Drill bit sleeve

A kind of drill sleeve and drill bit technology, which is applied in drilling/drilling equipment, parts of boring machine/drilling machine, measurement of positioning in boring machine/drilling machine, etc. It can solve the problems of large dust, difficult cleaning, drilling through plates, etc., and achieve Anti-splash operator, convenient control, and operator protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

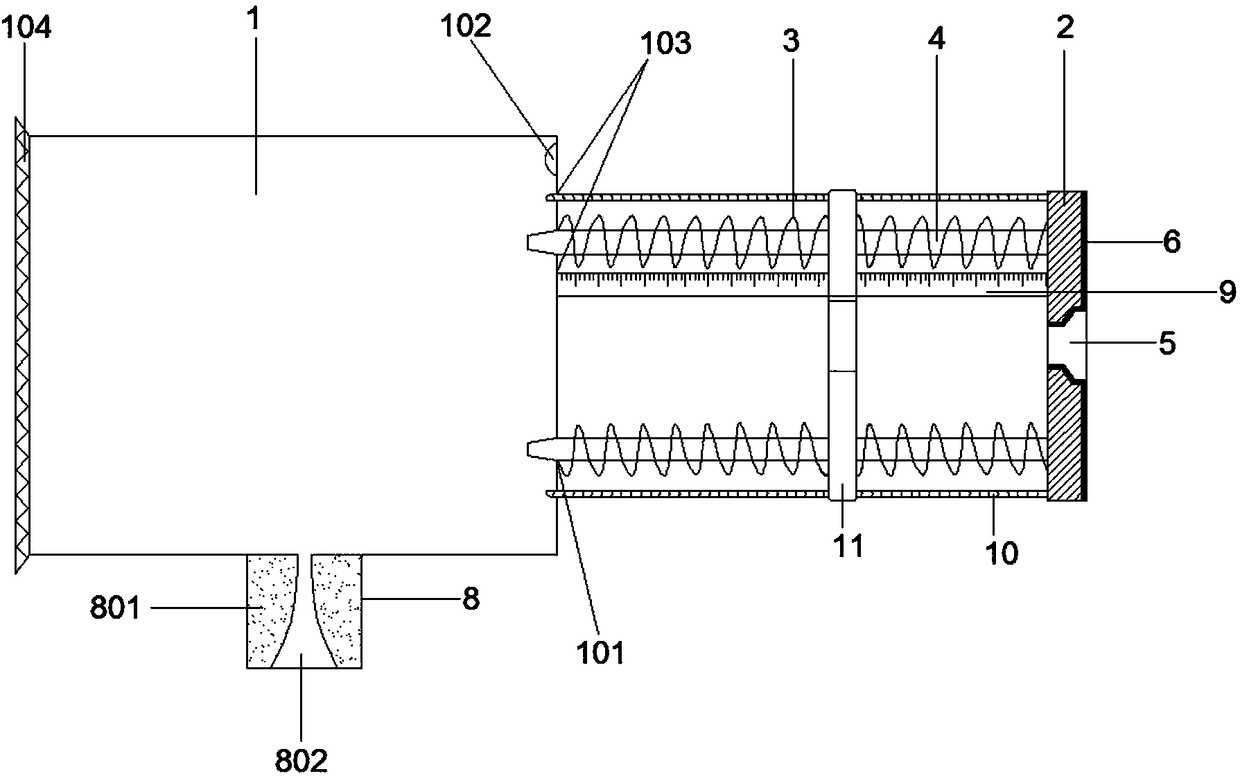

[0037] Such as figure 1 and 7 , a drill sleeve, including a cylinder 1, a base 2, and a guide member with an elastic member sheathed on the outside; the elastic member is a spring 3; the guide member is a plurality of stems circumferentially arranged on the base 4. One end of the stem is fixed on one side of the base 2, and the other end is movably arranged in the first through hole 101 opened on one side of the cylinder 1; the two ends of the spring 3 are respectively connected to the surface of the cylinder 1 and the base 2 The center of the base 2 is provided with a connection hole 5 for inserting the drill bit 100 and matching the surface of the drill tool 200 at the end of the drill bit; the base 2 and connection hole 5 are attached to the surface of the drill tool 200 at the end of the drill bit The joint is provided with a fastening structure; the fastening structure is a strong adhesive layer 6; the outer surface of the strong adhesive layer 6 is provided with a hand-...

