An automatic crimping method

An automatic, indenter technology, used in instruments, measuring devices, electronic circuit testing, etc., can solve the problems of inaccurate automatic alignment and crimping, incomplete function realization, etc., to save labor costs, improve production efficiency, and improve accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

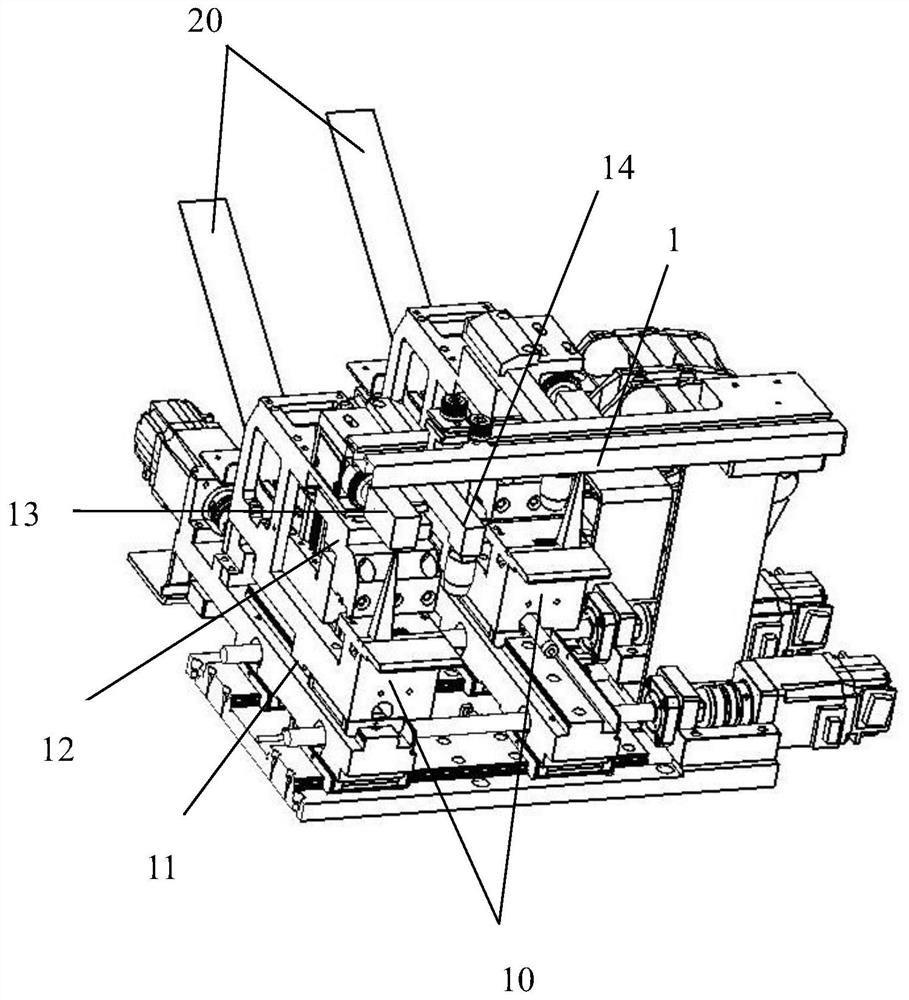

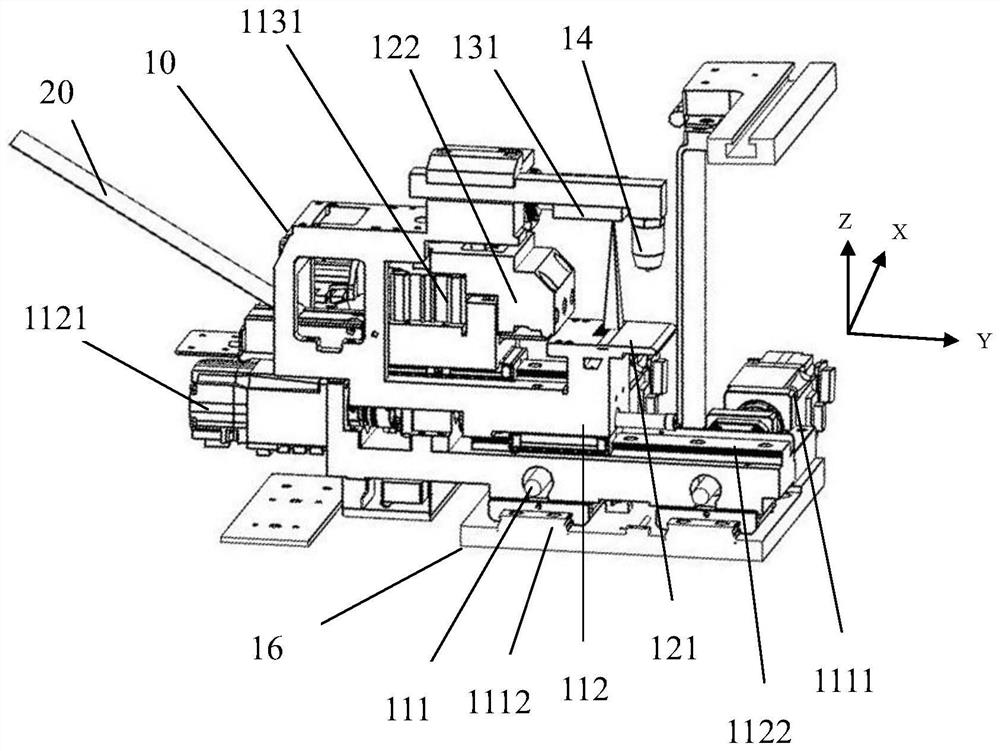

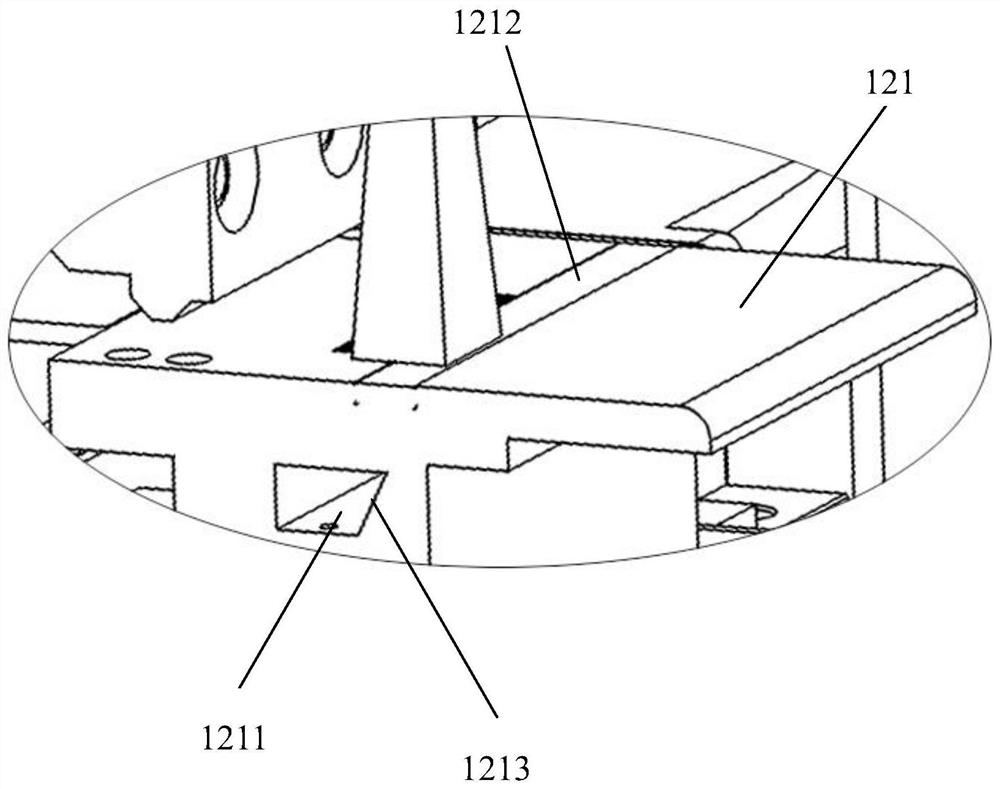

[0037] Such as figure 2 As shown, this embodiment provides an automatic crimping mechanism for panel point screen detection, including a moving mechanism 11, an indenter module 12 and an image system 13; the indenter module 12 is fixed on the moving mechanism 11 Above, as the moving mechanism 11 moves, the imaging system 13 is arranged above the indenter module 12, and the indenter module 12 and the imaging system 13 can move with the moving mechanism 11; The image system 13 obtains the relative position of the indenter 122 of the indenter module 12 and the panel test pad through the camera 131, and the indenter module 12 is used to connect the flexible circuit board 20 connecting the test signal to the panel The test pad is crimped.

[0038] The flexible circuit board 20 is driven to move by the moving mechanism. At the same time, the image system is used to collect and judge whether the positions of the test pad and the flexible circuit board 20 are aligned in real time. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com