Robot automatic welding method for special-shaped heavy plate

An automated welding and robot technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low efficiency of robot tracking and teaching technology, inability of production progress to meet production needs, and backward production process, so as to optimize production and production. process, reduced intervention time, increased productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

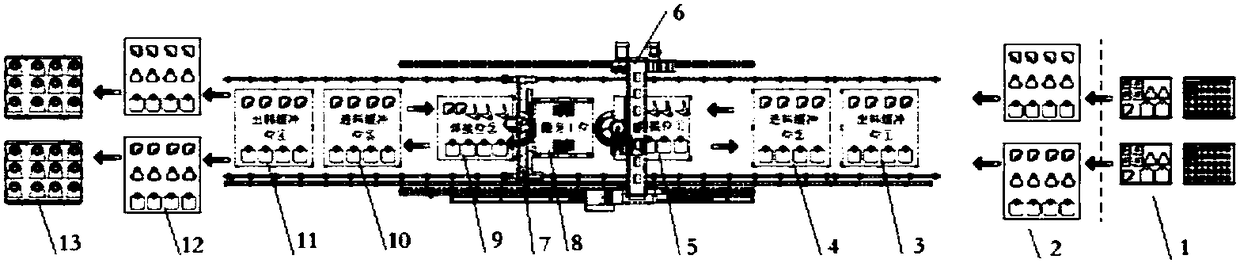

[0029] to combine figure 1 , special-shaped heavy board robot automatic welding workstation is mainly composed of eight parts:

[0030] CNC incoming material area 1: This station is specially set up with a transfer box for incoming heavy board components. After incoming materials, the component materials and transfer boxes can be placed directly in the designated area according to the position, without loading and unloading again and the transfer box reusable.

[0031] Lifting lug assembly area 2: Two assembly work platforms are set up in this area. There is a hanging basket tooling of the same size as the welding platform on the platform. The heavy plate components are assembled in the hanging basket. After the assembly is completed, the hanging basket is hoisted to the feed buffer area ② and the feeding buffer area ③, real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com