Process for integrally assembling multilayer steel anchor beams of main towers of cable-stayed bridges

A technology for steel anchor beams and cable-stayed bridges, used in bridges, bridge parts, bridge materials, etc., can solve the problems of inconvenient hoisting, troublesome modification, hidden safety hazards, etc., so as to save the inconvenience of modification, reduce workload, labor safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

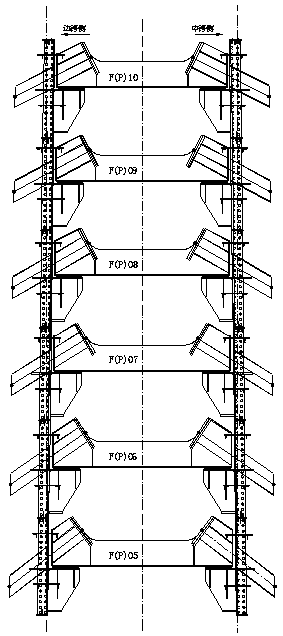

[0025] The overall assembly process of the multi-layer steel anchor beam of the main tower of the cable-stayed bridge of the present invention: the multi-layer steel anchor beam as a whole includes six layers of steel anchor boxes distributed sequentially from bottom to top, and are sequentially numbered as FP05, FP06, FP07, FP08, FP09 , FP10, such as figure 1 As shown, each layer of steel anchor box includes a steel anchor beam and the steel corbels set up on the left and right to support the steel anchor beam. To be realized, the specific steps are:

[0026] The first step, a pre-assembly: First, normal pre-assembly of the single-layer steel anchor beam, and adjust the anchor point of the steel anchor beam to the best position according to the alignment line of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com