TRIZ (theory of inventive problem solving)-based injection mechanism for injection molding machine

A technology of injection molding machine and injection cylinder, applied in the field of injection mechanism of injection molding machine based on TRIZ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

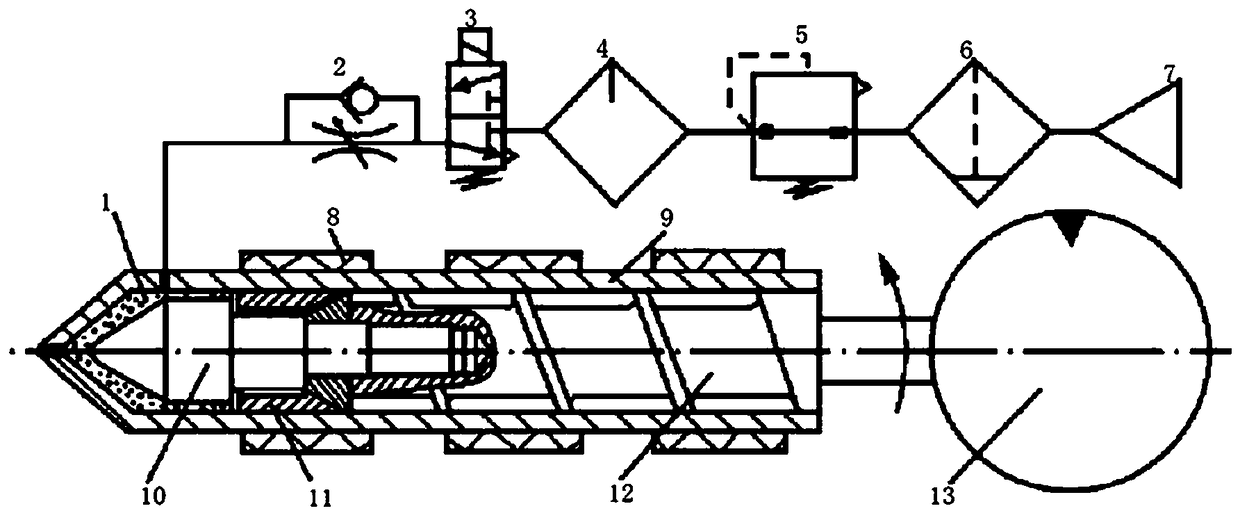

[0017] The injection molding machine is mainly composed of an injection device and a hydraulic transmission system. Among them, the injection device is composed of a plasticizing device, a hopper, a metering device, a screw drive device, and an injection cylinder. The hydraulic transmission system is mainly composed of hydraulic pumps, hydraulic valves, flow valves, pressure valves and other components.

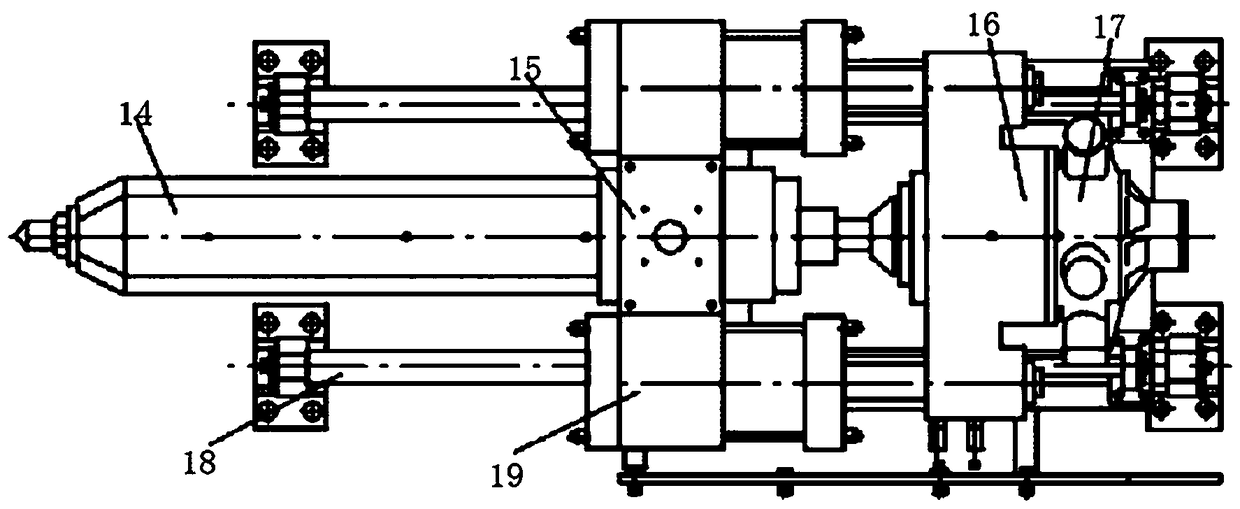

[0018] Such as figure 2 As shown, through the investigation of the operation of the injection molding machine in actual production, it is found that the hydraulic system, injection mechanism and mold temperature control process of the injection molding machine currently have the following problems: (1) Due to the needs of the molding process and different production processes, the injection molding machine is The flow and pressure required in the working process are often different and often change. Generally, different combinations of quantitative pumps (dual pump oil supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com