Slitting mechanism

A technology of reset mechanism and cutting knife, which is applied in the direction of grain processing, etc., can solve the problems of time-consuming and laborious, and achieve the effect of safe and reliable operation, simple structure and good cutting conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0015] Example one

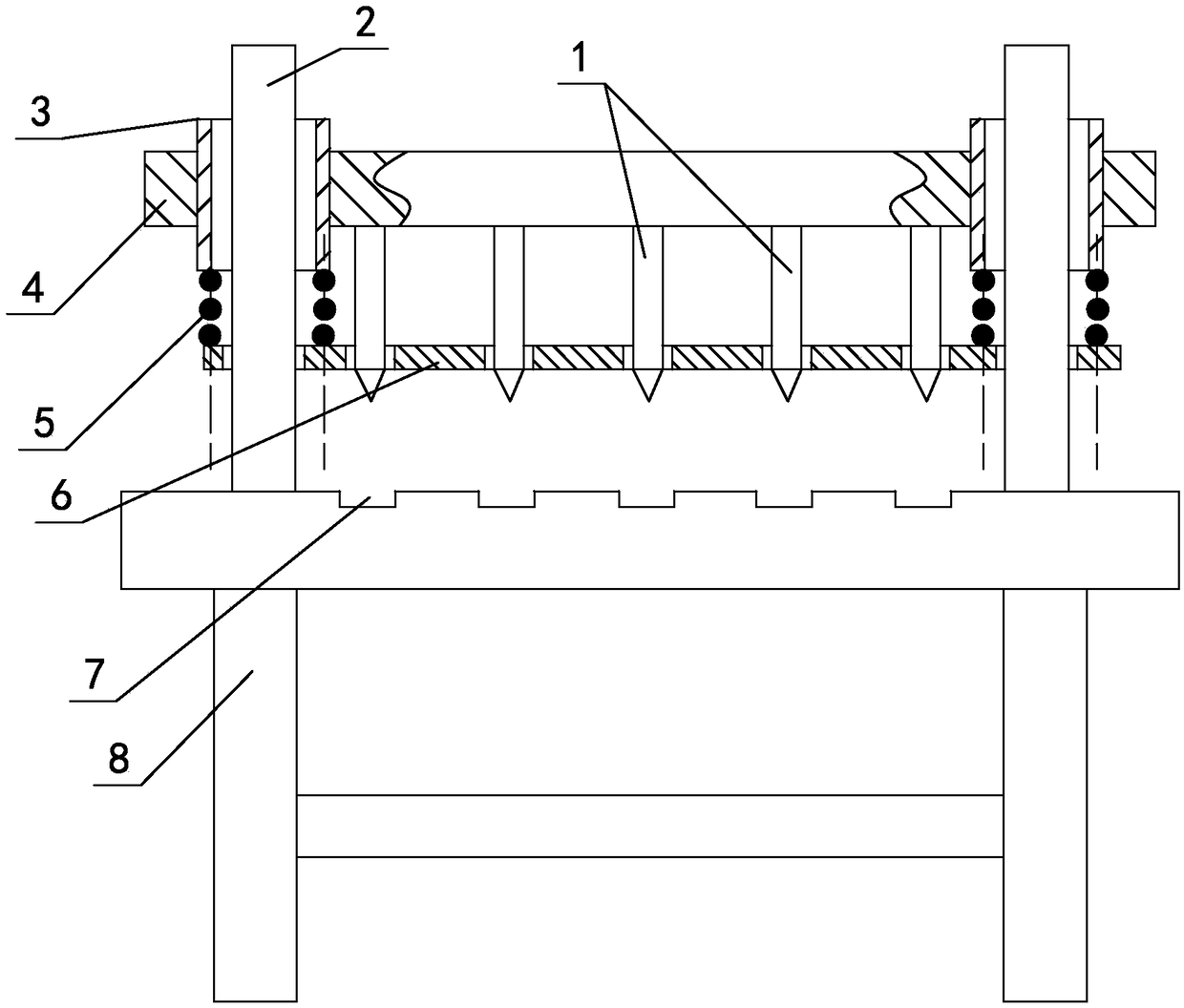

[0016] Such as figure 1 As shown, the slitting mechanism includes a worktable 8. Two guide rods 2 are provided on the worktable 8. The two guide rods 2 are arranged vertically and left and right in parallel, and the worktable 8 is horizontally arranged with up and down sliding Mounting plate 4, the two ends of the mounting plate 4 are respectively installed with guide sleeves 3 slidingly matched with the guide rods 2, and each guide rod 2 is installed in the guide sleeve 3, at the bottom of the mounting plate 4 between the two guide rods 2 At least two cutting knives 1 are installed, and a groove 7 for buffering is provided on the worktable 8 corresponding to the position where each cutting knives 1 cut.

[0017] In this embodiment, a stripping plate 6 is provided between the mounting plate 4 and the workbench 8. The left and right ends of the stripping plate 6 are provided with sliding holes that are slidably matched with the guide rods 2, and the guide rods ...

Example Embodiment

[0019] Example two

[0020] A change is made on the basis of the first embodiment, and the reset mechanism is changed into a rubber block, the upper surface of the rubber is bonded to the guide sleeve 3, and the lower surface of the rubber is bonded to the stripper 6.

[0021] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com