Combined temperature measuring frame and temperature measurement method in heat treatment furnace

A heat treatment furnace and furnace temperature technology, applied in furnaces, furnace components, lighting and heating equipment, etc., can solve problems such as fixing temperature measuring elements, and achieve the effects of convenient use, wide application range, and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

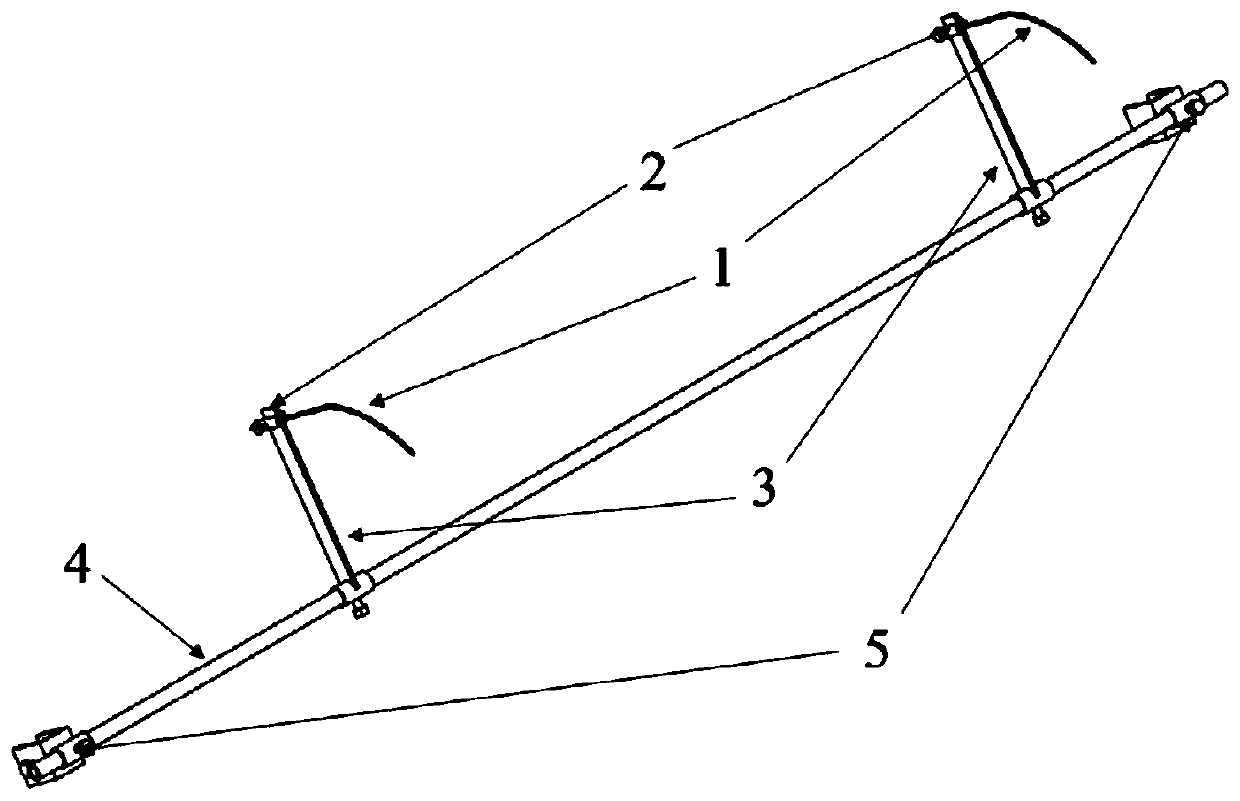

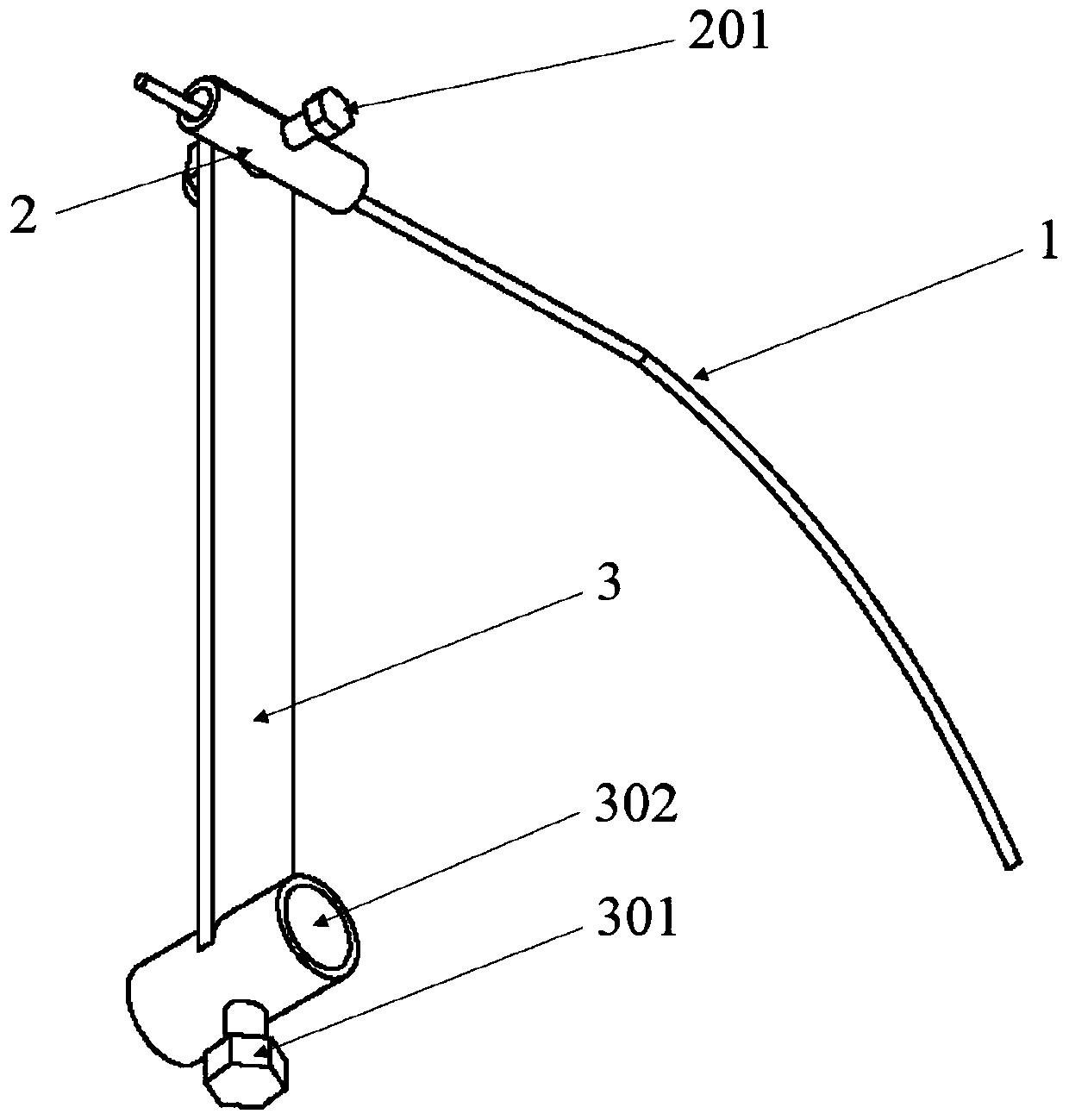

