High-tension porcelain insulator for oil permeation preventing transformer

A high-voltage porcelain bottle and transformer technology, which is applied in the field of transformers, can solve the problems of reducing the service life of high-voltage porcelain bottles, effectively preventing oil leakage, and affecting the surrounding environment, so as to achieve the effects of not being easy to penetrate cooling oil, preventing cooling oil penetration, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

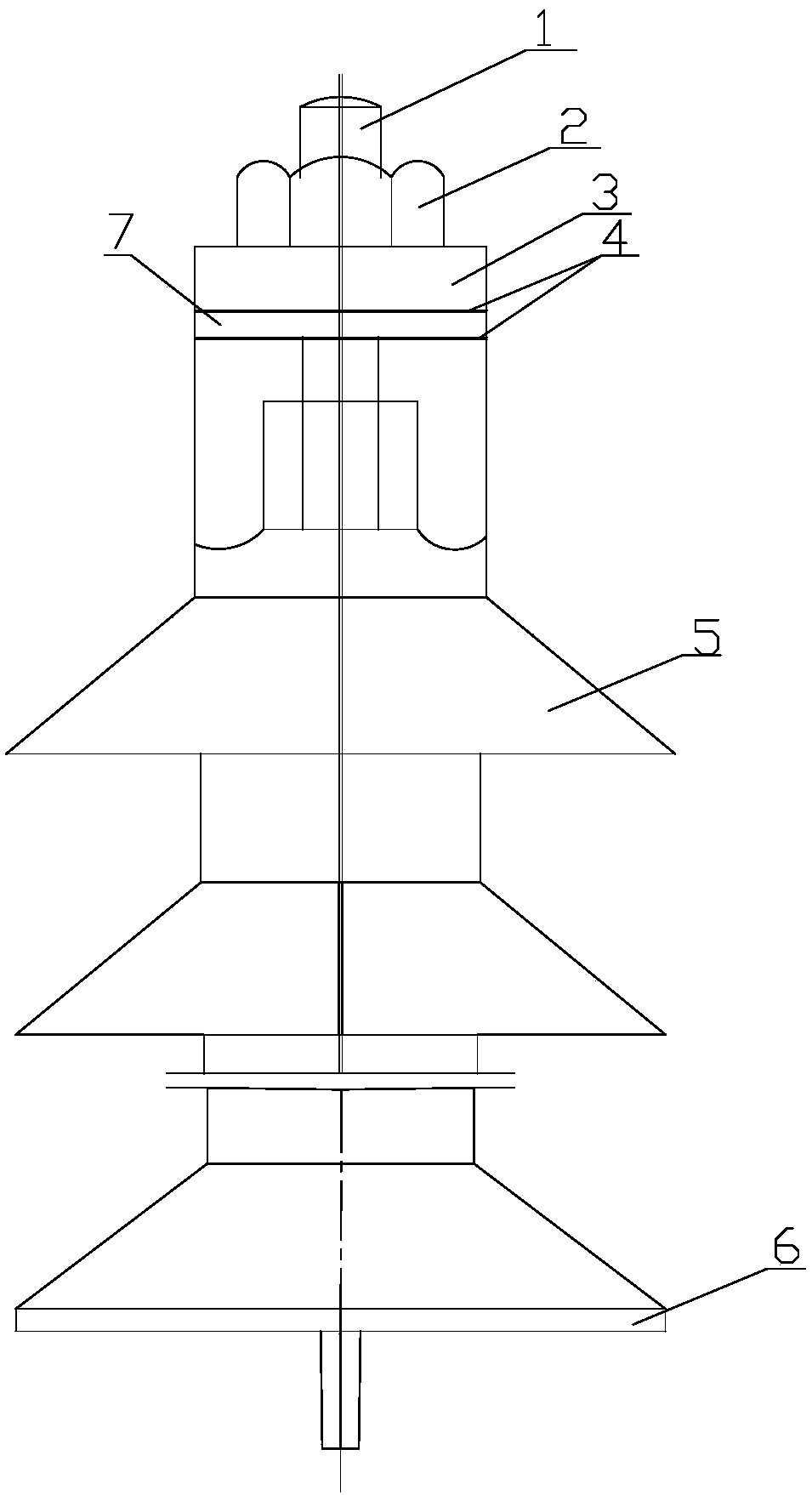

[0012] Such as figure 1 As shown, the anti-seepage oil transformer high-voltage porcelain bottle of the present invention includes a conductive rod 1, a porcelain bottle body 5 is set on the conductive rod 1, a nut 2 is arranged on the top of the porcelain bottle body 5, and a positioning plate 6 is arranged at the bottom, and the nut 2 and the porcelain bottle body 5 The porcelain sleeve 3 and the sealing gasket 7 are set in sequence from top to bottom, the nut 2, the positioning plate 6, the porcelain sleeve 3 and the sealing gasket 7 are all set on the conductive rod 1, and the sealing gasket 7 and the porcelain bottle body 5 are sealed. An oil-repellent paint layer is arranged on the contact surface between the pad 7 and the porcelain sleeve 3, and an oil-repellent paint layer 4 is coated on the contact surface between the upper end of the porcelain bottle body 5 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com