High-speed train wind resistance braking device

A technology for wind resistance braking and high-speed trains, which is applied in the fields of pneumatic brakes, transportation and packaging, railway car body parts, etc. It can solve the problems that cannot meet the braking conditions, do not involve multi-angle locking scheme design, and the oil leakage of hydraulic cylinders is difficult to maintain and other problems, to achieve the effect of fast emergency braking response, light weight, and fast opening speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

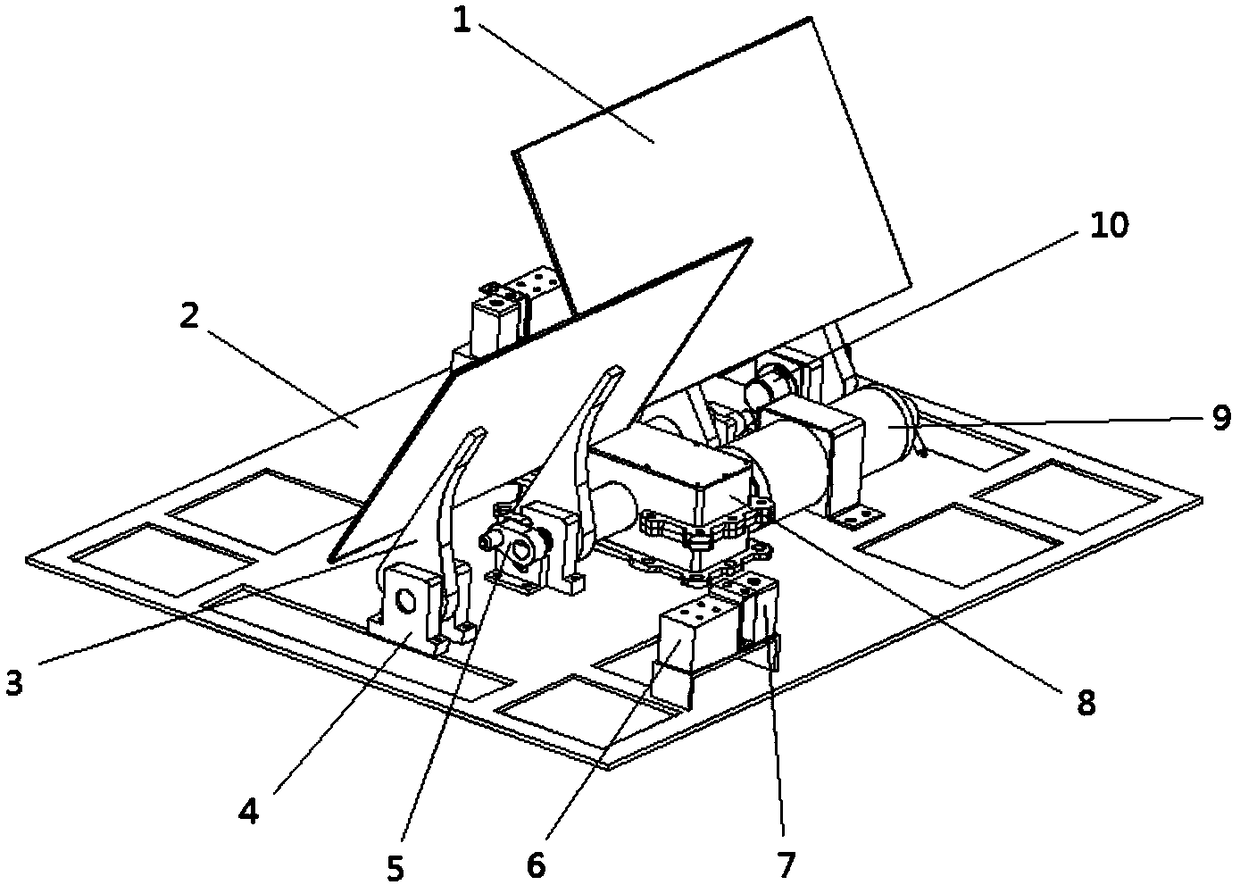

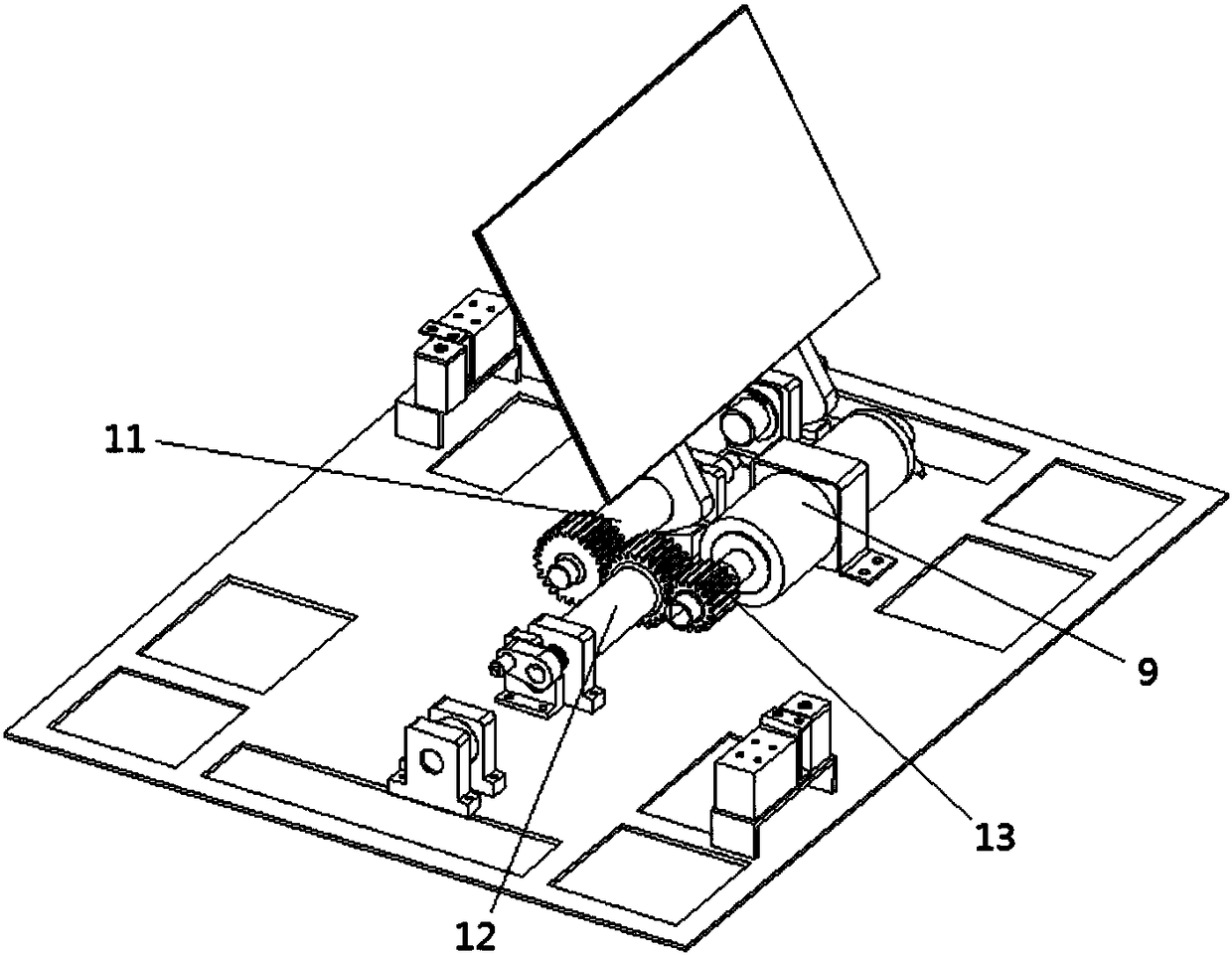

[0024] The common braking working principle of the wind resistance braking device is as follows: when the wind resistance braking device needs to implement normal braking, according to the output signal of the braking system controller, the locking device 6 is unlocked, and the opening mechanism 7 will brake the wind vane 1 Open a small angle, the motor 9 rotates forward, and the transmission gear shafts on both sides drive the brake wind vane 1 to open in the opposite direction; when providing stable normal braking deceleration, according to the output signal of the brake system controller and the angle sensor 10 , the motor 9 stalls, the gear shafts on both sides stop rotating, and the brake wind vane 1 is fixed at an angle, thereby realizing the function of locking the brake wind vane 1 and the bottom plate 2 of the box at any angle within 0-75 degrees.