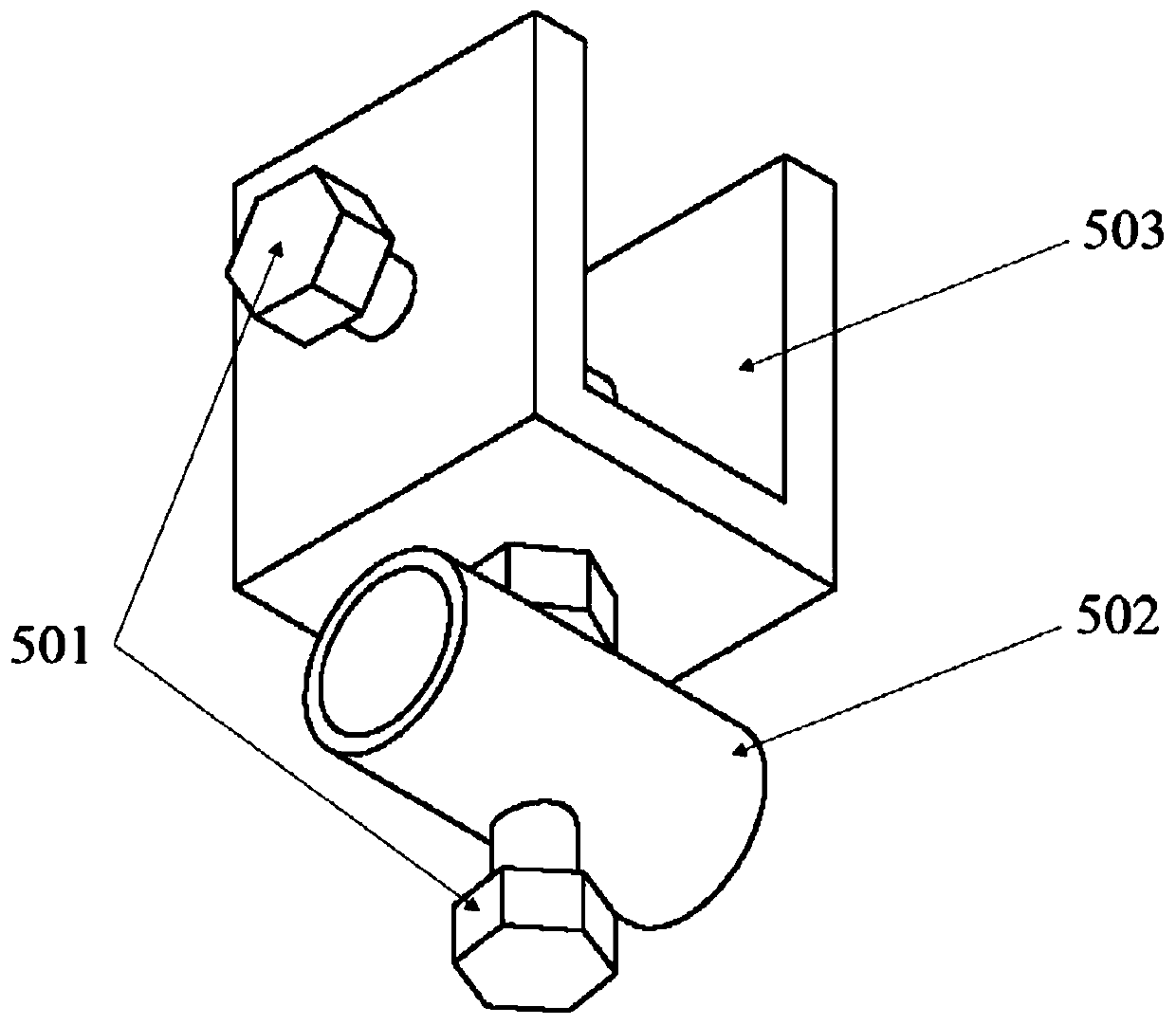

[0030] combine figure 1 , figure 2 and image 3 As shown, the combined temperature measuring frame includes at least one set of temperature measuring frame components, and the temperature measuring frame component includes a temperature measuring element support rod 3, a connecting rod 4 and a connecting rod fixing fixture 5; the temperature measuring element supporting rod 3 A temperature measuring element fixing structure, a connecting structure and a locking structure are arranged on the connecting rod fixing fixture 5, and at least two connecting parts are arranged on the connecting rod fixing fixture 5; the supporting rod 3 of the temperature measuring element is slidably arranged on the connecting rod through the connecting structure 4, and can rotate around the connecting rod 4; the locking structure can limit the sliding of the temperature measuring element ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com