Serpentine/functionalized graphene lubricating oil additive, preparation method and application thereof

A technology of graphene lubricating oil and serpentine is applied in the field of lubricating oil to achieve the effects of simple operation, high diffusivity and reduced friction coefficient in the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

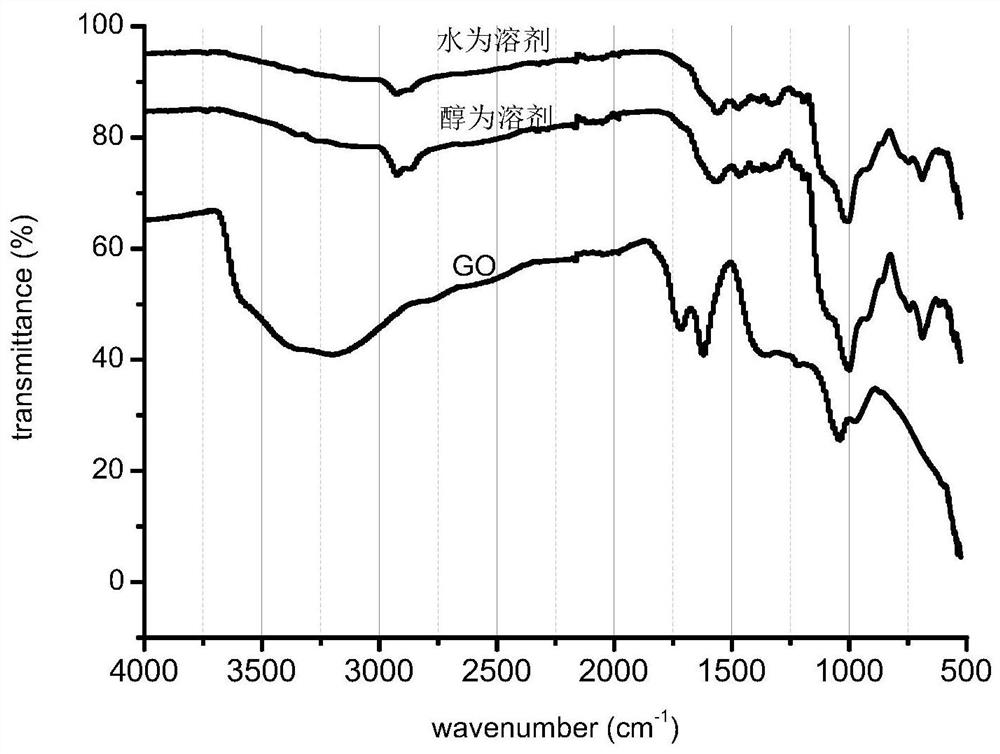

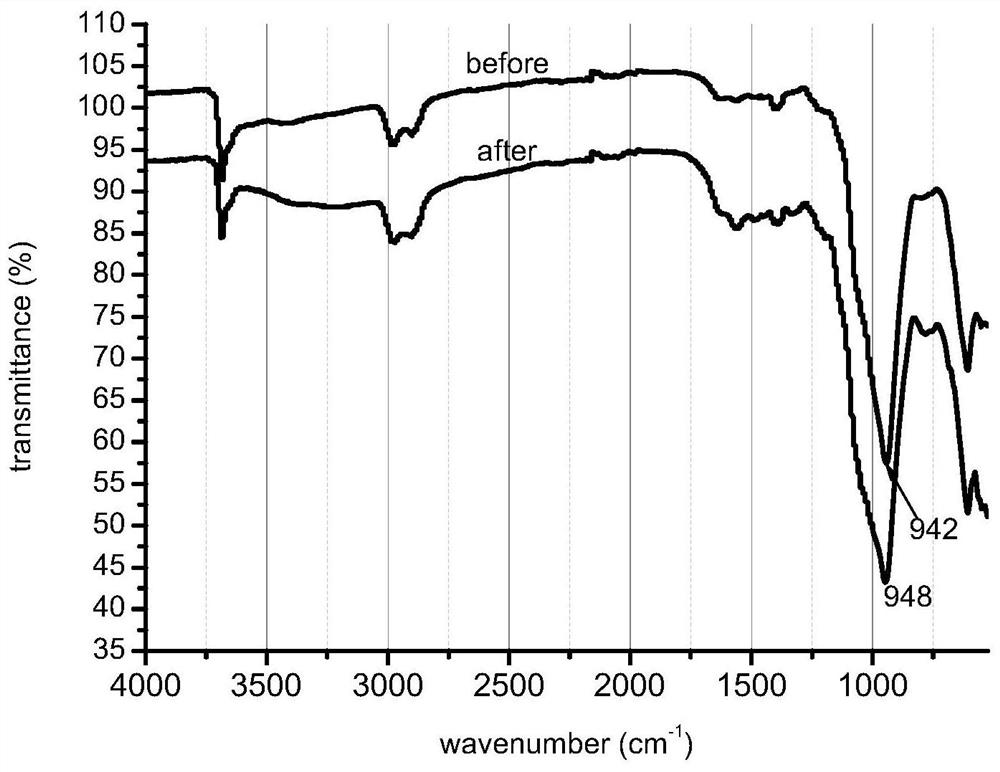

[0023] (1) Graphene oxide prepared by the improved Hummers method is used as a raw material, and the obtained graphene oxide is modified with a silane coupling agent. First, weigh 1.6 g of 2.5 wt% graphene oxide aqueous solution, add 150 mL of deionized water to dilute and ultrasonically disperse evenly. Then, 6 mL of silane coupling agent (A-1100) was added dropwise, and magnetically stirred for 1 h at room temperature. Finally, it was transferred to a flask and reacted in a water bath at 80 °C for 2 h. Let it stand for cooling, centrifuge, wash with water and add appropriate amount of deionized water to obtain a functionalized graphene oxide dispersion. figure 1 It is graphene oxide and functionalized graphene oxide infrared spectrum, it can be seen from the spectrum that functionalized graphene oxide has been successfully prepared.

[0024] (2) Weigh 0.08 g of serpentine nanopowder, dissolve it in the above-mentioned functionalized graphene oxide dispersion liquid; stir i...

Embodiment 2

[0028] (1) Graphene oxide prepared by the improved Hummers method is used as a raw material, and the obtained graphene oxide is modified with a silane coupling agent. First, weigh 1.6 g of 2.5 wt% graphene oxide aqueous solution, add 150 mL of deionized water to dilute and ultrasonically disperse