Movable/rotatable/storable oil can

An oil pot, an integrated technology, applied in the field of kitchen utensils, can solve the problems of difficult to meet various needs, single and widespread use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

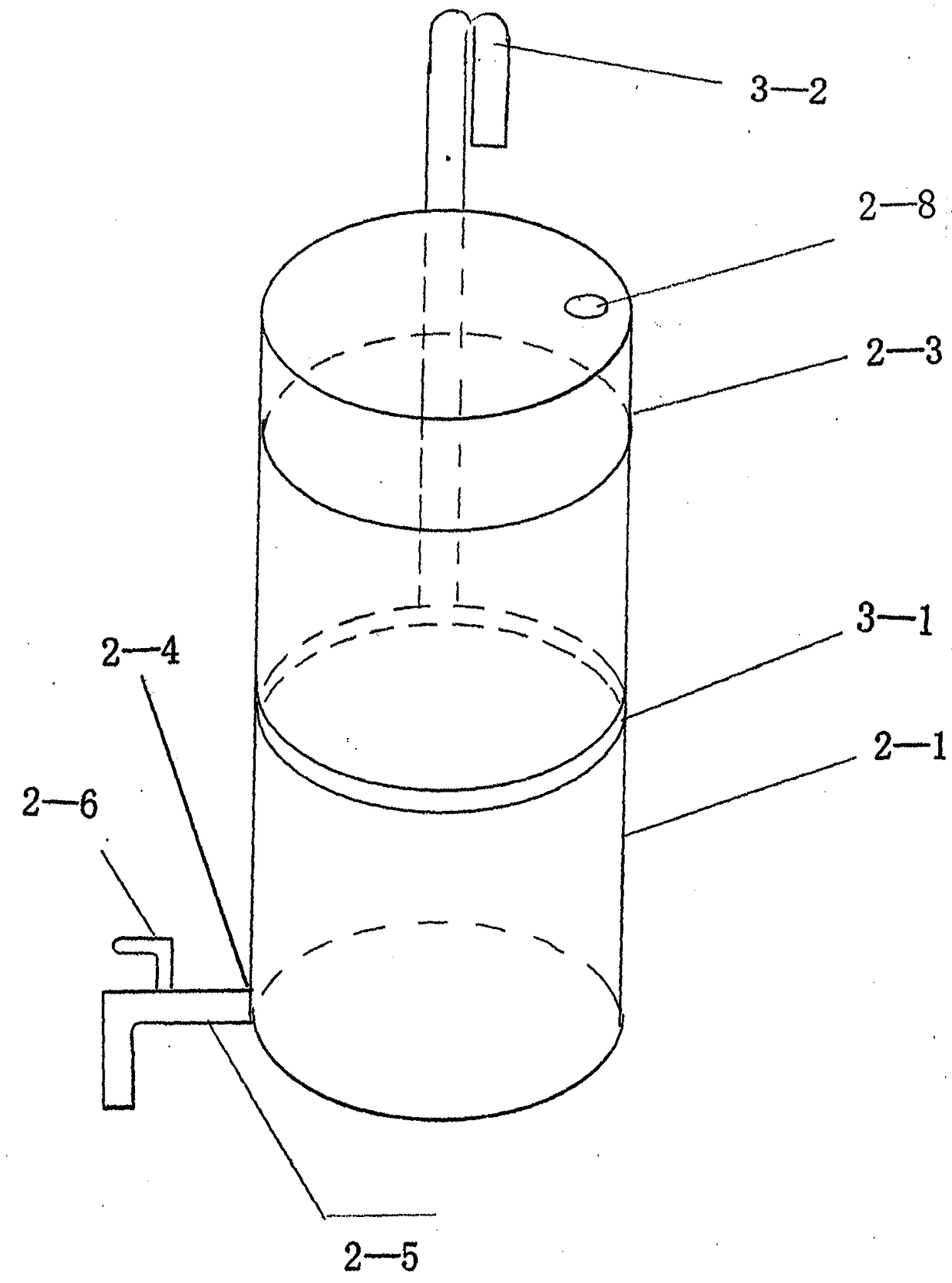

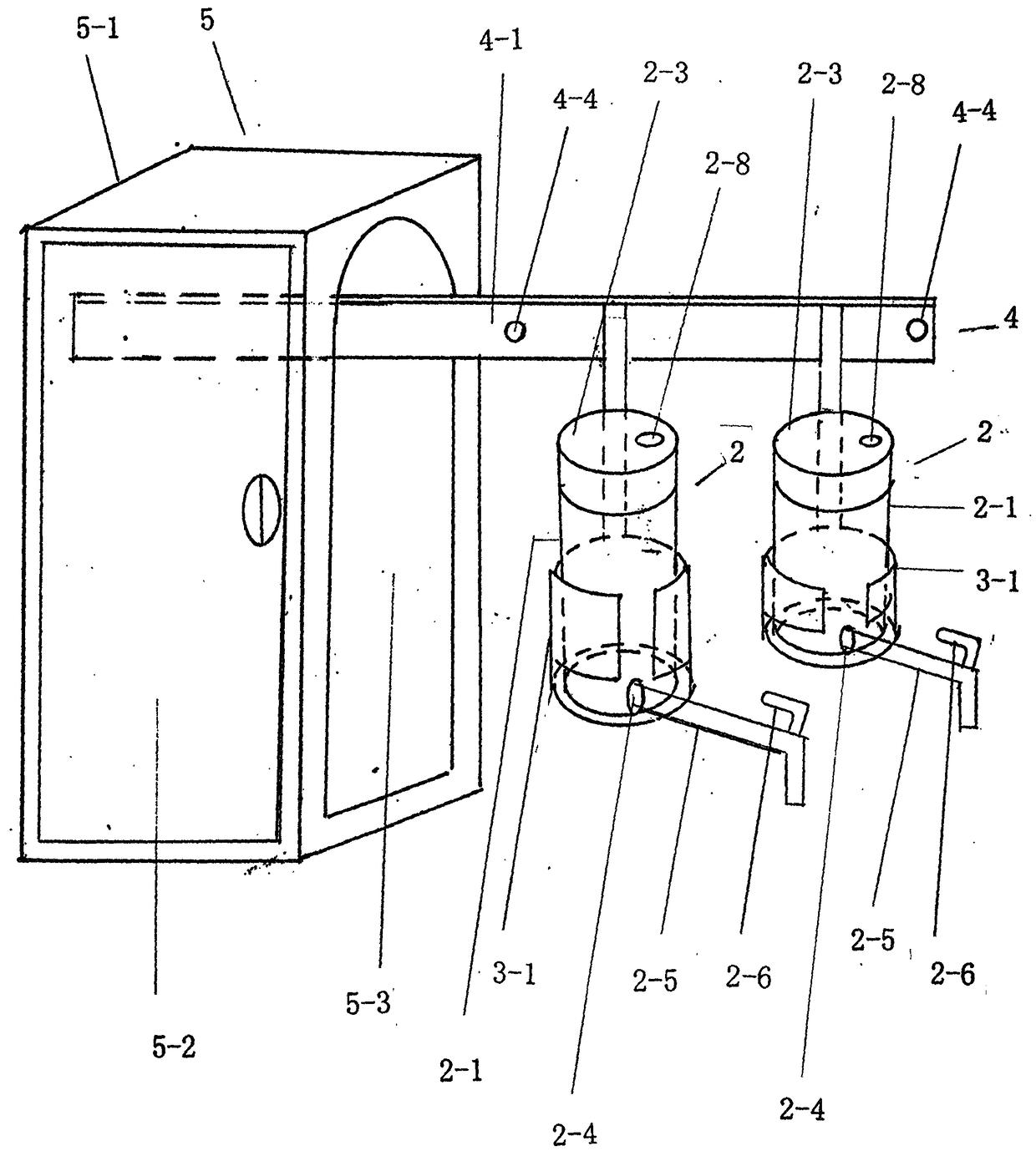

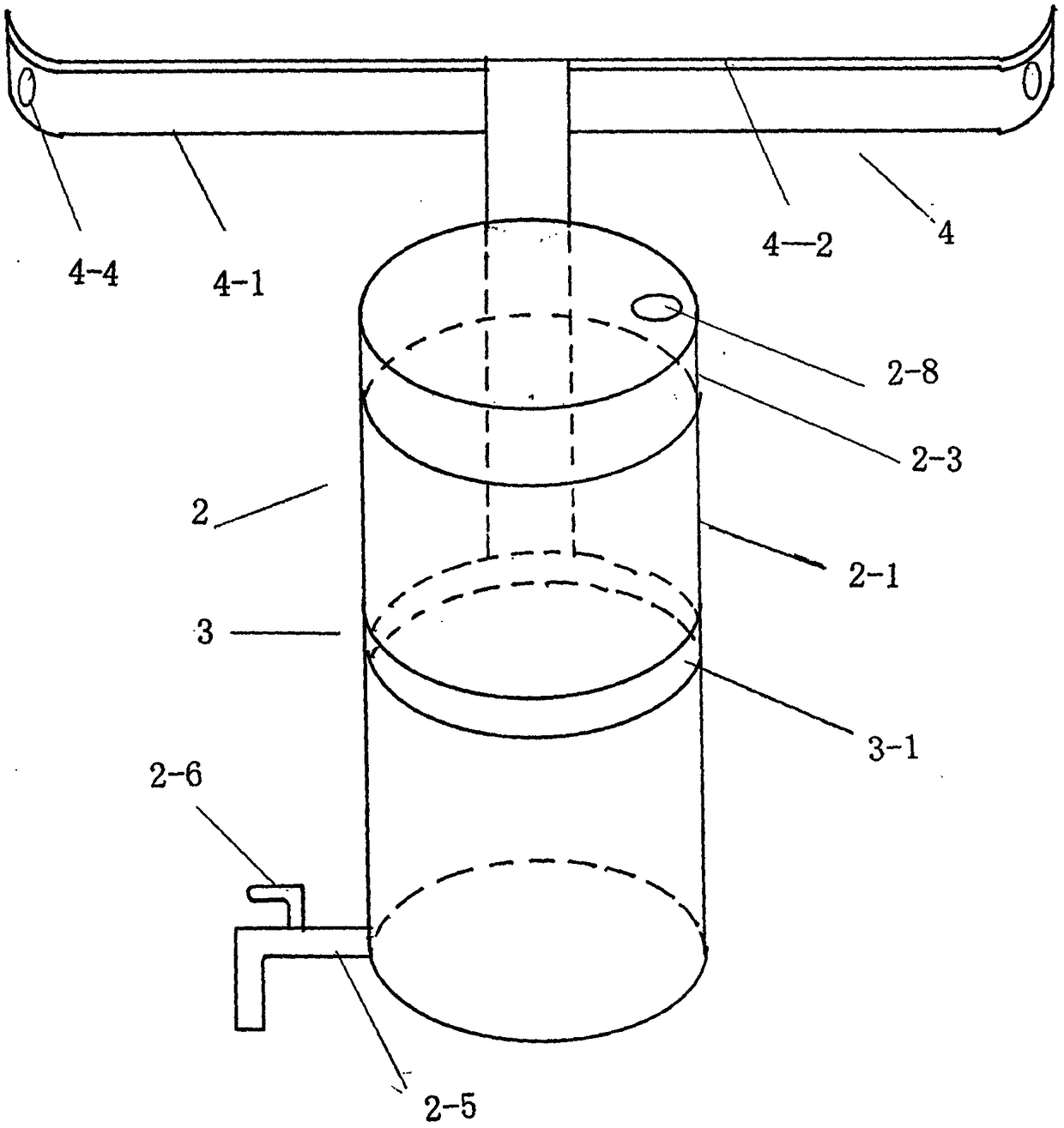

[0089]By adopting prior art, a track 4 is fixedly arranged on the wall above the cooking utensils used for cooking dishes and meals by two post track piles 4-3, four connecting devices 4-4 or fixed, moving object surface and connected with kettle cabinet 5 To connect, two oil pots 2, one large and one small, are connected with the track 4 under the load of corresponding two pot holders 3, one large and one small, and the two oil pots 2, one large and one small, are connected to the track 4 under the load of two pot holders 3, one large and one