Embodiment 2

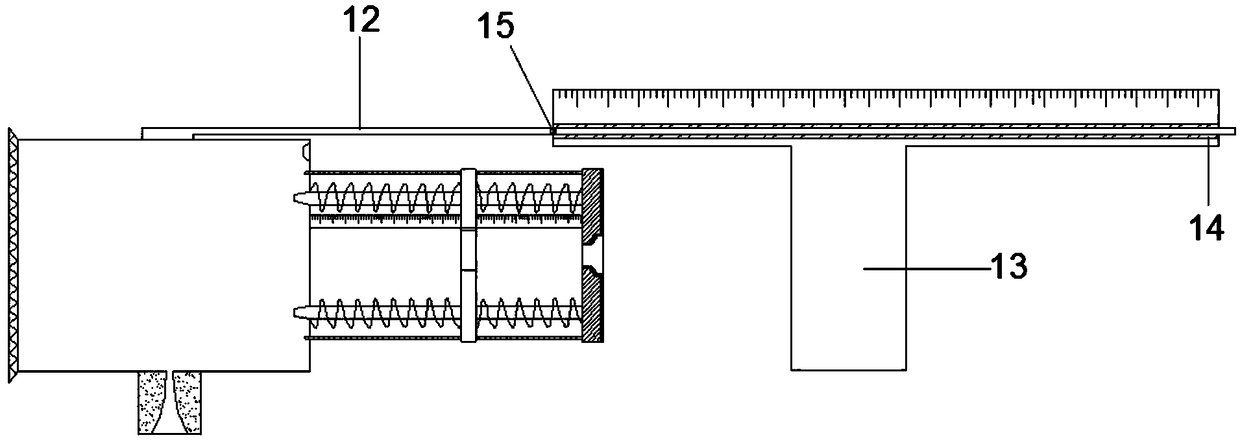

[0049] Such as figure 2 , The difference from Embodiment 1 is that this embodiment also includes a distance measuring rod 12 connected to the top of the cylinder 1, and a T-shaped ruler 13 that can be clamped on the drill tool 200; the T-shaped ruler 13 is equipped with There is a transparent observation hole 14 for the distance measuring rod 12 to slide through; a scale is marked above the transparent observation hole 14; the distance measuring rod has a zero mark 15 at the initial position corresponding to the scale in the initial state position. When in use, the distance / depth of the drilled hole by the electric drill is the distance that the cylinder 1 moves, and then reflected on the distance measuring rod 12 connected to it, the distance measuring rod 12 slides in the transparent observation hole 14, and the zero mark 15 points to the corresponding scale. This design enables the operator to know the distance / depth of the drilling in real time, facilitates the control of...

Embodiment 3

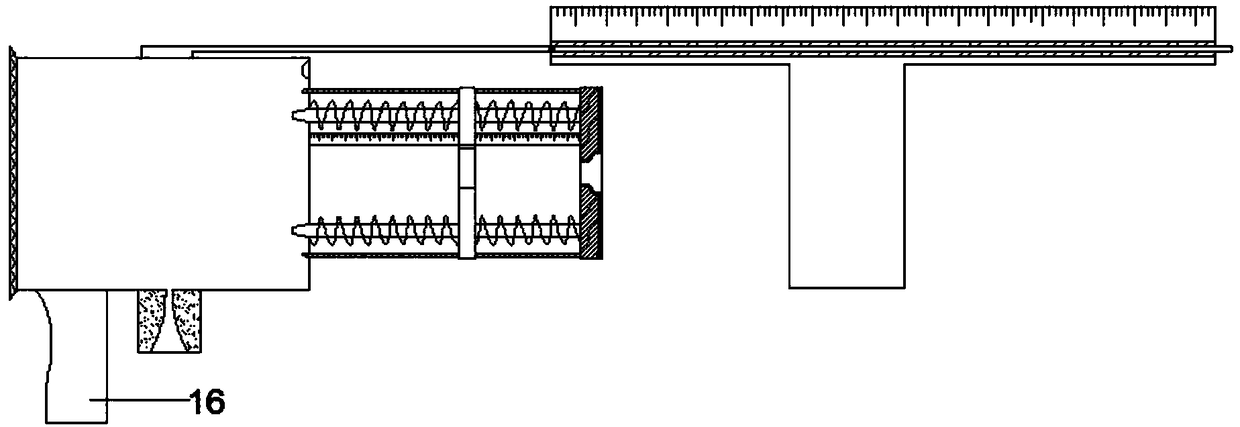

[0051] Such as image 3 , the difference from the second embodiment is that this embodiment also includes an auxiliary handle 16 connected to and arranged under the barrel 1 . When the operator uses the device, he holds the electric drill in one hand and the auxiliary handle 16 in the other hand, which can make the swing range of the cylinder body 1 smaller, and the stability and convenience of the equipment are better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com