Three-phase brushless motor driving board

A technology of brushless motor and motor drive module, which is applied in the direction of electronic commutation motor control, single motor speed/torque control, electrical components, etc. Test conclusions and other issues, to achieve the effect of reducing R&D testing costs, high testing efficiency, and eliminating cumbersome operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

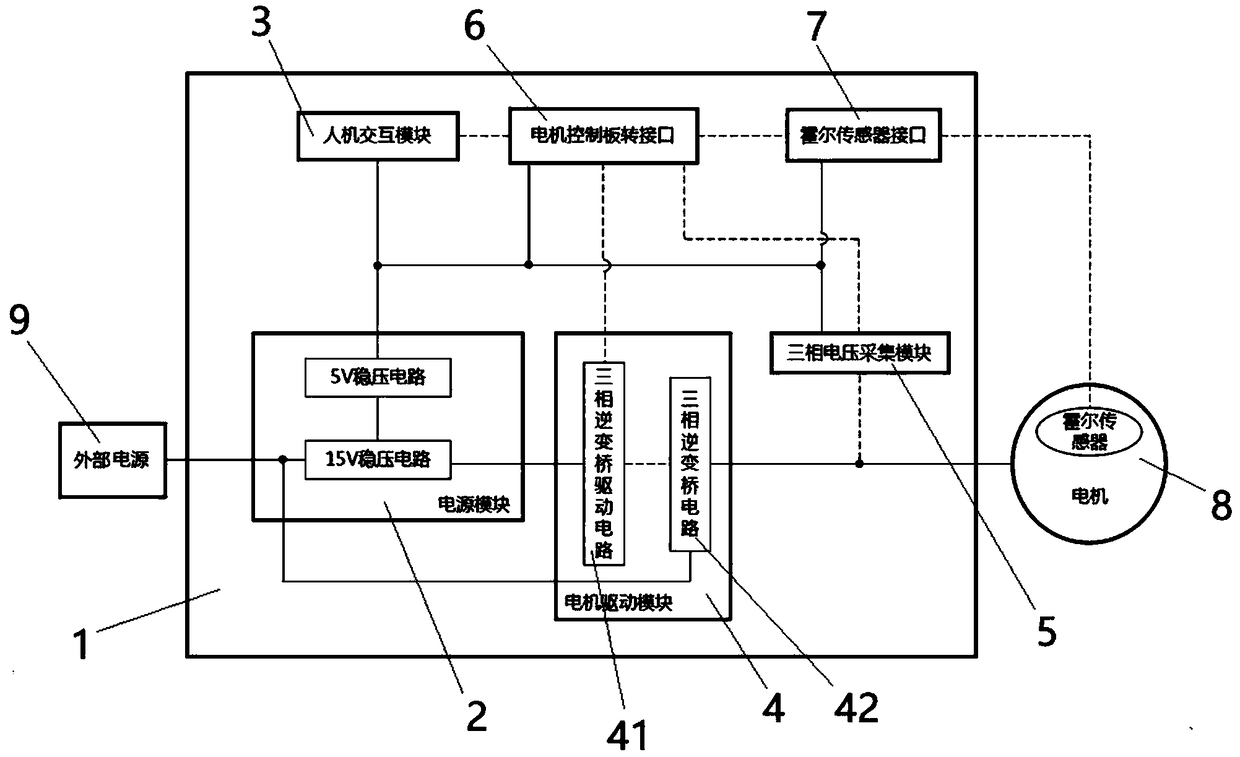

[0020] A three-phase brushless motor driver board, such as figure 1 As shown, it includes a substrate 1, on which a power supply module 2, a human-computer interaction module 3, a motor drive module 4, a three-phase voltage acquisition module 5, a motor control board transfer interface 6 and a Hall sensor transfer interface 7 are arranged;

[0021] The power module 2 includes a 5V voltage stabilizing circuit 21 and a 15V voltage stabilizing circuit 22. The power module 2 is used to connect the external power supply 9. The nominal voltage of the external power supply 9 is DC 24V. The 15V voltage stabilizing circuit 22 is used to input the external power supply 8. The 24V DC voltage is converted into 15V DC voltage, and the 5V voltage stabilizing circuit 21 is used to convert the 15V DC voltage converted by the 15V voltage stabilizing circuit 22 into 5V DC voltage. , the three-phase voltage acquisition module 5, the motor control board transfer interface 6 and the power input te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com