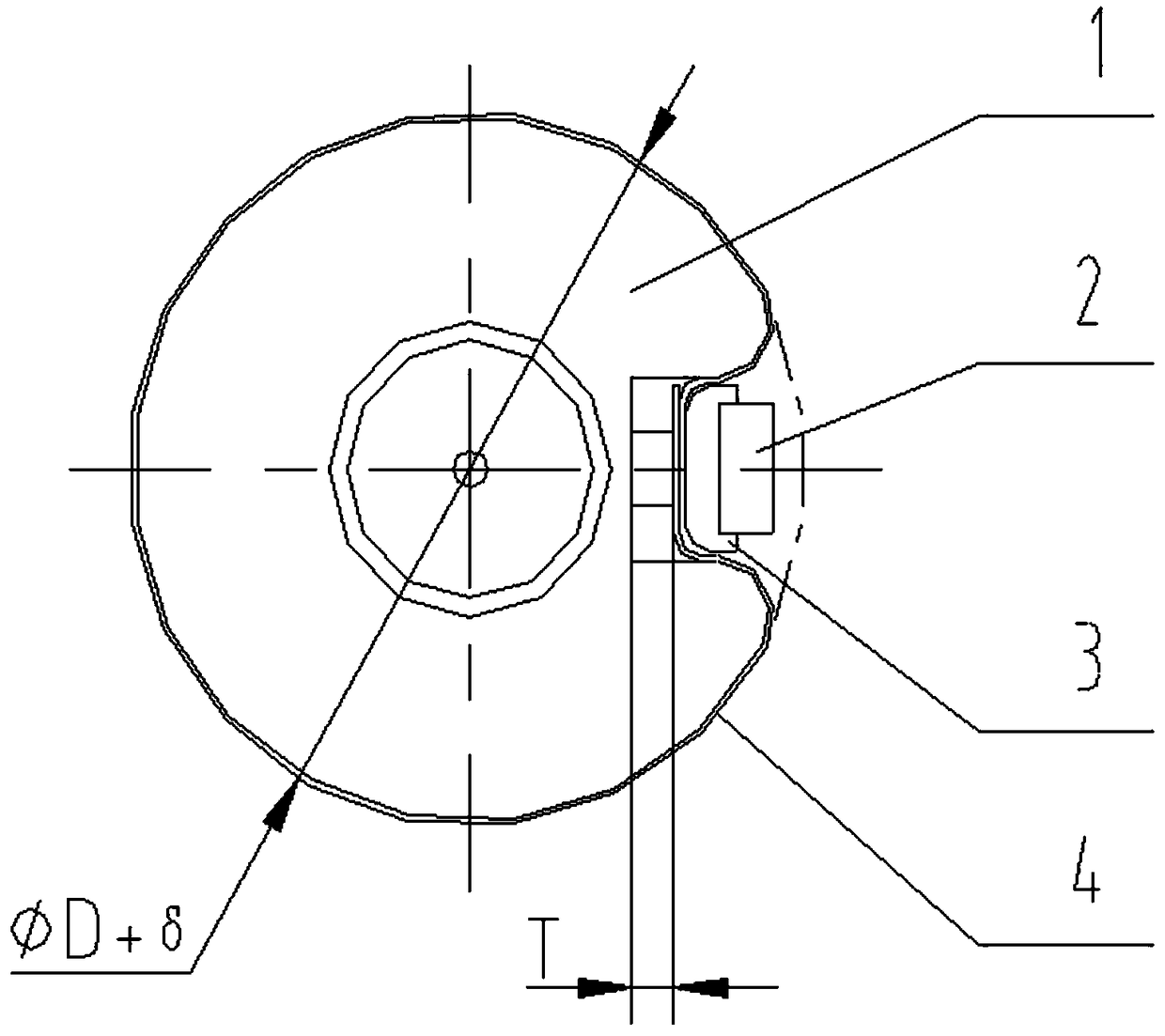

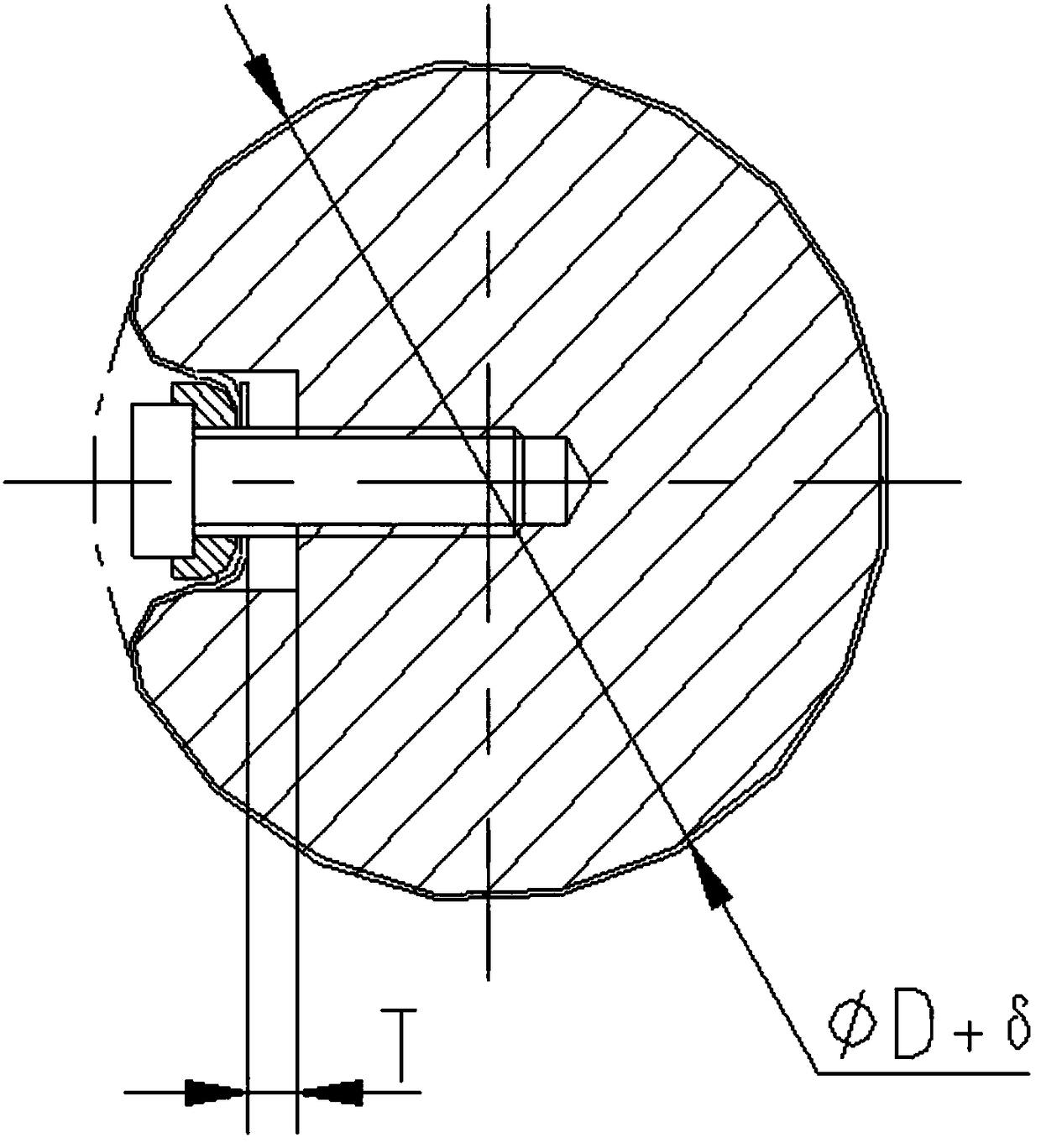

[0019] see Figure 1-9 : This device comprises a cylindrical mandrel 1, has groove in the side of this cylindrical mandrel 1, is provided with briquetting block 3 and screw 2 in the groove, is provided with on the briquetting block 3 and in the groove of cylindrical mandrel 1 Screw holes for screws 2 to be screwed into. Specifically, calculate π·D according to the required length of the gasket 4 to determine the diameter D of the cylindrical mandrel 1; determine the width H+2 of the cylindrical mandrel 1 according to the required width H of the gasket 4. In addition, both ends of the cylindrical mandrel 1 are provided with central holes, and the hardness is HRC>45.

[0020] In order to better illustrate the device of the present invention, the processing Figure 8 and Figure 9 The high-precision gasket 4 shown as an example, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com