evenly. Then, 3 mL of silane coupling agent (KBM-602) was added dropwise, and magnetically stirred for 1 h at room temperature. Finally, it was transferred to a flask and reacted in a water bath at 80 °C for 2 h. Let it stand for cooling, centrifuge, wash with water and add appropriate amount of deionized water to obtain a functionalized graphene oxide dispersion.

[0029] (2) Weigh 0.08 g of serpentine nanopowder, dissolve it in the above-mentioned functionalized graphene oxide dispersion liquid; stir it magnetically for 60 min; Separate, wash with water and ethanol respectively, and dry to obtain serpentine / functionalized graphene lubricating oil additive powder.

[0030] (3) Tri...

Embodiment 3

[0033] (1) Graphene oxide prepared by the improved Hummers method is used as a raw material, and the obtained graphene oxide is modified with a silane coupling agent. First, weigh 1.6 g of 2.5 wt% graphene oxide aqueous solution, add 150 mL of deionized water to dilute and ultrasonically disperse evenly. Then, 8 mL of silane coupling agent (A-1110) was added dropwise, and magnetically stirred at room temperature for 0.5 h. Finally, transfer it to a flask, react in a water bath at 60 °C for 1 h, and let it stand for cooling; centrifuge, wash with water, and add an appropriate amount of absolute ethanol to obtain a functionalized graphene oxide dispersion.

[0034] (2) Weigh 0.32 g of serpentine nanopowder, dissolve it in the above-mentioned functionalized graphene oxide dispersion; stir it magnetically for 30 min; Cooling; centrifugal separation, washing with water and ethanol respectively, and drying to obtain serpentine / functionalized graphene lubricating oil additive powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com