Foaming device for producing automobile cushion

A technology of foaming device and car seat cushion, which is applied in the field of car interior processing, which can solve the problems of gel inclusion, gel generation, pipeline blockage and other problems of molded products, and achieve the effect of compact surface quality, promotion of fusion degree and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

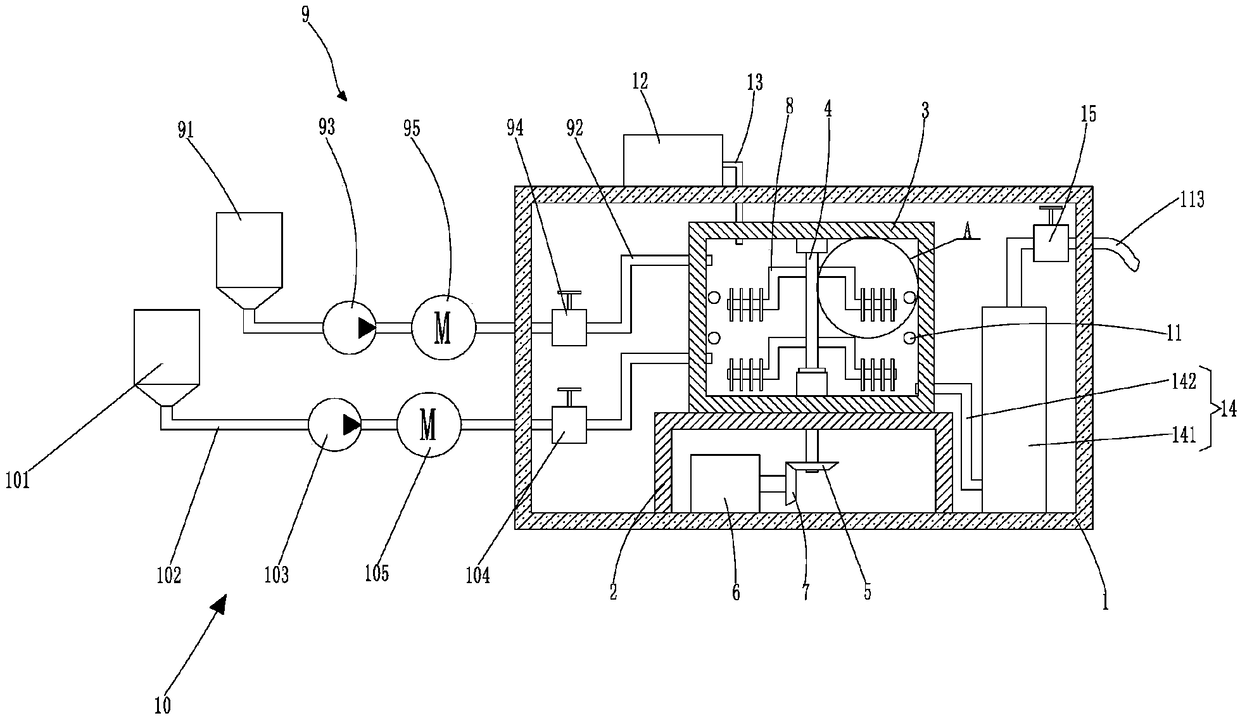

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

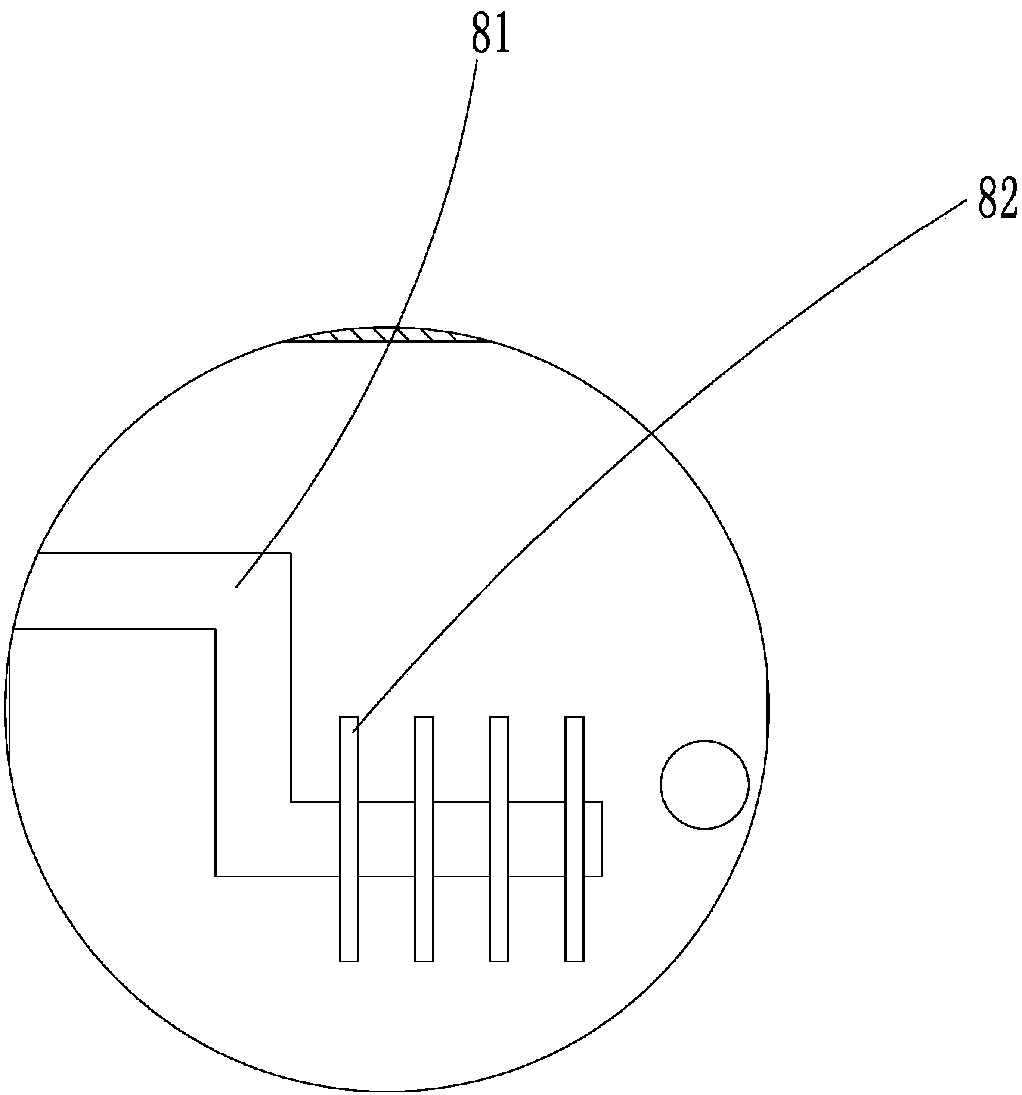

[0018] Such as Figure 1 ~ Figure 2 As shown, a foaming device for producing automobile seat cushions according to the present invention includes a casing 1, and a mixing heating mechanism is provided in the middle of the casing 1, and the mixing heating mechanism includes "ㄇ" fixed on the bottom plate of the casing 1 ”-shaped mounting base 2 and mixing box 3, the mixing box 3 adopts a sealed box with a rectangular structure, and the liquid at the corner can receive the reverse impact force of the side plate of the box to increase the mixing effect. A stirring shaft 4 is rotated in the mixing box 3. The lower end of the stirring shaft 4 extends into the mounting seat 2 and is fixedly connected with a driven gear 5. Stirring blade 8, drive motor 6 is installed in the cabinet 1 below mounting seat 2, and the output shaft of drive motor 6 is fixedly connected with drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com