Component prefabricated mold

A mold and component technology, applied in the field of component prefabrication molds, can solve problems such as failure to meet bridge construction accuracy requirements, air bubbles, voids, uneven top surfaces of components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

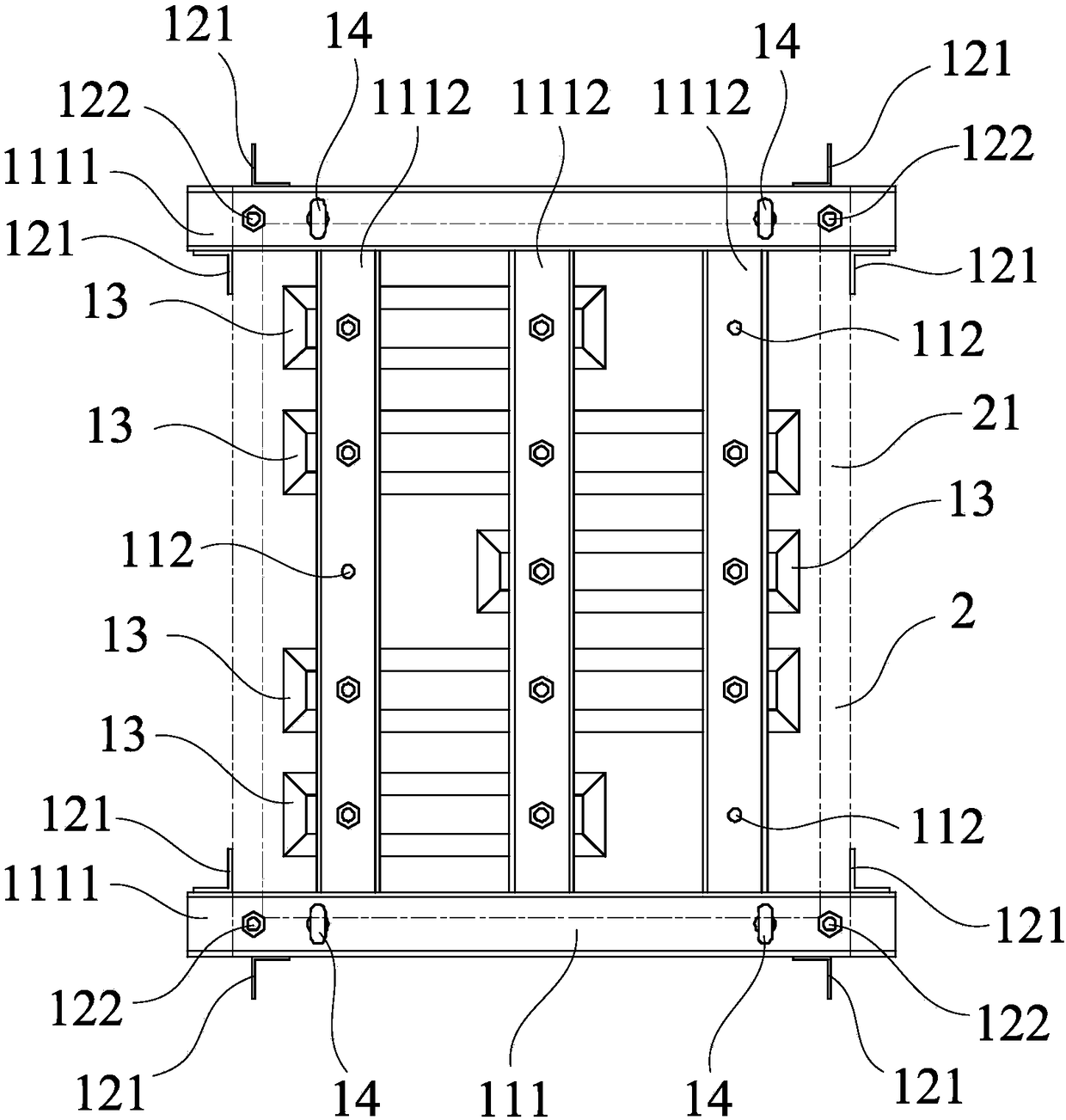

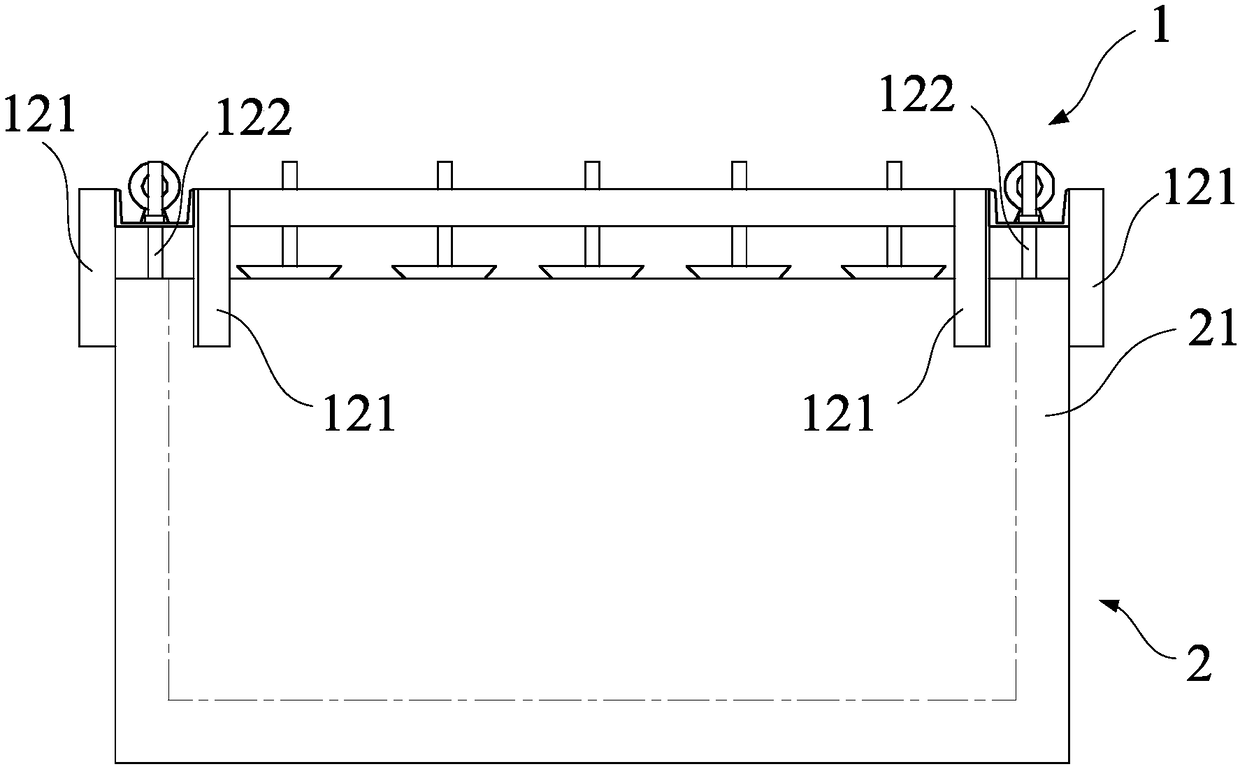

[0046] like figure 1 and figure 2 As shown, the present invention provides a component prefabrication mould for prefabricating concrete components. The component prefabrication mould includes a mould body 2 and a semi-closed suspended formwork 1, wherein the semi-closed suspended formwork 1 is arranged on the top of the mould body 2 for prefabricating the top surface of the concrete component. This semi-closed hanging formwork 1 includes a flat portion 11 , a positioning portion 12 and a plurality of shear key dies 13 .

[0047] The flat portion 11 is provided on the top of the mold body 2 and is horizontally provided. The plane portion 11 includes a plurality of beams 111 , and these beams are connected and fixed to each other to form the main body of the plane portion 11 . Preferably, the beams 111 include two first beams 1111 and a plurality of second beams 1112 . The two first beams 1111 are spaced apart from each other and kept parallel to each other, and both ends o...

Embodiment 2

[0063] like Figure 4 As shown, the structure of the component prefabrication mold of this embodiment is basically the same as that of Embodiment 1, except that the shear key mold 13 of this embodiment does not include the screw 132, and the shear key mold body 131 is welded or screwed. It is fixed below the beam 111 . By directly fixing the shear key mold body 131 on the plane portion 11 , the structural rigidity of the semi-closed suspended formwork 1 of the component prefabrication mold is enhanced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com