A dry vacuum pump kit and test method for rotor performance test

A technology of dry vacuum pumps and rotors, which can be used in pump testing, liquid displacement machinery, machines/engines, etc., and can solve problems such as waste of materials and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

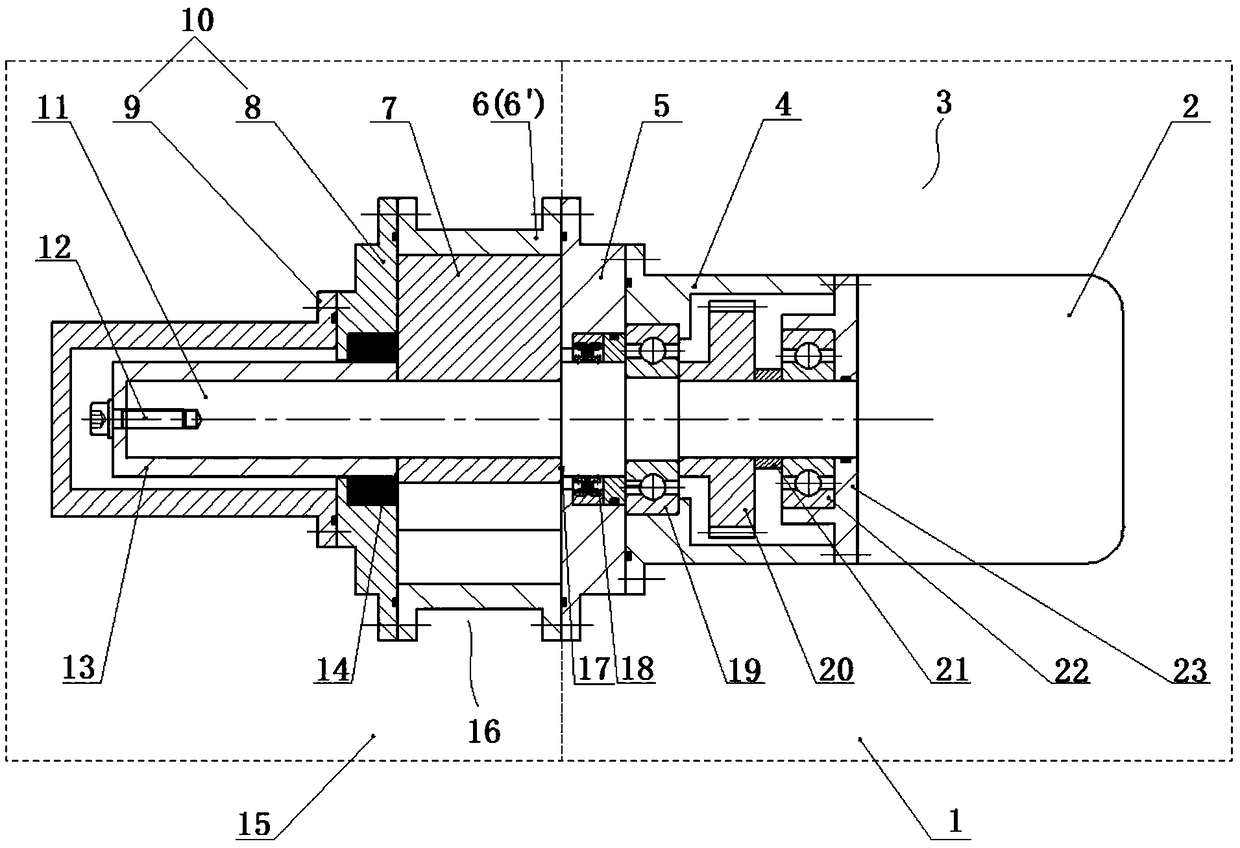

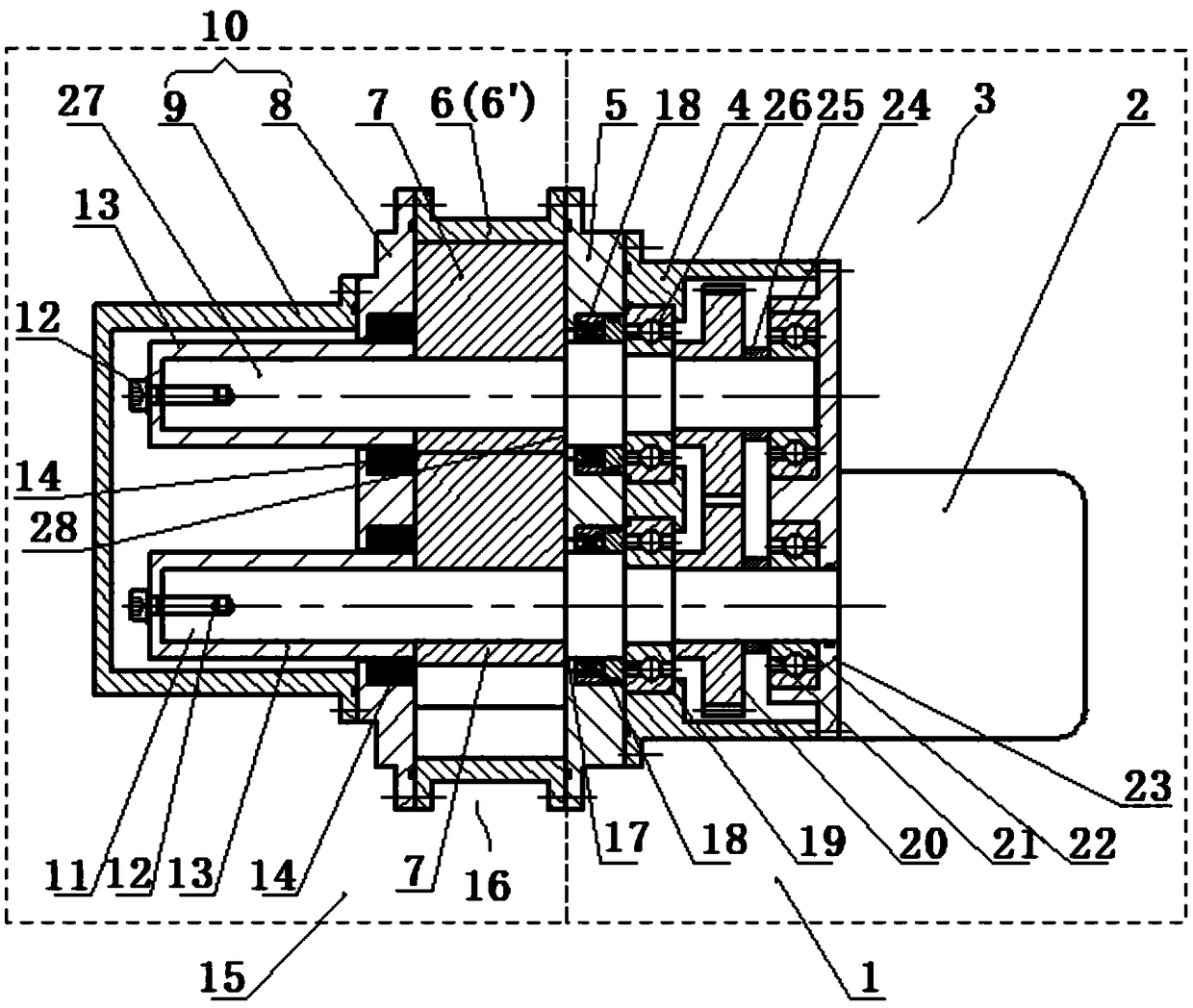

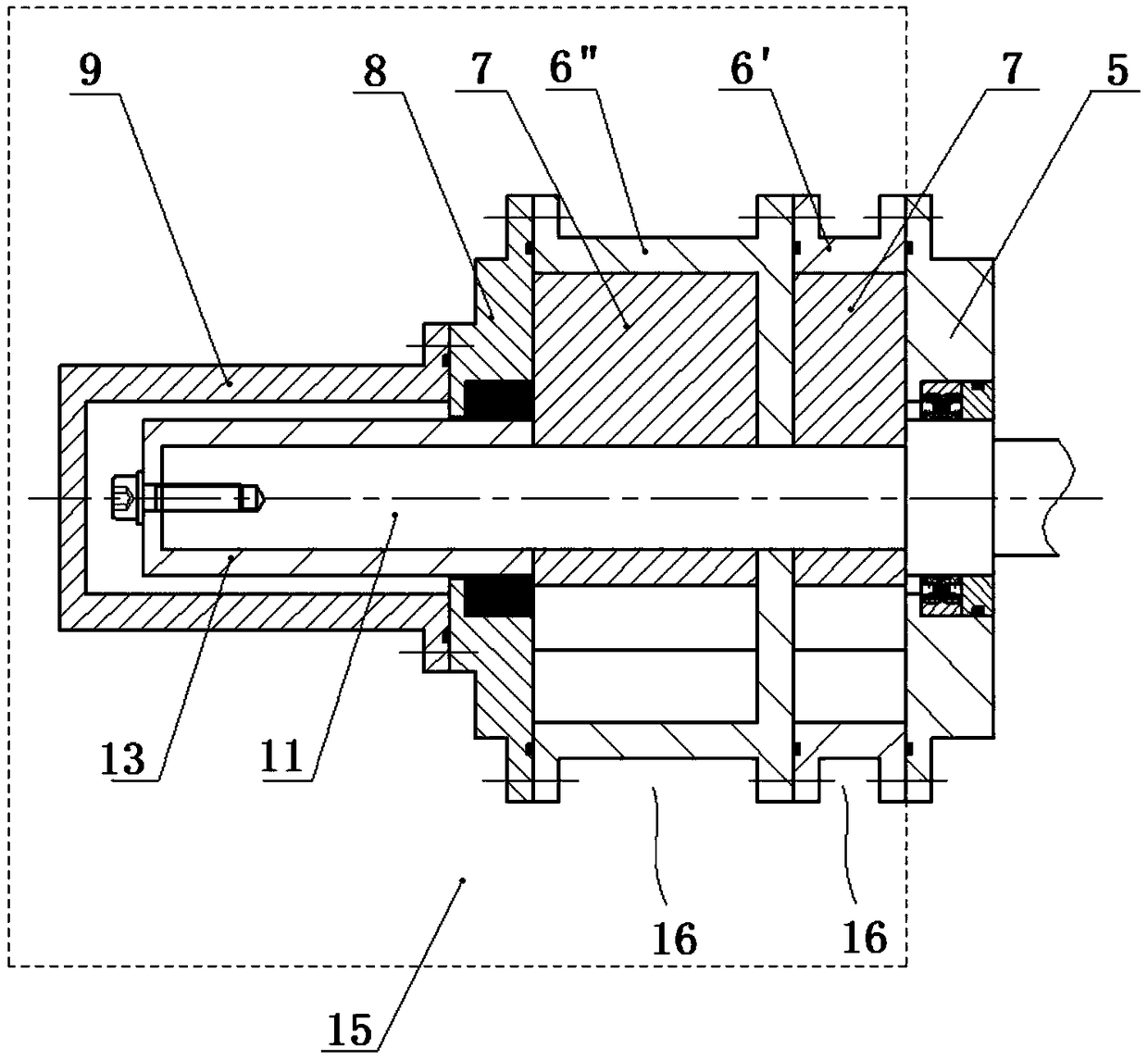

[0028] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0029]This embodiment provides a dry vacuum pump kit for rotor performance testing, which includes a fixed module 1 , outer covers 10 of various specifications, shaft sleeves 13 of various specifications, and stators 6 of various specifications. Outer covers 10 of various specifications, shaft sleeves 13 of various specifications and stators 6 of various specifications are selected according to the rotor / rotor combination to be tested, and the rotor / rotor combination to be tested and the selected outer cover 10, The shaft sleeve 13, the stator 6 and the fixed module 1 are installed together to form a dry vacuum pump, and then the dry vacuum pump can be tested, and then the rotor / rotor combination used in the dry vacuum pump can be tested for performance.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com