small. Under the load, the access to and out of the pot cabinet 5 is realized sequentially through the track 4, wherein, two oil pots 2, one large and one small, are equipped with an oil pot main body 2-1, a pot cover 2-3, an oil pipe docking port 2-4, and an oil pipe 2 -5, faucet 2-6, oil pot main body 2-1 upper end face spout 2-2, pot cover 2-3 upper end face air vent 2-8; two pot supports 3, one large and one small, are all provided wi...

Embodiment 2

[0093] By adopting the existing technology, a track 4, two track piles 4-3, four connecting devices 4-4 are connected and combined with the range hood body 6, wherein the track main body 4-1, the track pile 4- 3 and the exhaust (suction) range hood body 6 are initially set as one, to achieve fixed connection, or, according to the different needs of users, install and realize the track main body 4-1, track pile 4-3, and connecting device 4-4 Combination with the connection of the smoker (suction) range hood body 6, and then realize the suction (suction) range hood body 6 of at least one track 4, at least one pot holder 3, and at least one oil pot (see attached Figure 16 ).

Embodiment 3

[0095] By adopting the prior art, a track 4, two column track piles 4-3, four connection devices 4-4 are connected and combined with various stove bodies 7 such as gas stoves and electromagnetic stoves, wherein the track main body 4-1, the track The pile 4-3 is initially set as one with various stove bodies 7 such as gas stoves and electromagnetic stoves to realize a fixed connection, or it can be set according to the different needs of users and realize the track main body 4-1 and the track pile 4-3 , the connecting device 4-4 and various types of stove body 7 such as gas stoves, electromagnetic stoves, etc. Stove body 7 (see attached Figure 17 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com