Stainless steel cleaner and preparation method thereof

A cleaning agent and stainless steel technology, applied in the field of cleaning agent, can solve the problems of shortening the service life of equipment, poor cleaning effect, and accelerating the replacement cycle of equipment purchase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

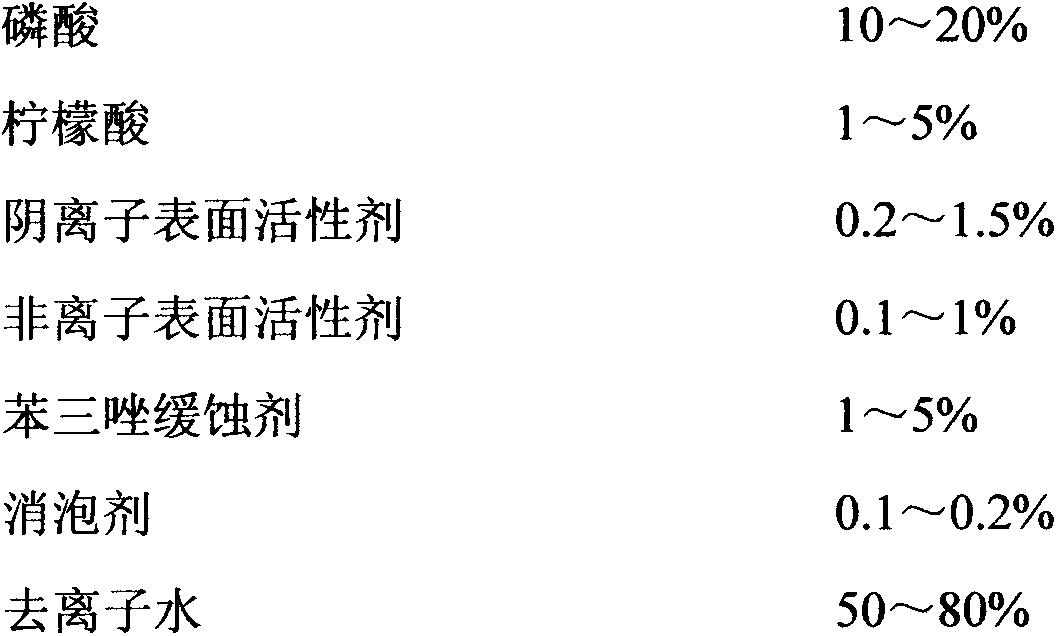

[0013] A cleaning agent for stainless steel, characterized in that: comprising the following components by weight ratio:

[0014]

[0015] The preparation method of described stainless steel cleaning agent, comprises the following steps:

[0016] Add deionized water to the mixer first, and slowly add phosphoric acid, citric acid, sodium dodecylbenzenesulfonate, fatty alcohol polyoxyethylene ether and benzotriazole corrosion inhibitor in sequence at low speed, and stir at room temperature until Uniform and transparent, then add defoamer and stir for 10 to 20 minutes.

