Thermal zinc spraying drawing force detection method of wind turbine bearing

A detection method and technology of pulling force, which are applied in the application of stable tension/pressure to test the strength of materials, measuring devices, and preparation of samples for testing, etc. The problem of true and effective product surface bonding force can not be achieved, and the effect of true and effective data and high accuracy can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

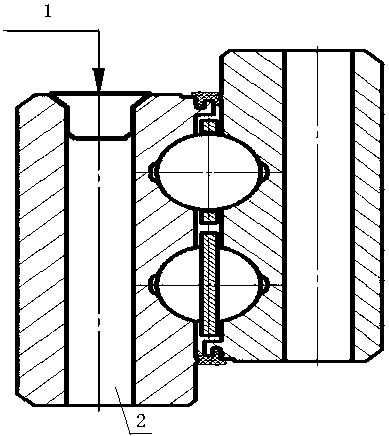

[0017] A method for detecting the drawing force of a wind power bearing by hot-spraying zinc, comprising the following steps:

[0018] Step 1: Make a pullout test sample block of the same material as the wind power bearing and with chamfers, the shape of the test sample matches the wind power bearing installation hole, and the diameter of the pullout force test sample is slightly smaller than the diameter of the wind power bearing installation hole;

[0019] Step 2: Install the drawing force detection sample block into the wind power bearing installation hole;

[0020] Step 3: The drawing force test sample block is sandblasted together with the wind power bearing;

[0021] Step 4: After sandblasting, the drawing force test sample block is sprayed with zinc along with the product;

[0022] Step 5: After spraying zinc, bond the rivets for the detection of the pull-out force to the sample block for the detection of the pull-out force;

[0023] Step 6: After waiting for 12 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com