Rapid boxing mechanism of ceramic tile stacking-boxing arrangement machine and working method of rapid boxing mechanism

A technology for finishing machines and tiles, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of manual packaging, high labor intensity, low efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples, but the embodiments of the present invention are not limited thereto.

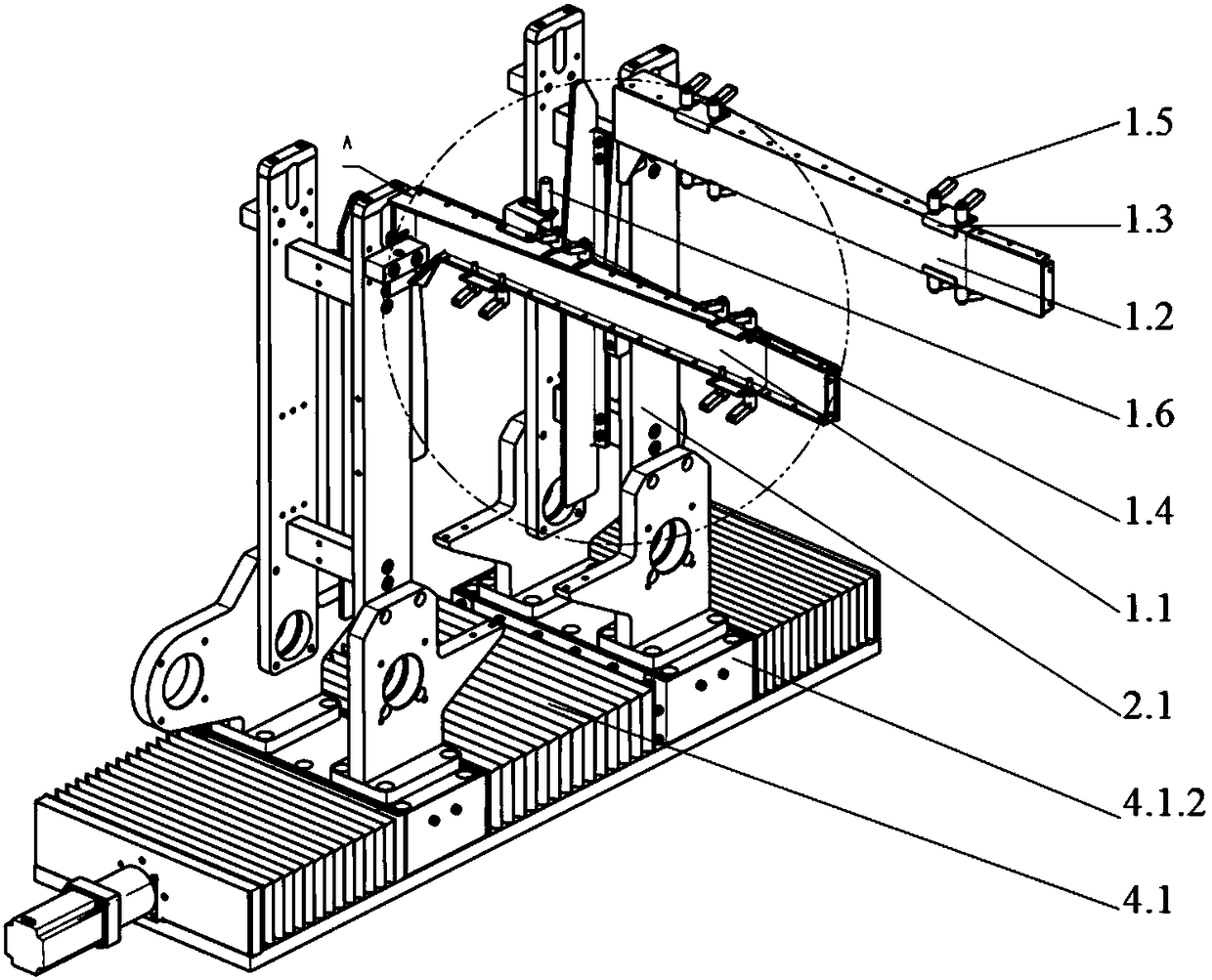

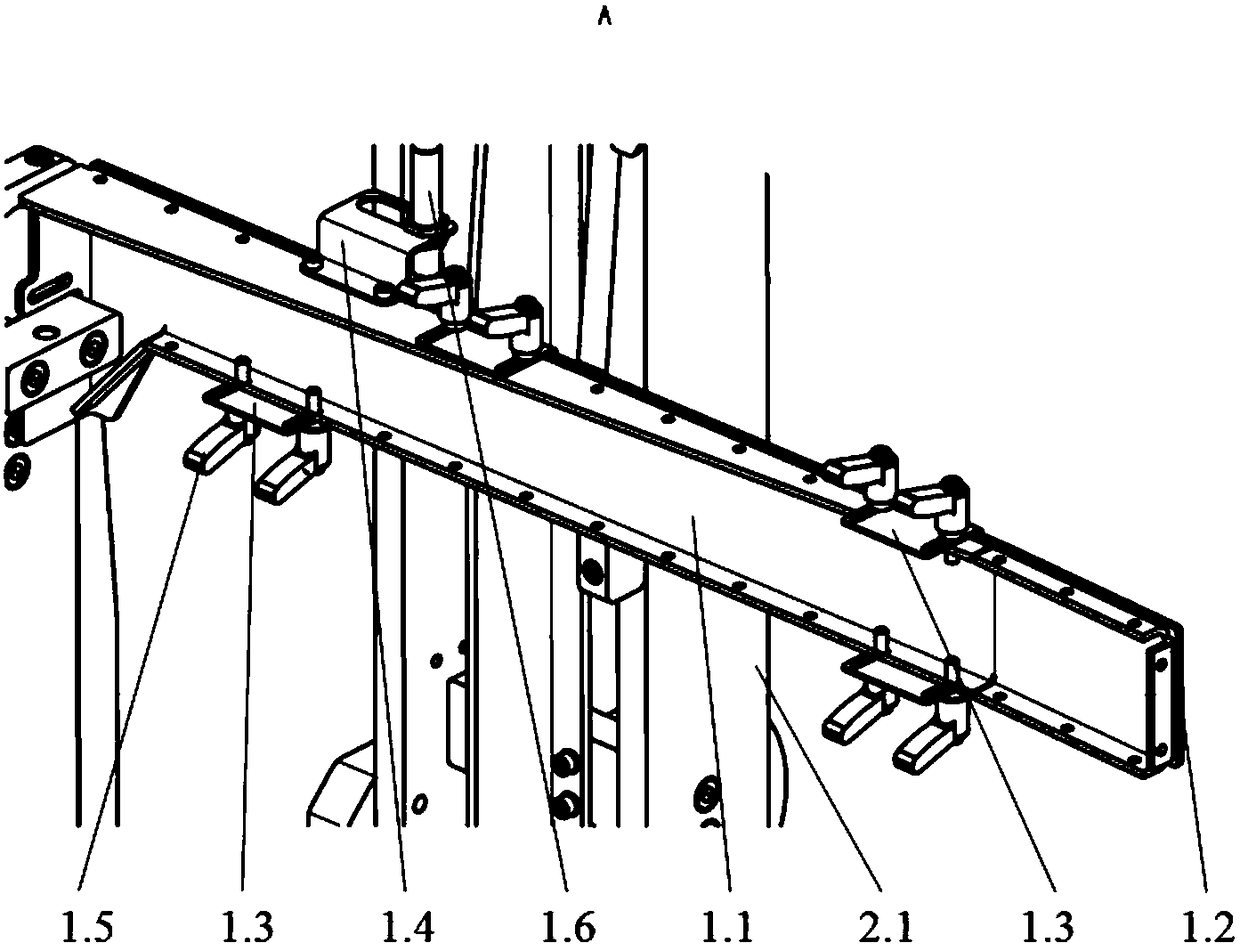

[0043] In the present invention, the traveling direction of the tiles is taken as the front, and the opposite side of the two stacking brick racks 2.1 erected in parallel is the inner side, and vice versa is the outer side.

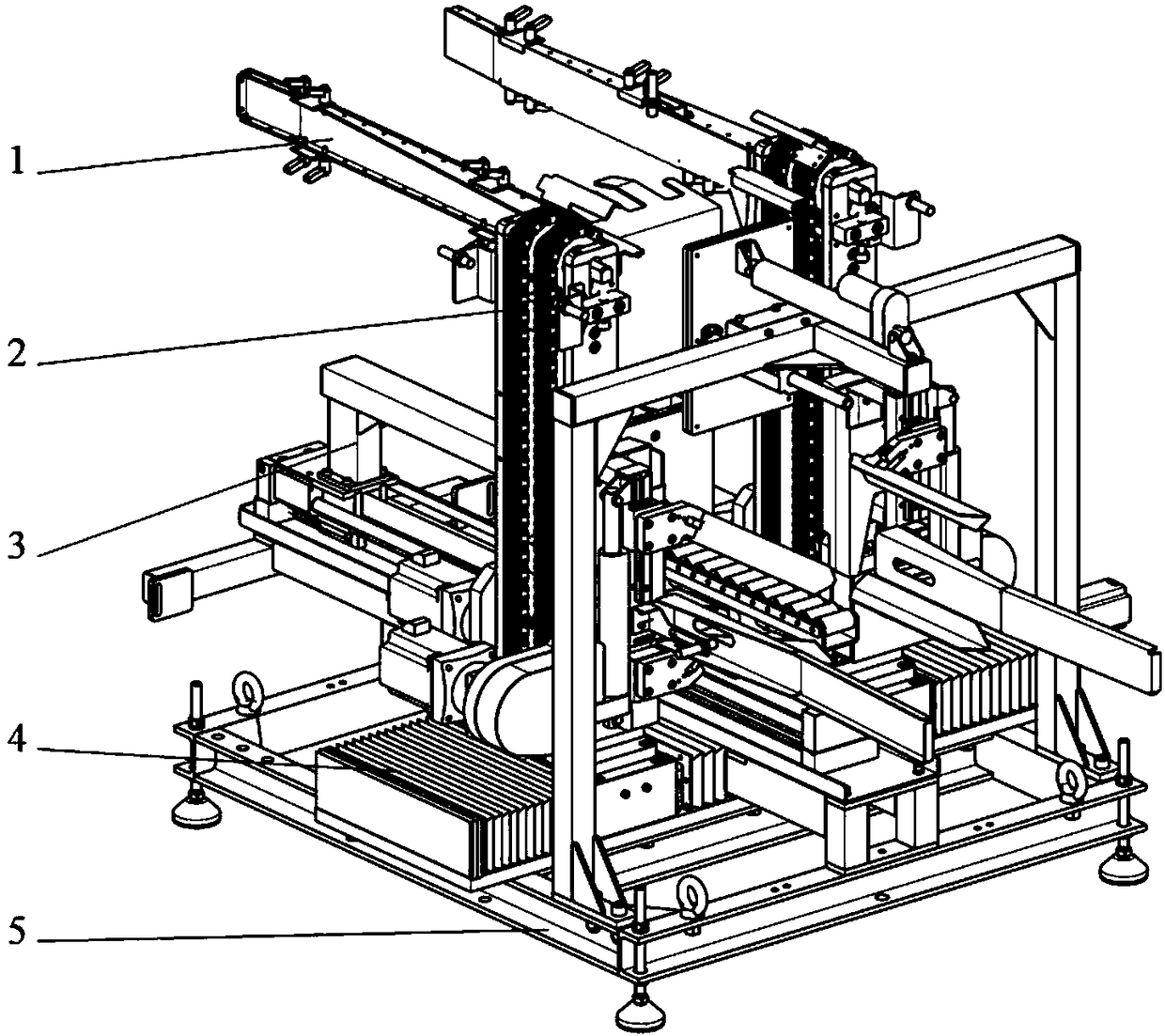

[0044] Such as Figure 1-Figure 17 As shown, the ceramic tile stacking brick-boxing finishing machine of the present invention includes five major parts, which are respectively a preliminary finishing mechanism 1, a continuous brick stacking mechanism 2, a fast packing mechanism 3, a parameter adjustment mechanism 4 and a base 5. The mechanism 1 is installed on the continuous brick stacking mechanism 2, and is located on the side of the direction of the tiles. The brick stacking frame 2.1 and the front baffle layer 2.10 in the continuous brick stacking mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com