Continuous curing device for grinding wheels

A technology of curing device and grinding wheel, which is applied in the direction of grinding device, metal processing equipment, grinding/polishing equipment, etc., and can solve problems such as rising heating temperature, low production efficiency, and grinding wheel defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

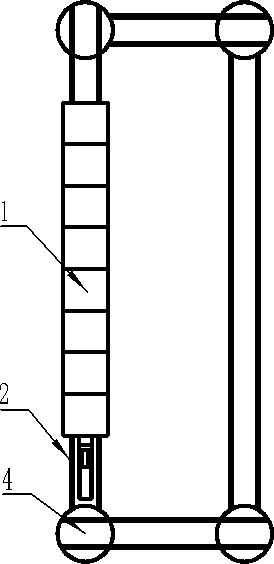

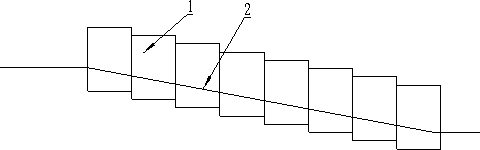

[0017] As shown in the figure, a row of parallel curing furnaces 1 are sequentially drilled through the side walls to form heating channels, and the installation heights of the curing furnaces 1 are successively lowered. The track 2 is arranged in a rectangular shape, with one side obliquely passing through the heating channel. The transport vehicles are arranged in sequence in the heating channel 1. After the new transport vehicle enters the entrance of the thermal channel 1, open the stopper at the exit section to complete the heating at the end. The transport vehicle is pushed out by the transport vehicle in front and then the stopper is closed. The transport vehicle enters the lifting turntable 4 when passing the corner of the track 2. The lifting turntable 4 can be rotated by 90° and installed on the hydraulic lifting device to lift, so that the lifting turntable 4 The upper rail is connected to the rail on the horizontal plane, so that the transport vehicle enters the tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com