Force control-based robot polishing trajectory estimation method

A technology of robots and robot arms, applied in the direction of program control, computer control, general control system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

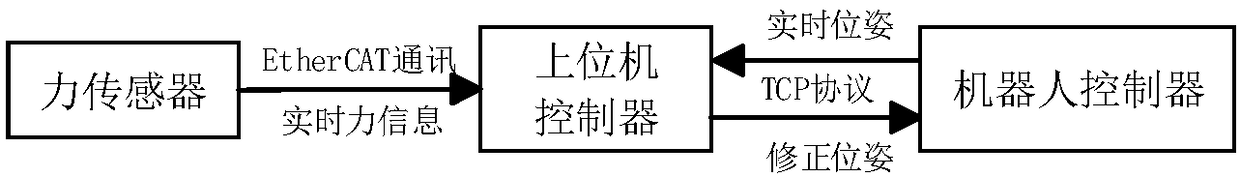

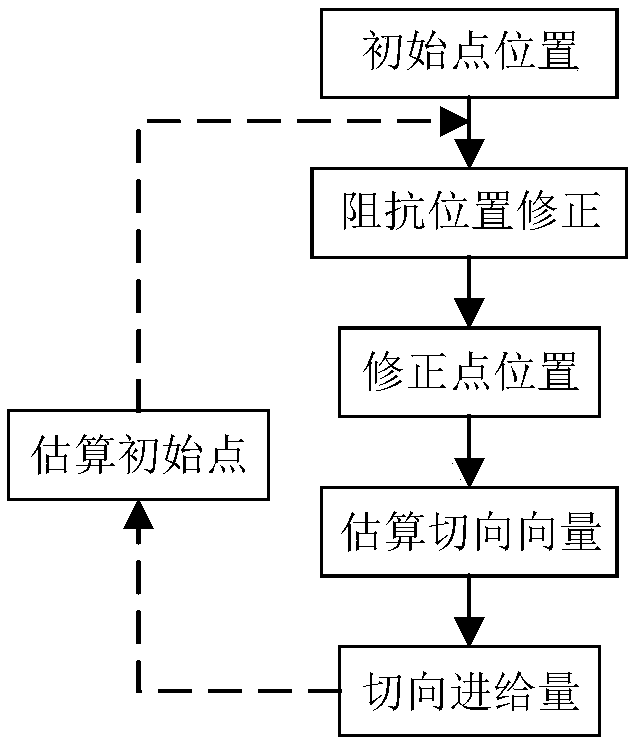

[0018] Such as figure 1 , the force sensor is used to collect the pressure between the grinding tool held by the robot grinding arm and the workpiece. The movement of the robot is controlled by the robot controller. The robot controller communicates with the host computer controller. The control system adopts a centralized control method, and the host computer controls The force sensor is connected to the force sensor to receive real-time force information; the robot controller, as a lower computer, sends real-time pose information to the upper computer controller, receives the pose information to modify the current trajectory, and controls the robot to perform grinding. The host computer controller corrects the position correction in the normal direction through force control according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com