Clearing method of contaminants in casting inner cavity

A technology of casting inner cavity and cleaning method, which is applied in the field of cleaning pollutants in the inner cavity of castings, can solve the problems of long time consumption, large limitations, incomplete cleaning of castings by molding sand, etc., and achieves the effect of simple operation method and safe working conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

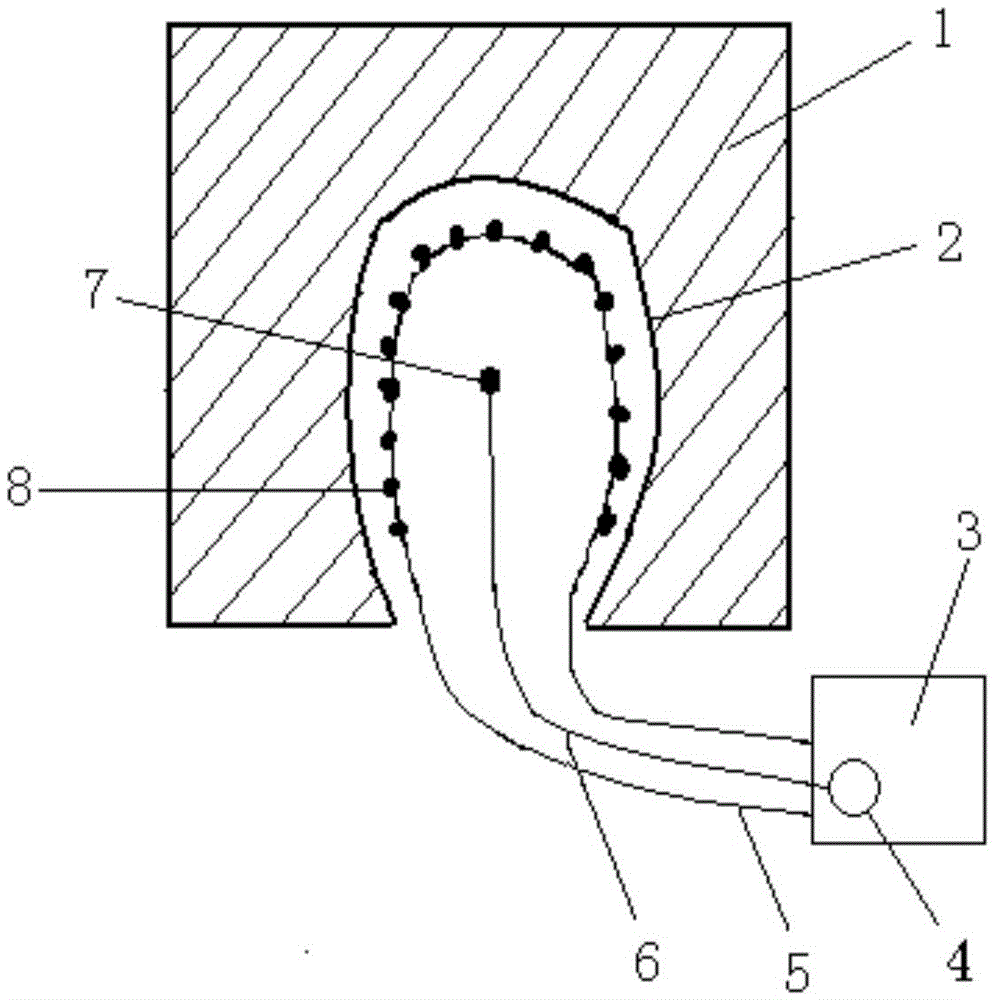

[0015] Such as figure 1 As shown, a method for cleaning the pollutants in the inner cavity of a casting is provided, which is characterized in that it includes an elastic soft bag 5, a pressurizing device 3, a rotating device 4, and a flexible shaft 6; the flexible shaft 6 is a rubber rod, and the pressurizing part 3 can Inflate the elastic soft bag 5, the rotating part 4 is connected with one end of the flexible shaft 6, and can drive the flexible shaft 6 to rotate, and the other end of the flexible shaft 6 is fixed with an eccentric steel ball; the elastic soft bag 5, the flexible shaft 6 and the eccentric steel ball 7 can be put into into the inner cavity 2 of the casting 1, and the flexible shaft 6 and the eccentric steel ball 7 are in the cavity of the elastic soft bag 5;

[0016] The method includes the following steps: after putting the elastic soft capsul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com