Control device for preventing tower-shaped coil discharging

A control device and tower-shaped technology, applied in the field of control devices and control devices for preventing tower-shaped coil unloading, to achieve the effects of eliminating edge folding, improving the quality of the outer surface of the strip, and improving the quality of the plate shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

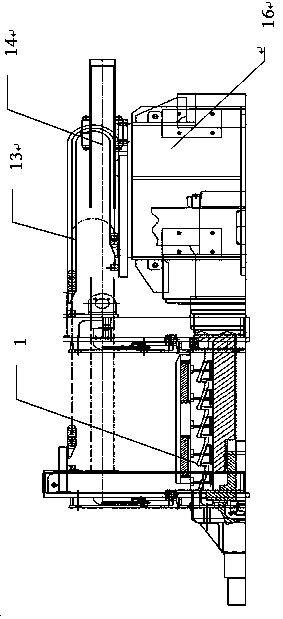

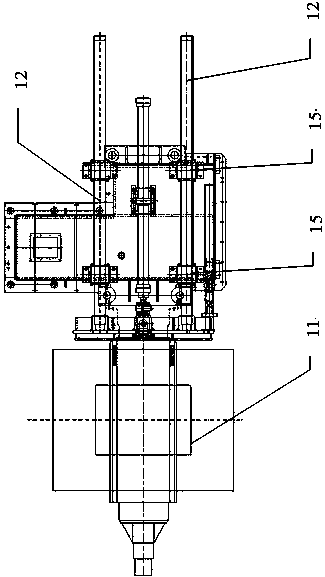

[0032] Example 1: see Figure 1-Figure 5 , A control device for preventing tower-shaped unwinding, said control device comprising a support assembly, a pressing assembly and a following assembly, the support assembly comprising a guide roller bearing 5, a guide roller 6 and a tongue 10, the pressing assembly It includes a cylinder 3, a compression spring 4, a guide plate sliding groove 7, a pressure plate 8, and a connecting rod 9. The cylinder 3 piston rod head is fixedly connected to the connecting plate in the middle of the connecting rod 9 bracket by a nut, and the connecting rod 9 is threaded Connected to the pressure plate 8, a set of compression springs 4 are respectively provided on both sides of the pressure plate 8, a convex structure guide roller 6 is provided under the guide plate chute 7, and the guide roller 6 is provided on the guide roller bearing 5. The assembly includes an executive guide rod 12 and an oil cylinder 14. The synchronous action of the guide rod 1...

Embodiment 2

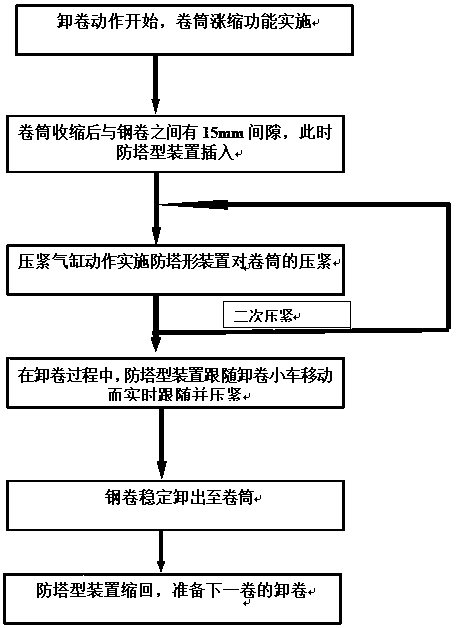

[0033] Example 2: see Figure 1-Figure 5 , A control method of a control device preventing tower unloading, the method is as follows:

[0034] 1) The strip steel is successfully coiled into a coil without overflow, and the expansion and contraction function of the coil is implemented;

[0035] 2) There is a 15mm gap between the reel and the steel coil after shrinking, and the anti-tower device is inserted at this time;

[0036] 3) The compression cylinder action implements the anti-tower device to compress the reel;

[0037] 4) The unloading action starts. During the unloading process, the anti-tower type device follows the unloading trolley to move and follow and press it in real time;

[0038] 5) The steel coil is stably discharged to the reel;

[0039] 6) The anti-tower device is retracted to prepare for the unloading of the next roll.

[0040] In the step 1), in order to ensure the quality of the coil shape when the strip is crimped, this unit adopts 9 CPC correction devices to contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com