Air pipe quick joint

An air tube, fast technology, applied in the direction of mechanical equipment, couplings, etc., can solve the problems of easy disengagement, easy loosening, falling off, etc., to achieve the effect of avoiding accidental loosening, improving buckle grip and saving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution will be described in detail below through a best embodiment, but the protection scope of the present invention is not limited to the embodiment.

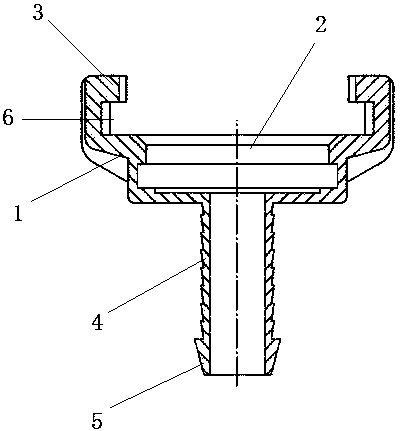

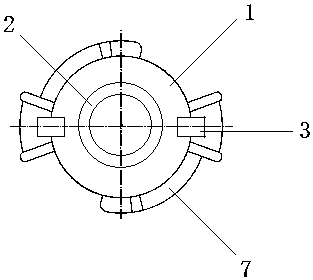

[0020] Such as figure 1 , 2 As shown, an air pipe quick connector includes a connector body, the connector body includes a pipe head 1 and a pipe tail 4, the joint body is integrally cast, and the surface of the pipe head 1 is provided with raised safety barbs 7. The tube head 1 is symmetrically provided with claws 3 along the axis, and the inside of the claws 3 is provided with a slot 6, and the inside of the tube head 1 is provided with a convex sealing gasket 2, and the convex sealing gasket 2 is Smart Compensation Viton Rubber Convex Face Gasket.

[0021] The pipe tail 4 is a fine corrugated pipe tail.

[0022] The distance between the claws 3 is 40mm.

[0023] The end inlet 5 of the pipe tail 4 is set as a smooth bevel.

[0024] The main body of the joint is made of chrome-plated copper alloy....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com