Four-axle rotary machining fixture

A rotary machining and jig technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of poor machining accuracy, poor workpiece positioning accuracy, single processed products, etc., to enhance flexibility and versatility , to ensure the effect of machining accuracy and positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

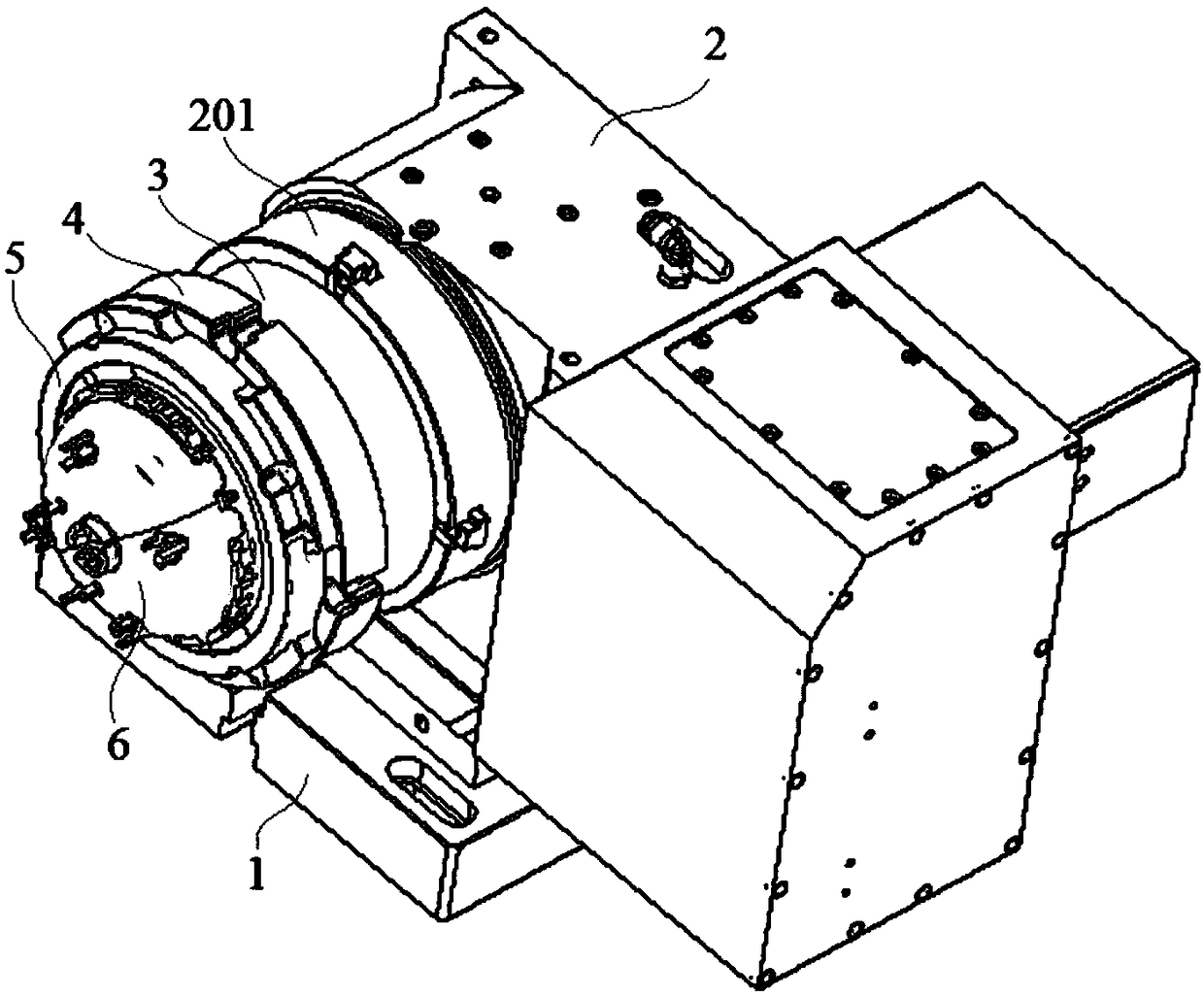

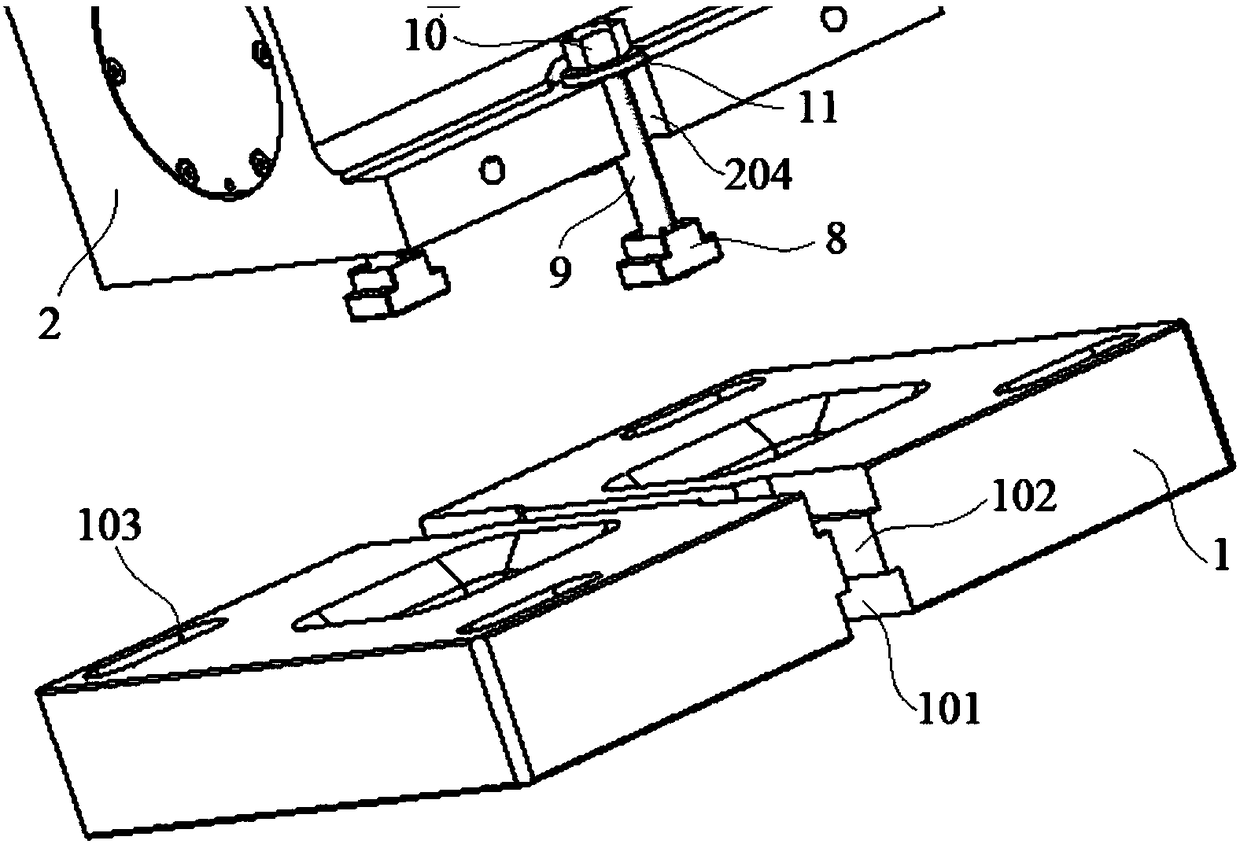

[0026] Embodiment 1: A four-axis rotary processing fixture, including a base 1, a four-axis body 2, an adapter plate 3, a carrier plate 4 and a pressure ring 5, the lower surface of the four-axis body 2 is connected to the base 1, and the four-axis The side of the main body 2 is provided with an output end 201, the adapter plate 3 is fixedly connected to the output end 201 of the four-axis body 2, the carrier plate 4 is fixedly connected to the adapter plate 3, and a workpiece 6 is connected to the carrier plate through the pressure ring 5 4 contact connections;

