Novel automatic buffer table for finished tobacco rods

A buffer table and tobacco rod technology, applied in the field of buffer tables, can solve problems such as damage, affecting product quality, and affecting the cleanliness of the production site, and achieve the effects of reducing labor intensity, simple structural design, and reliable working principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

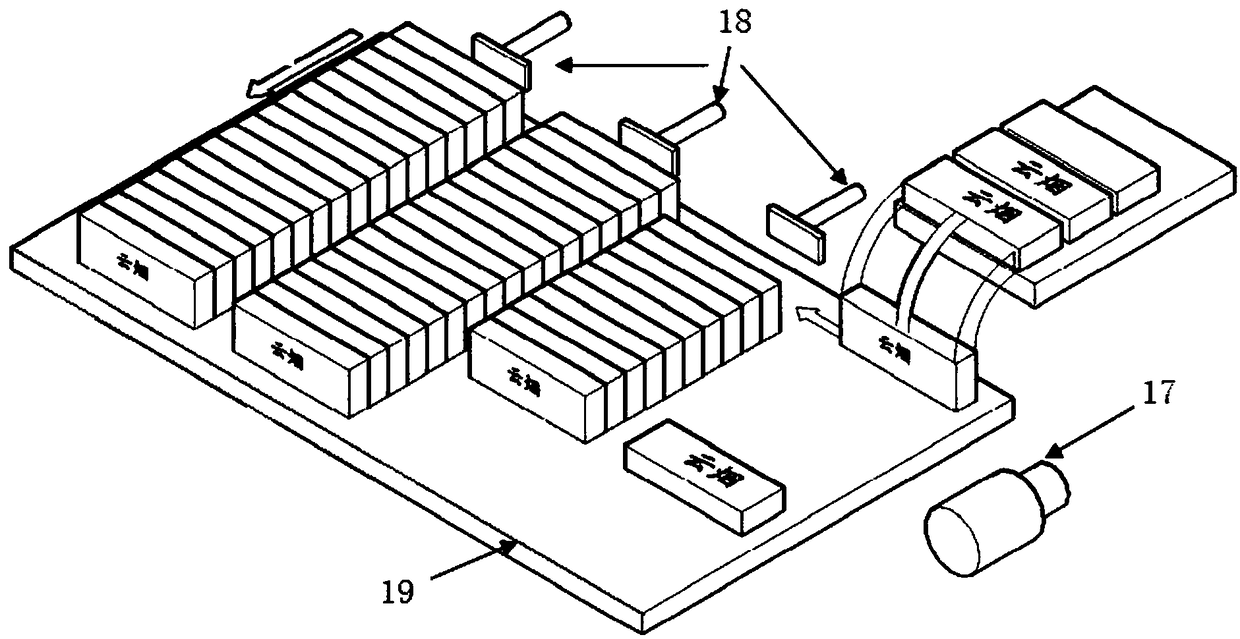

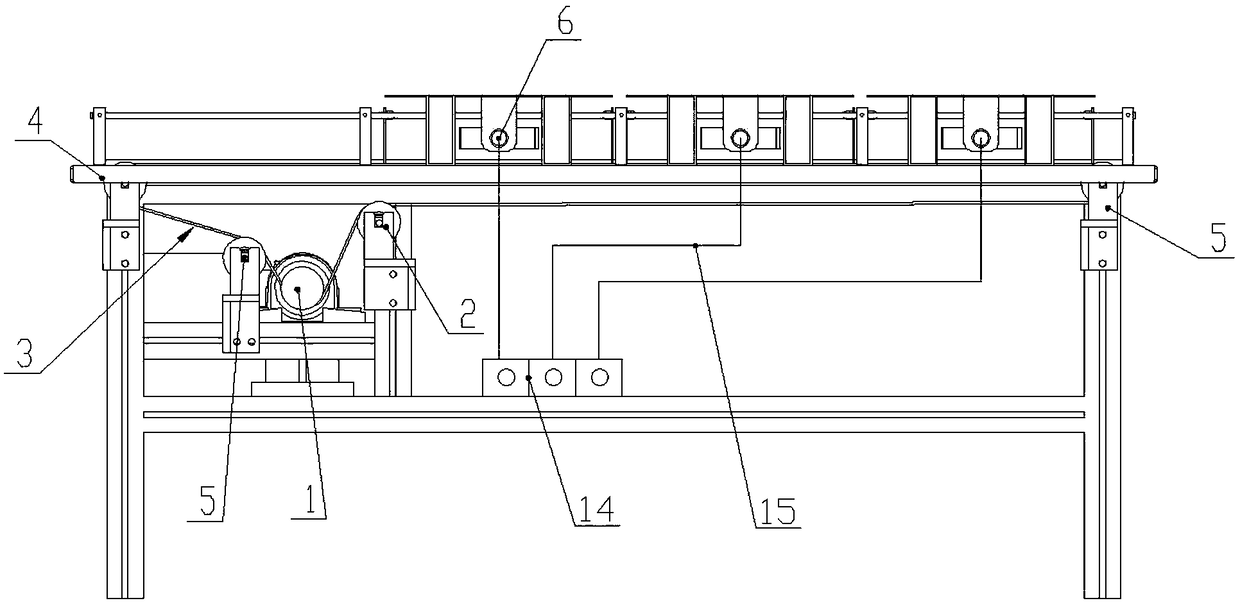

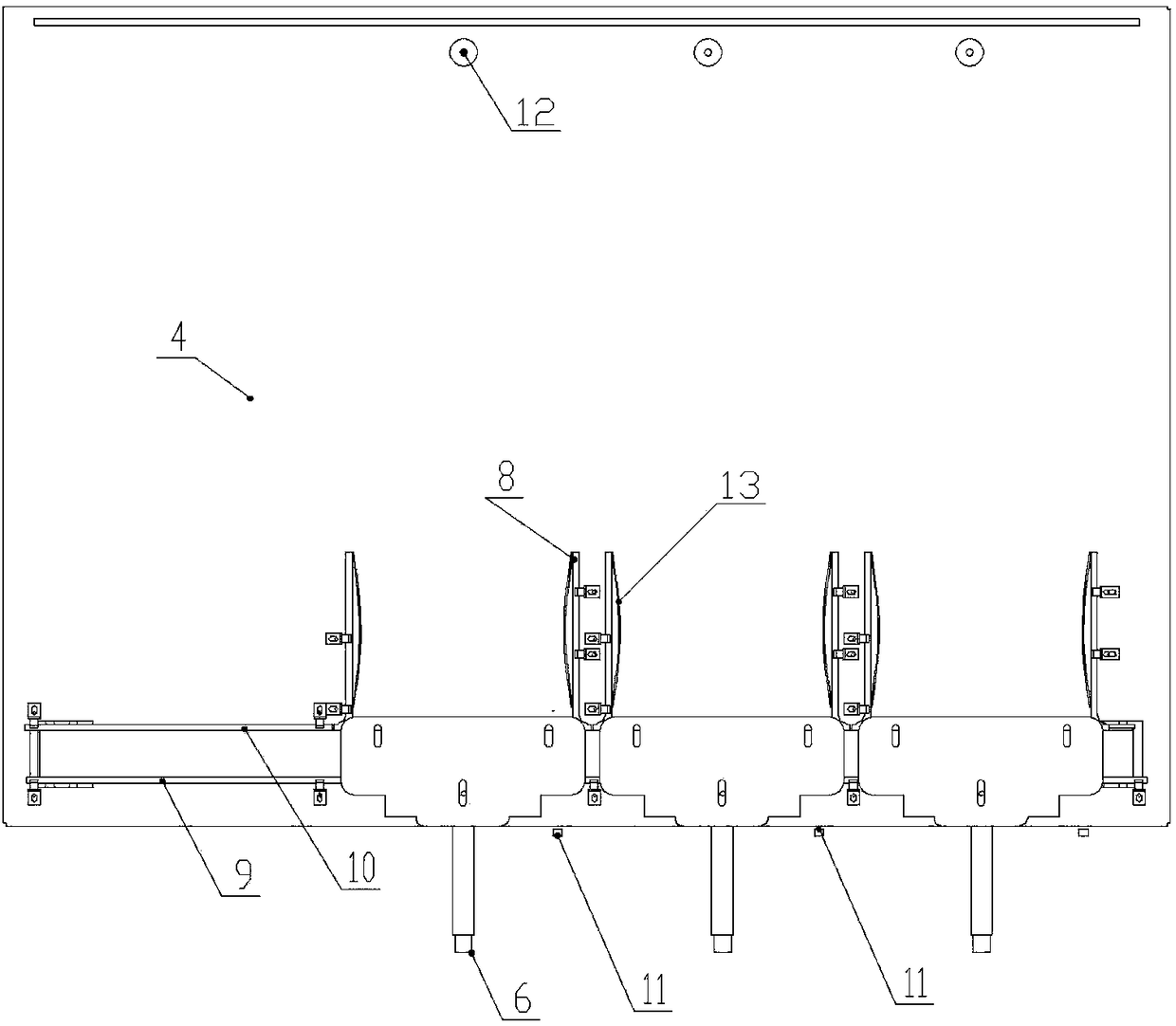

[0021] Embodiment one: if Figure 1-2 As shown, a new automatic storage table for finished tobacco rods includes a PLC controller 16, a tobacco rod conveying device 17, a push rod stacking device 18 and a tobacco rod stacking storage table 19, and the tobacco rod conveying device 17 includes a motor drive assembly 1. Tension wheel 2. Tobacco rod conveying belt 3. Table 4. Roller assembly 5. Such as image 3 As shown, the passage of the tobacco rod conveying belt 3 is provided with a tobacco rod finishing push rod 6, and there are three groups of the tobacco rod finishing push rod 6, and a protective fence 8 is provided in the pushing direction of the finishing push rod to ensure that the tobacco rod is pushed out. Not skewed. The two sides of the conveying belt for tobacco rods are provided with conveying guardrails, and the conveying guardrails are rear guardrails 9 and front guardrails 10 to ensure that the finished tobacco rods do not fall from the belt. The rod is in pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com