Machining method of turbine blade

A turbine blade cutting technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of high design cost, hindering chip falling, and adverse effects of turbine blade accessibility, etc., to achieve processing accuracy simple effect design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

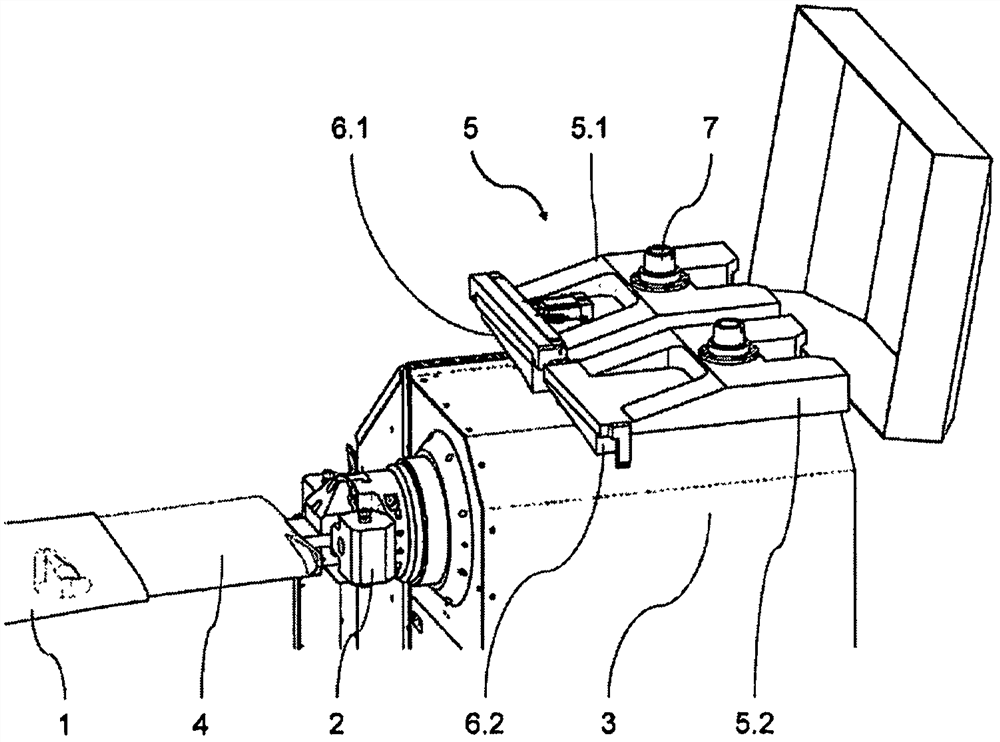

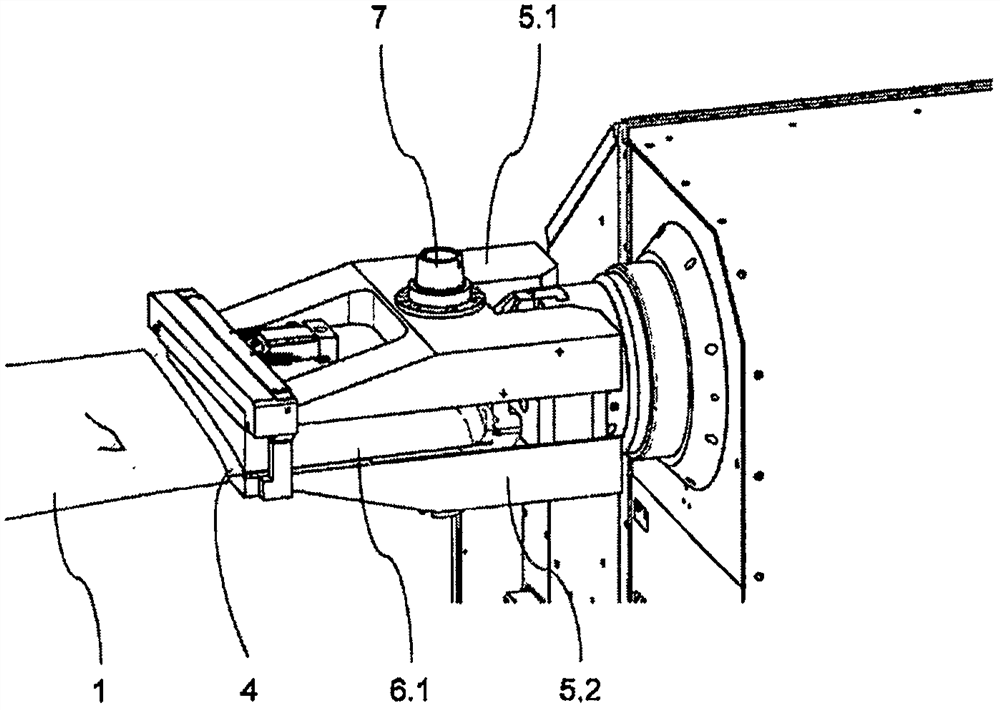

[0012] These two figures show in a perspective view the area of a machine tool during the machining of a turbine blade 1 with a rotatably driven blade tip clamping device 2 therein. The shaft and drive of the blade tip clamping device 2 are housed in the housing 3 . A blade root clamping device is provided, which is arranged opposite to the blade tip clamping device 2, and a tool shaft is provided which is at an angle to the longitudinal axis of the turbine blade 1, but not shown in the figure. figure 1 As shown in , the first profile section 4 adjacent to the blade tip has been machined by the tool. This machining is not necessarily finishing machining. It is only important that the profile section provides a defined, stable contact surface for the gripper jaws mentioned below.

[0013] An additional clamping device 5 consisting of two parts 5.1 and 5.2 for stabilizing the first profile section 4 is mounted on the housing 3, which is used in accordance with figure 1 Appl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com