Embodiment 2

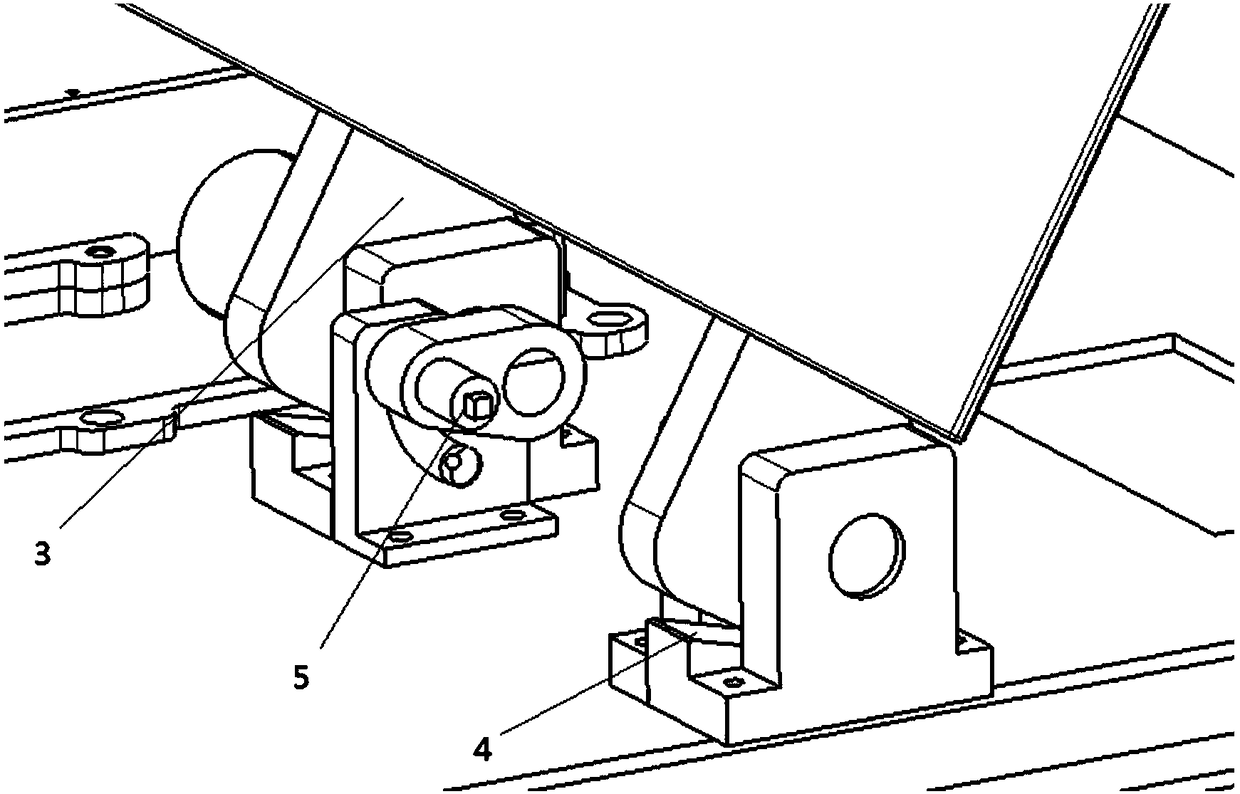

[0026] The emergency braking working principle of the wind resistance braking device is as follows: when the braking system controller outputs a signal or the vehicle loses power, the present invention implements the emergency braking locking device 6 to unlock, and the opening mechanism 7 is triggered to brake the wind vane 1 Open a small angle, drive the brake wind vane 1 to open in the opposite direction by the walking wind, when reaching the maximum angle, the stop part (slope surface) of the stop bearing seat 4 prevents the rocker arm 3 from rotating beyond the maximum angle, and the locking mechanism 5 The rotation angle error is limited to no more than one degree, so under emergency braking conditions, the brake wind vane 1 is directly opened to 75 degrees and locked.

[0027] The recovery working principle of the wind resistance brake device is as follows: when there is no need to brake, the motor 9 reverses, the gear shafts on both sides drive the brake wind vane 1 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com