A method and device for preventing accumulation and explosion of hydrocarbon compounds

A compound and hydrocarbon technology, applied in the field of coal-to-synthesis ammonia air separation system, can solve the problems of long maintenance time and great impact on production line operation, achieve good economic benefits, solve the bottleneck of equipment explosion affecting the normal production of the system, and avoid equipment explosion. Dangerous effects of explosion accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

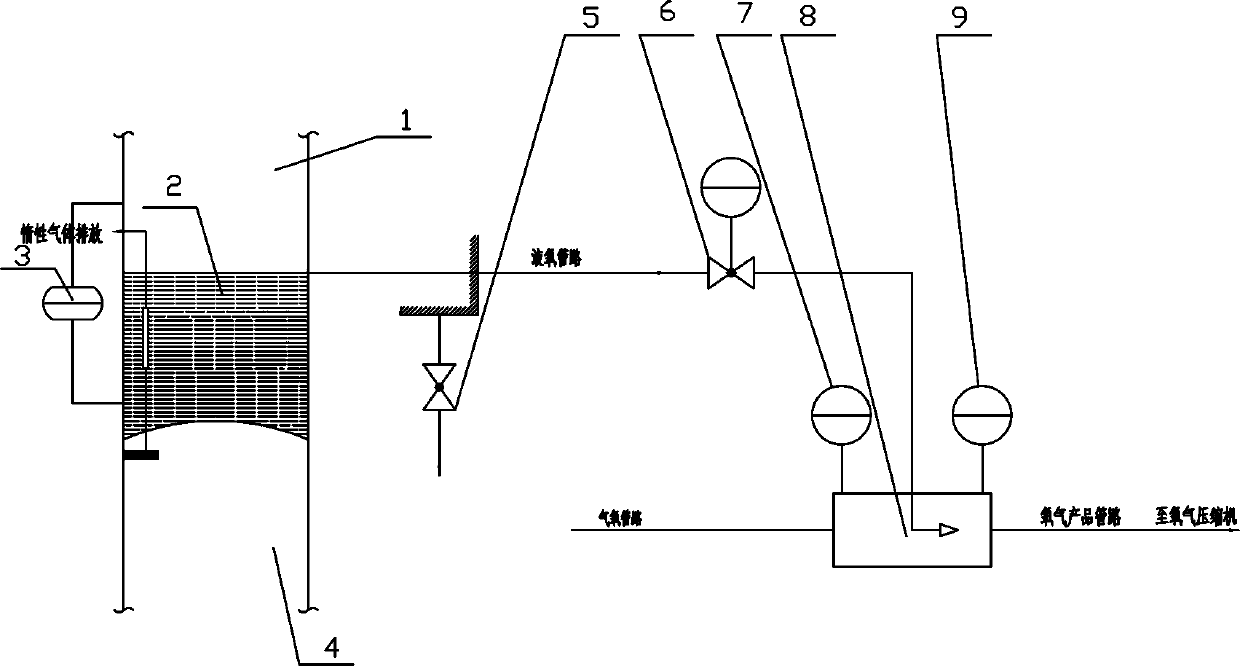

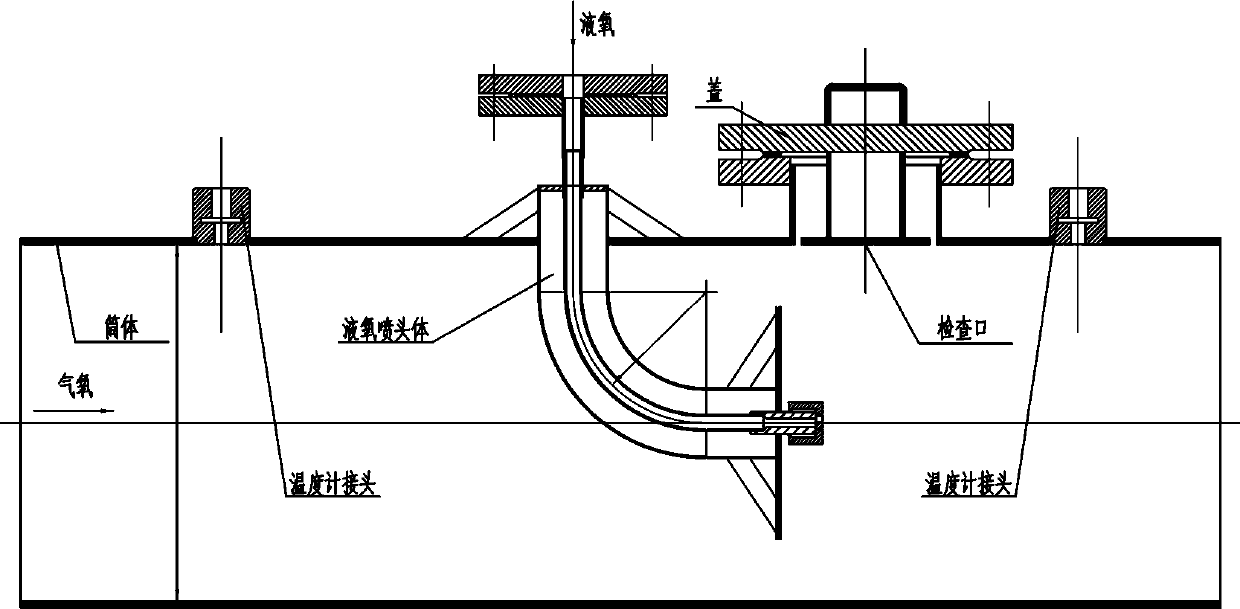

[0020] When the system of the present invention is working, the air is successively filtered by a filter, compressed by an air compressor, cooled and defogged by a water cooler, condensed water is removed by an ammonia evaporator, moisture and carbon dioxide are removed by an adsorber, and then cooled by a heat exchanger to lower its temperature. To -172 ℃, the pressure reaches 0.55MPa, the air close to the saturated state enters the air separation rectification tower, and the rising gas in the tower is partially condensed for many times and the descending liquid is evaporated for many times through the main cooling evaporator 2. The gas first Rough rectification is carried out in the lower tower 4 of the air separation two-stage rectification tower, and then through the rectification of the upper tower 1 of the air separation two-stage rectification tower, the double high-purity products of oxygen and nitrogen are obtained in the upper tower, that is, in the upper tower The bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com