Water cooling motor air leakage detection method

A technology of a water-cooled motor and a detection method, which is applied in the direction of detecting the appearance of fluid at the leak point and using liquid/vacuum degree for liquid tightness measurement, etc., can solve the uneven sealing performance, affect the efficiency of use experience, and increase the cost. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

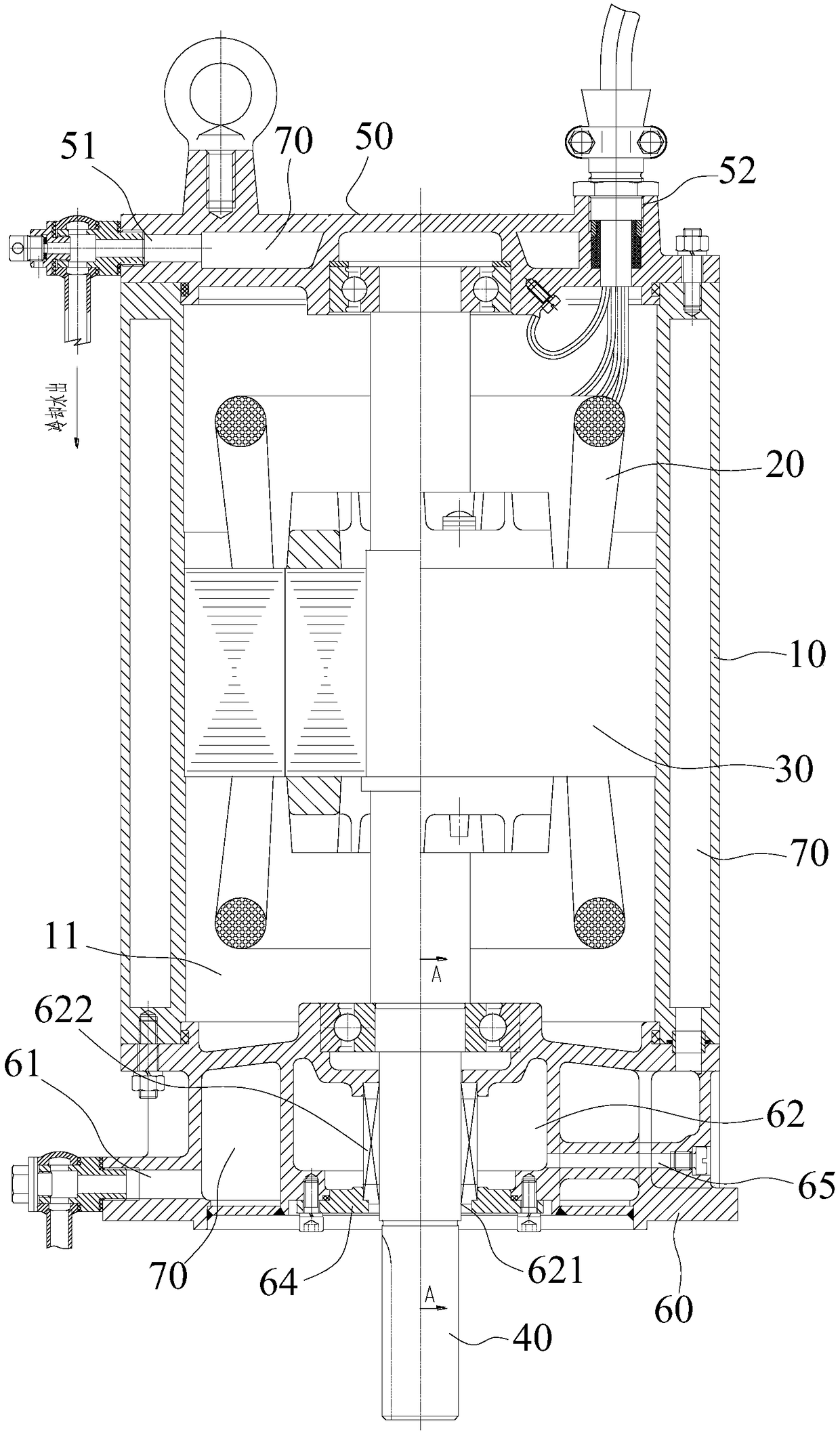

[0028] Such as Figure 1~3 As shown, in order to ensure that the water-cooled motor meets the sealing performance required for use when it is put into use, the present invention provides a method for detecting air leakage of the water-cooled motor. Investigate and deal with problems before it is put into use and immediately troubleshoot, reduce the rework and refurbishment probability of water-cooled motors, reduce maintenance costs and improve use efficiency.