Embodiment 2

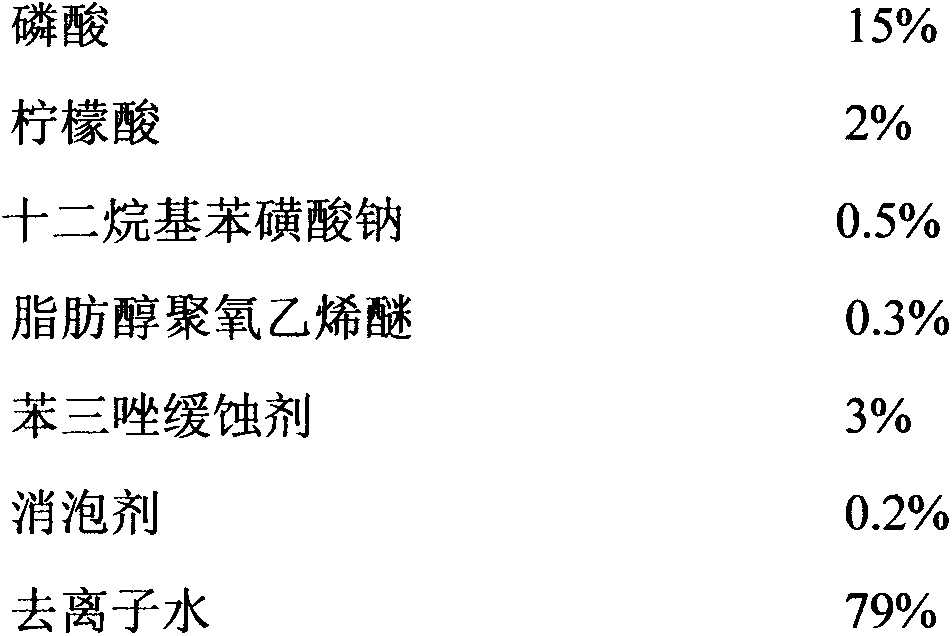

[0018] A cleaning agent for stainless steel, characterized in that: comprising the following components by weight ratio:

[0019]

[0020] The preparation method of described stainless steel cleaning agent is with embodiment 1.

Embodiment 3

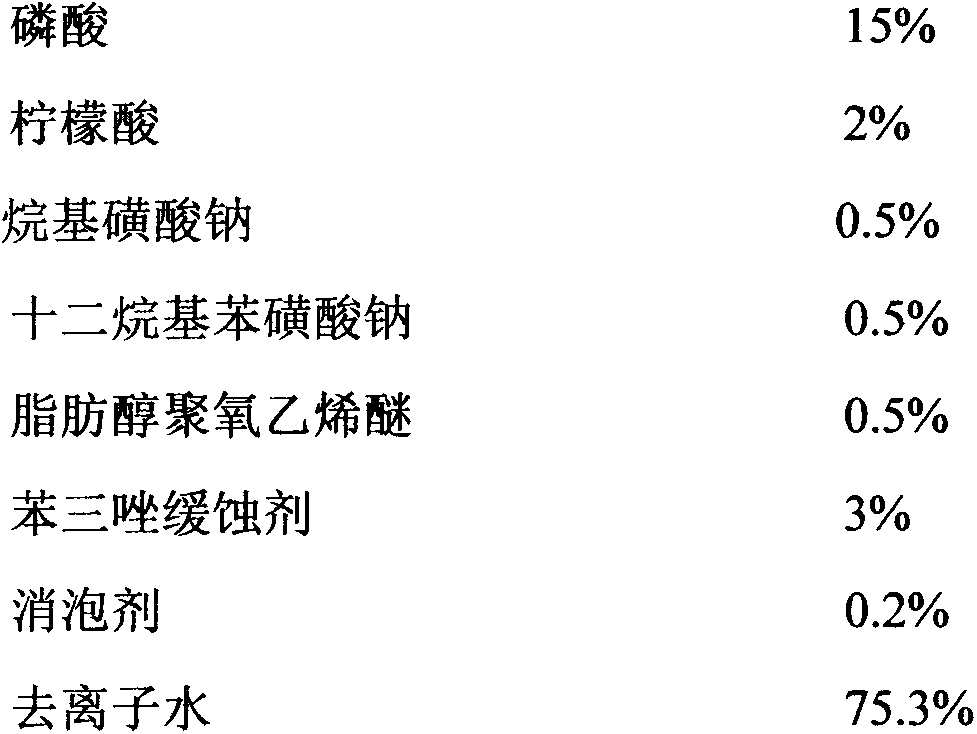

[0022] A cleaning agent for stainless steel, characterized in that: comprising the following components by weight ratio:

[0023]

[0024] The preparation method of described stainless steel cleaning agent is with embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap