Vibration attenuation and pressure adjustment valve

A technology of pressure regulating valve and valve body, applied in the field of pressure regulating valve, can solve the problems of resonance, affecting the reliability and stability of product use, and greatly affecting the fatigue performance of pressure regulating valve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

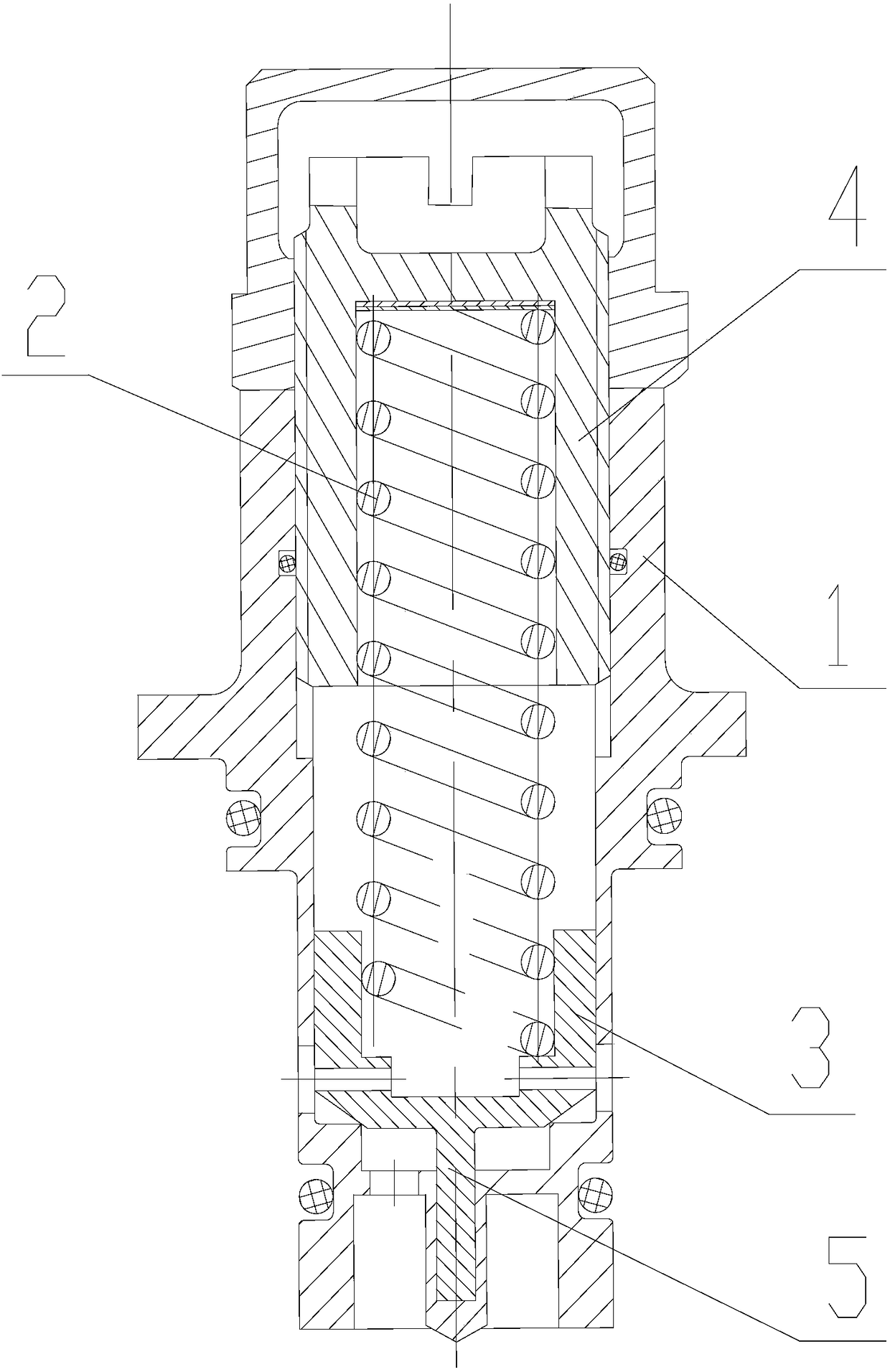

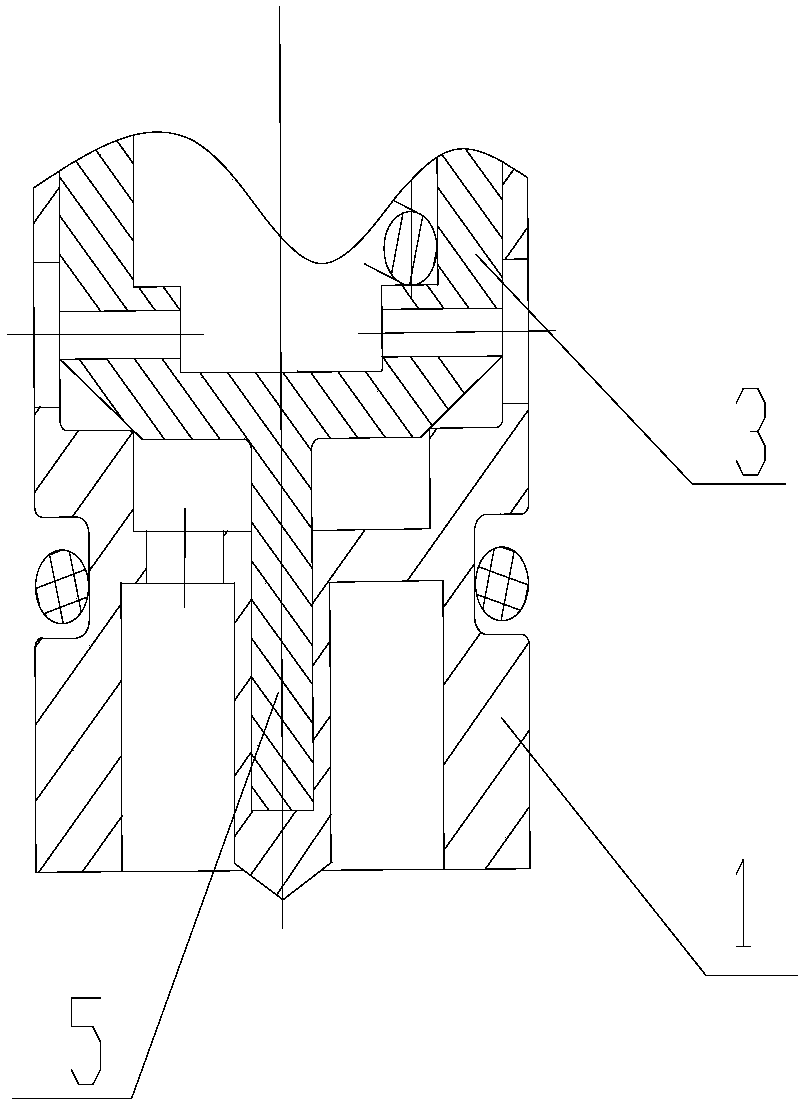

[0009] As shown in the figure, the vibration damping and pressure regulating valve includes a valve body 1, a valve 3, and a spring 2. The valve 3 is installed on the valve body 1, and the outer diameter of the valve 3 matches the inner diameter of the valve body 1; the spring 2 is arranged on the valve body. Inside the body 1, one end is pressed on the adjusting screw 4 installed on the valve body 1, and the other end is pressed on the valve 3. Under the action of the spring 2, the bottom of the valve 3 is made to lean against the steps inside the valve body 1; The valve body 1 is provided with an overflow hole at the position of the valve 3; the bottom of the valve 3 is provided with a cylinder 5 extending outward, and the valve body 1 is provided with an inner chamber, and the cylinder 5 is arranged in the inner chamber and match with the inner cavity gap.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com