Automatic feeding machine and automatic feeding method thereof

An automatic feeding and machine tool technology, applied in metal processing and other directions, can solve the problems of low production efficiency and difficult automatic feeding equipment, and achieve the effect of improving processing efficiency, ingenious design and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing:

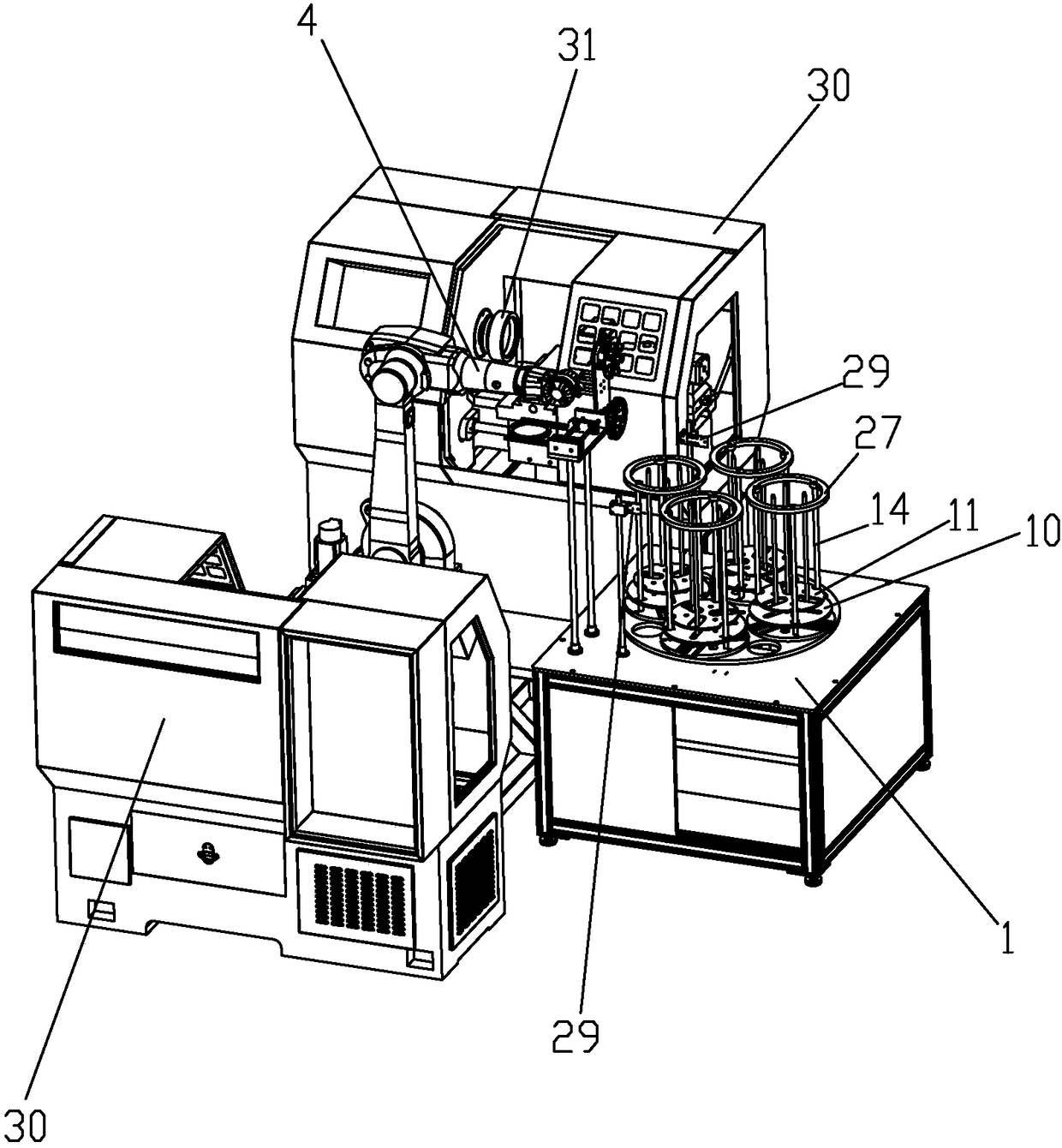

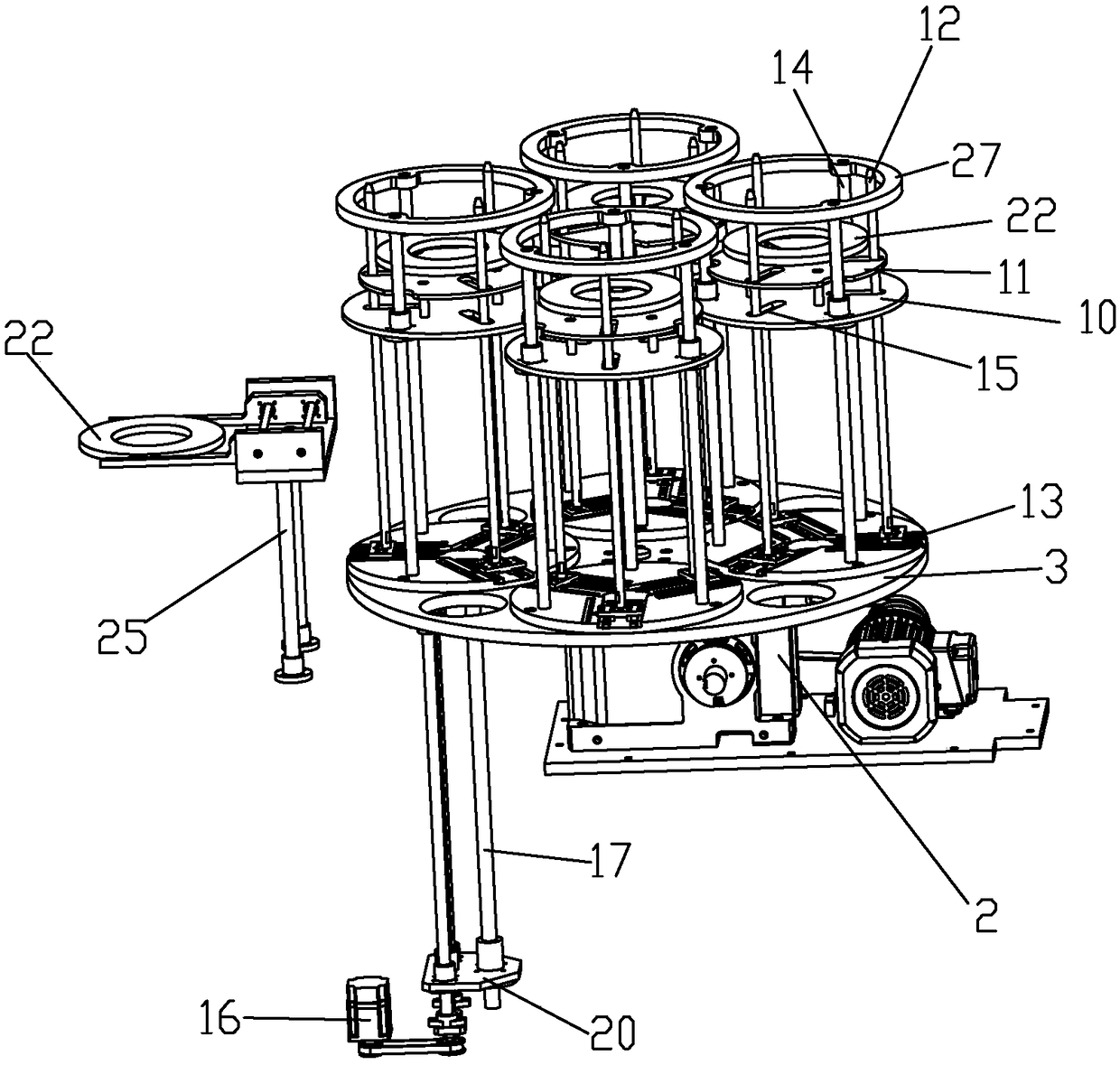

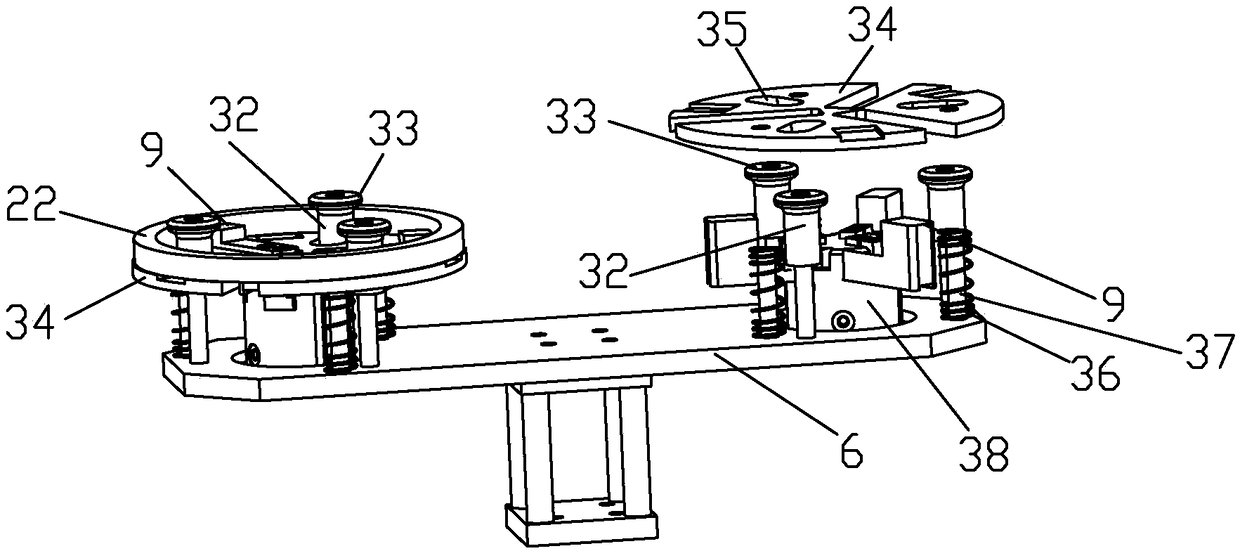

[0041] Such as Figure 1 to Figure 6As shown, a kind of automatic feeding machine comprises workbench 1, and described workbench 1 is provided with the turntable 3 that is driven to rotate by multi-station divider 2, is provided with a plurality of stations on turntable 3, each station Multiple layers of workpieces 22 can be stacked on the position, and each layer contains a workpiece 22. Below one of the workstations of the workbench 1, there is an ejection mechanism that can extend the turntable 3 to eject the workpieces 22 in sequence. It includes a manipulator 4 for grabbing the uppermost workpiece 22 of the station lifted by the ejector mechanism and placing it on the machine tool for processing, and a temporary placement table for placing the workpiece 22 for the manipulator 4 to grab the workpiece 22 from another direction 5.

[0042] There is only one ejector mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com