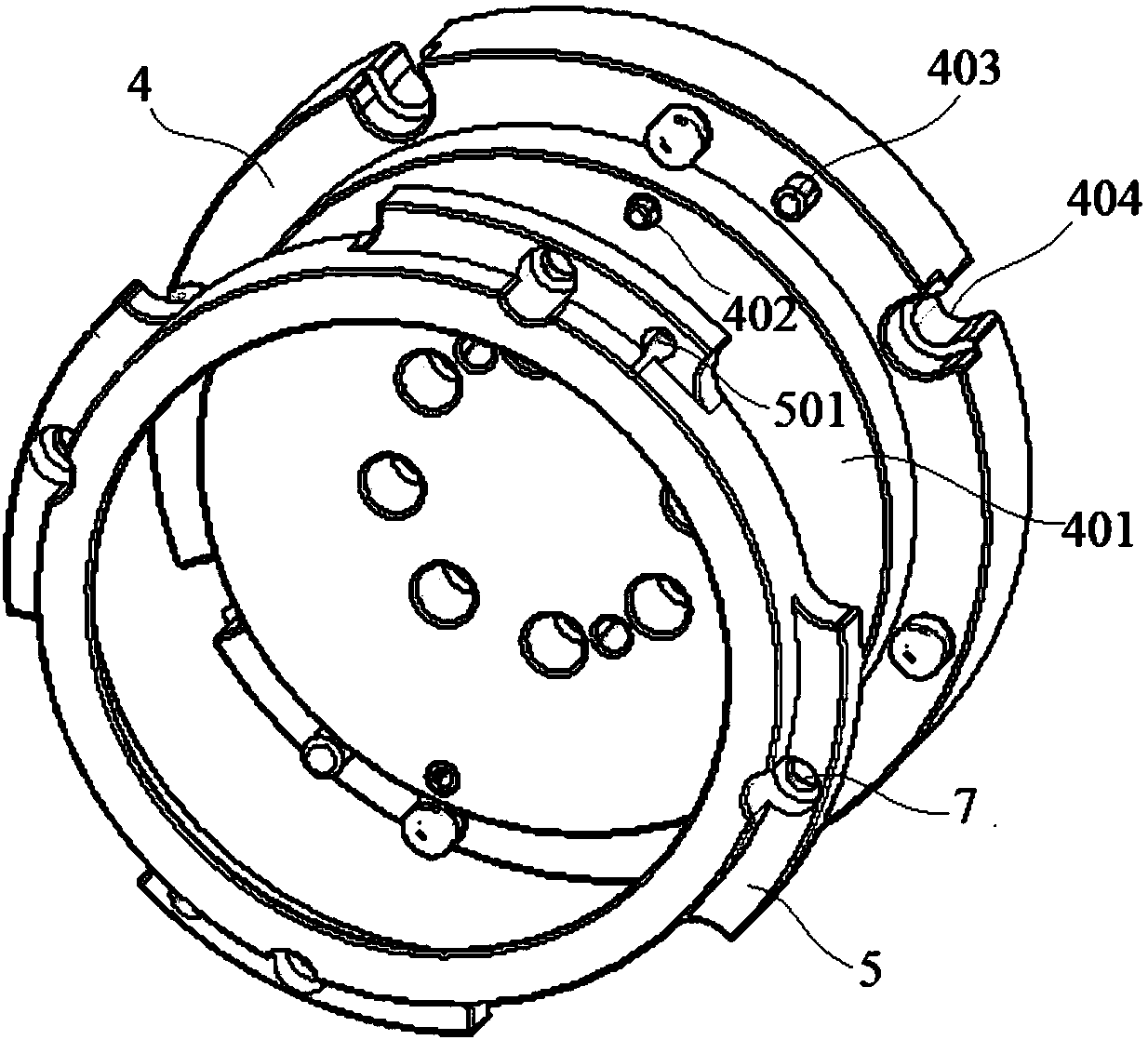

[0027] There is a circular boss 401 in the center of the top surface of the carrier plate 4, and a plurality of pins 402 are arranged on the edge of the circular boss 401. The edge of the workpiece 6 has pin holes 601 for the pins 402 to be embedded in. The carrier plate 4 The edge is provided with a number of limit posts 403, and the edge of the pressure ring 5 is provided with a limit hole 501 corresponding to the ...

Embodiment 2

[0031] Embodiment 2: A four-axis rotary processing fixture, including a base 1, a four-axis body 2, an adapter plate 3, a carrier plate 4 and a pressure ring 5, the lower surface of the four-axis body 2 is connected to the base 1, and the four-axis The side of the main body 2 is provided with an output end 201, the adapter plate 3 is fixedly connected to the output end 201 of the four-axis body 2, the carrier plate 4 is fixedly connected to the adapter plate 3, and a workpiece 6 is connected to the carrier plate through the pressure ring 5 4 contact connections;

[0032] There is a circular boss 401 in the center of the top surface of the carrier plate 4, and a plurality of pins 402 are arranged on the edge of the circular boss 401. The edge of the workpiece 6 has pin holes 601 for the pins 402 to be embedded in. The carrier plate 4 The edge is provided with a number of limit posts 403, and the edge of the pressure ring 5 is provided with a limit hole 501 corresponding to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com