Brake band for speed reduction clutch

A technology of deceleration clutch and brake belt, applied in the direction of brake parts, brake types, brake components, etc., can solve the problem that the effective joint surface of the brake belt and the brake hub cannot be fully implemented, the vibration of the brake belt and the brake hub noise, Affect the normal use of the deceleration clutch, etc., to reduce the low life of the steel belt, prevent noise, and not easily deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

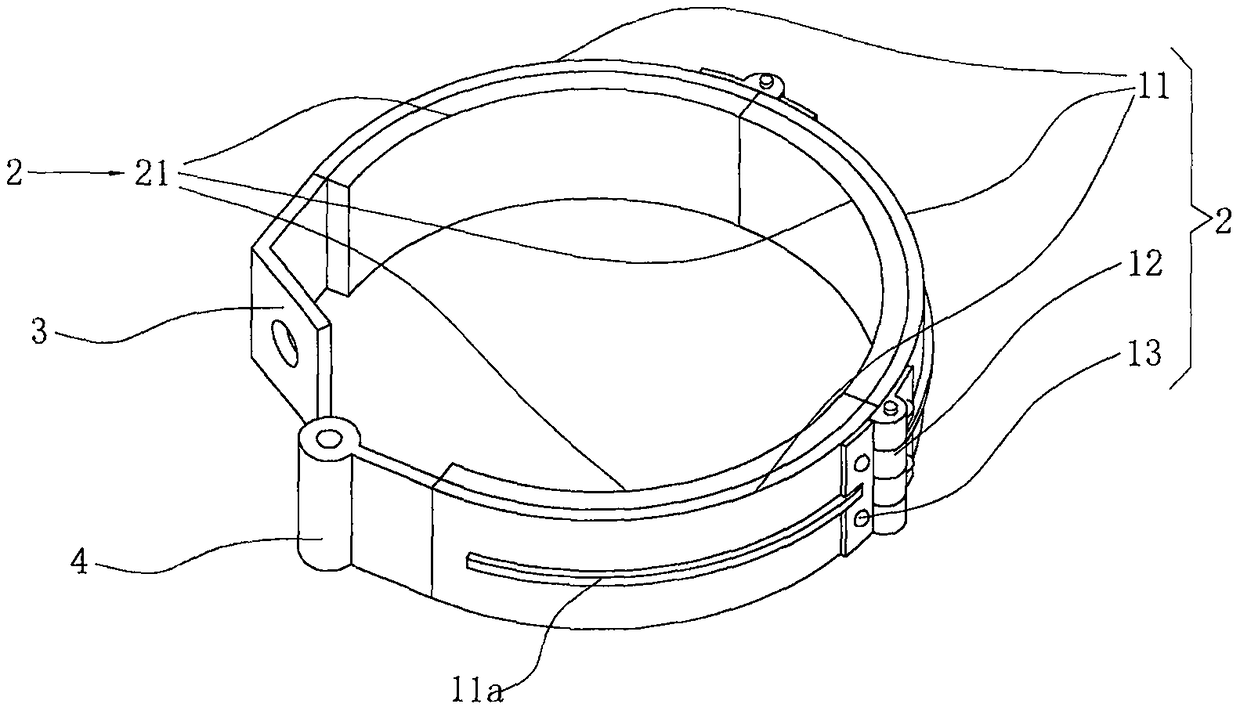

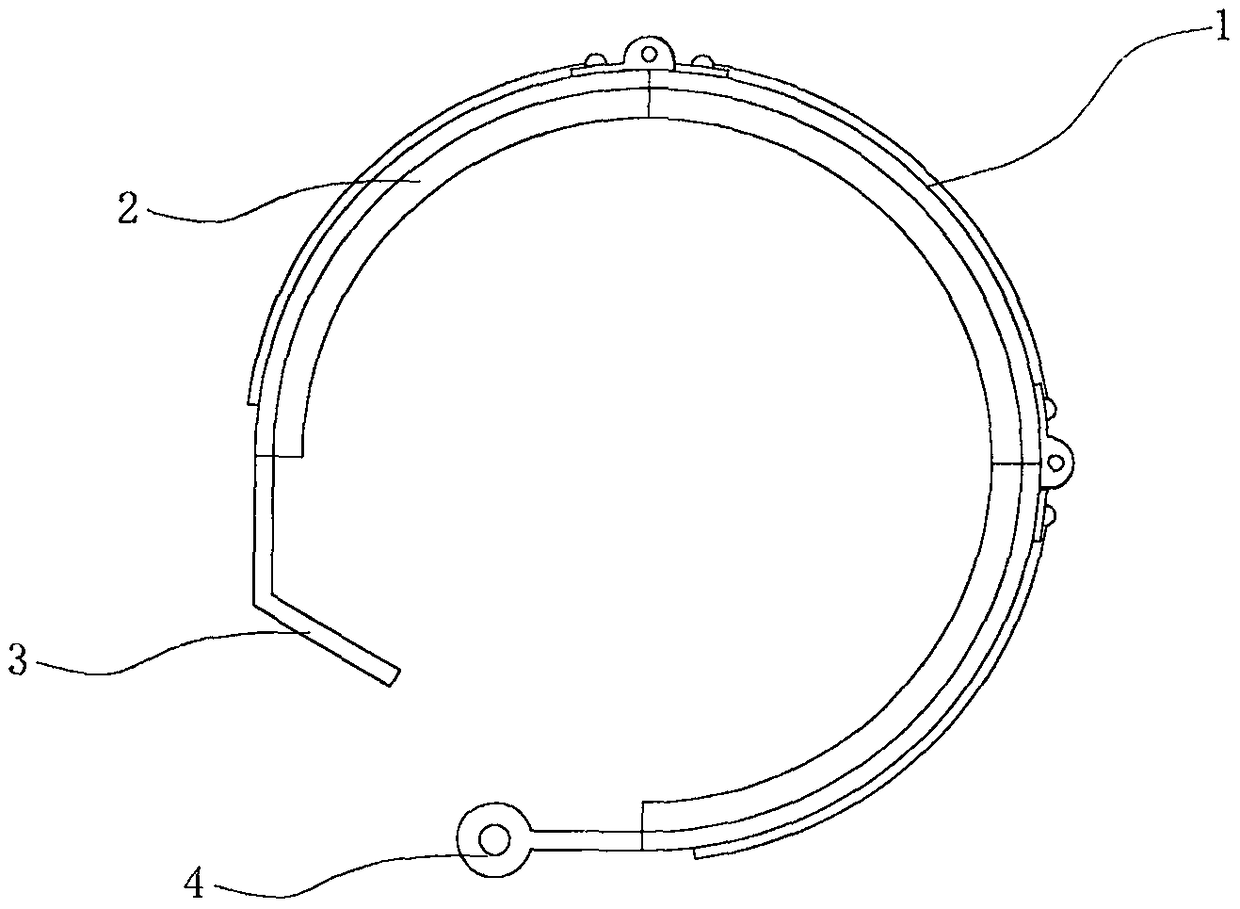

[0012] like Figure 1~2 As shown, the brake band used for the deceleration clutch in this embodiment includes a steel band 1, a friction band 2, a fixed plate 3 and a pin joint 4, the friction band 2 is bonded to the steel band 1, the fixed plate 3 and the pin The shaft joints 4 are respectively connected to the two ends of the steel belt 1. The steel belt 1 includes three sections of steel belt 11, and the three sections of steel belt 11 are connected together by hinges 12 and rivets 13. The friction belt 2 includes three sections corresponding to the sub-steel belts. The sub-friction belt 21, in addition, a reinforcing rib 11 along the horizontal direction is arranged in the middle of the sub-steel belt 11 to increase the strength of the sub-steel belt 11.

[0013] The above is only the preferred embodiment of the present invention, it shou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com