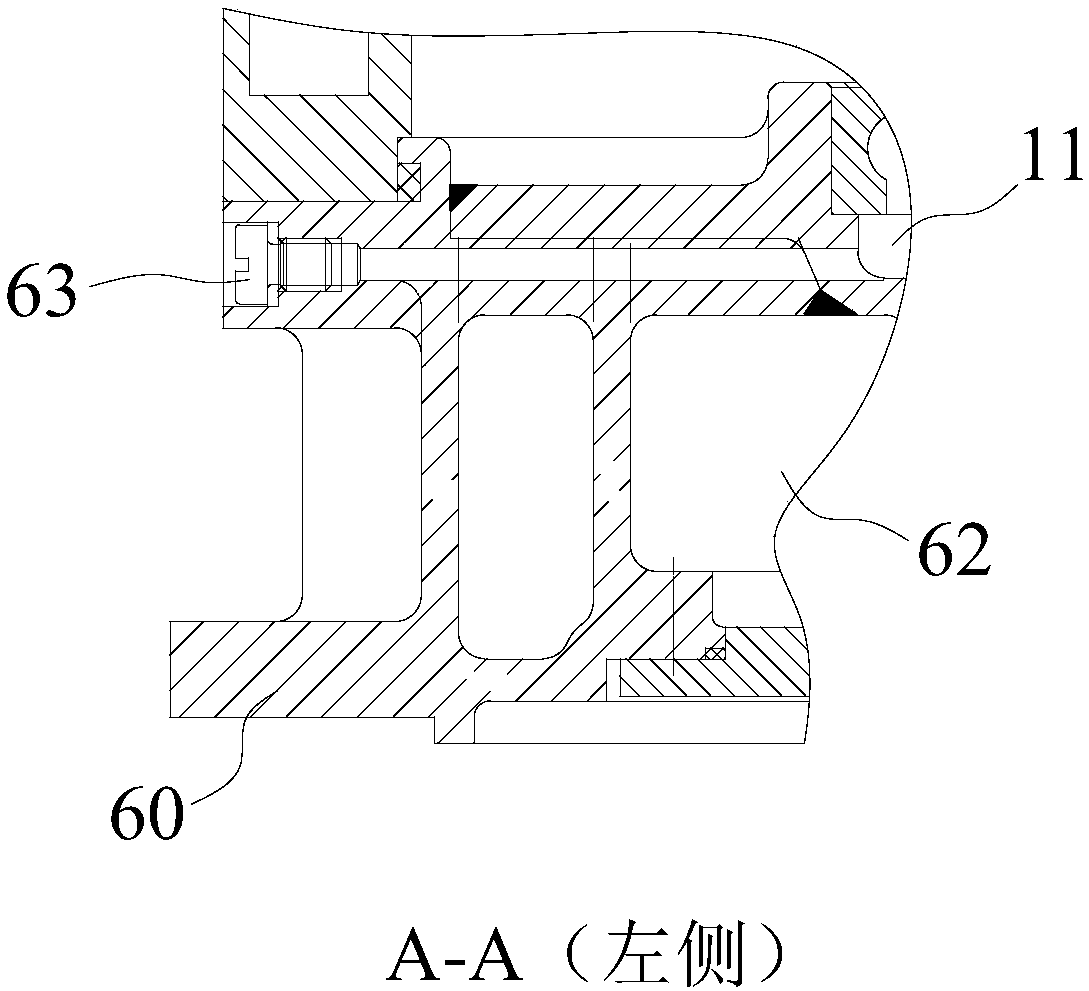

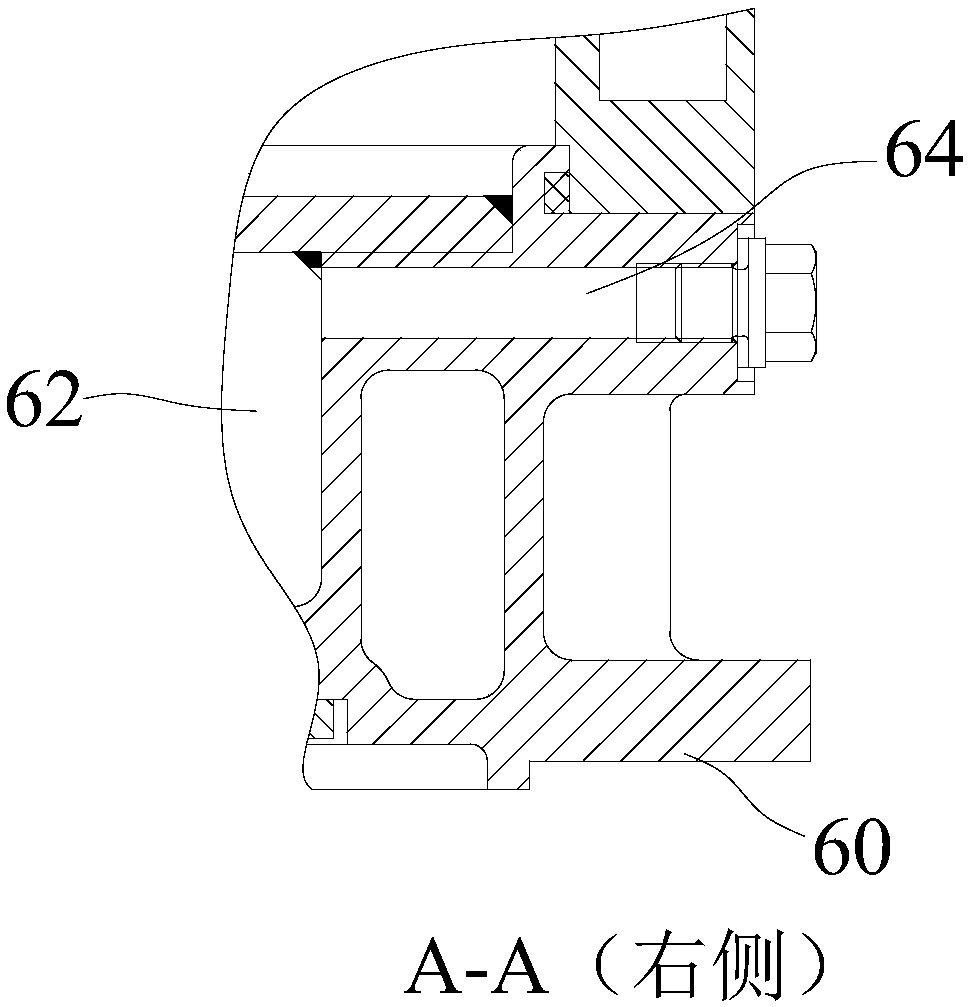

[0029] In order to fully explain the air leakage detection method of the water-cooled motor, this example provides a structure of a water-cooled motor, including: a housing 10, a stator 20 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com