Tempered glass stock rack

A technology of tempered glass and racks, which is applied to rigid containers, bottle/can parts, and packaging of vulnerable items. It can solve the problems of small glass placement, low practical performance, and increased production costs, and reduce production. cost, the effect of enhancing practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

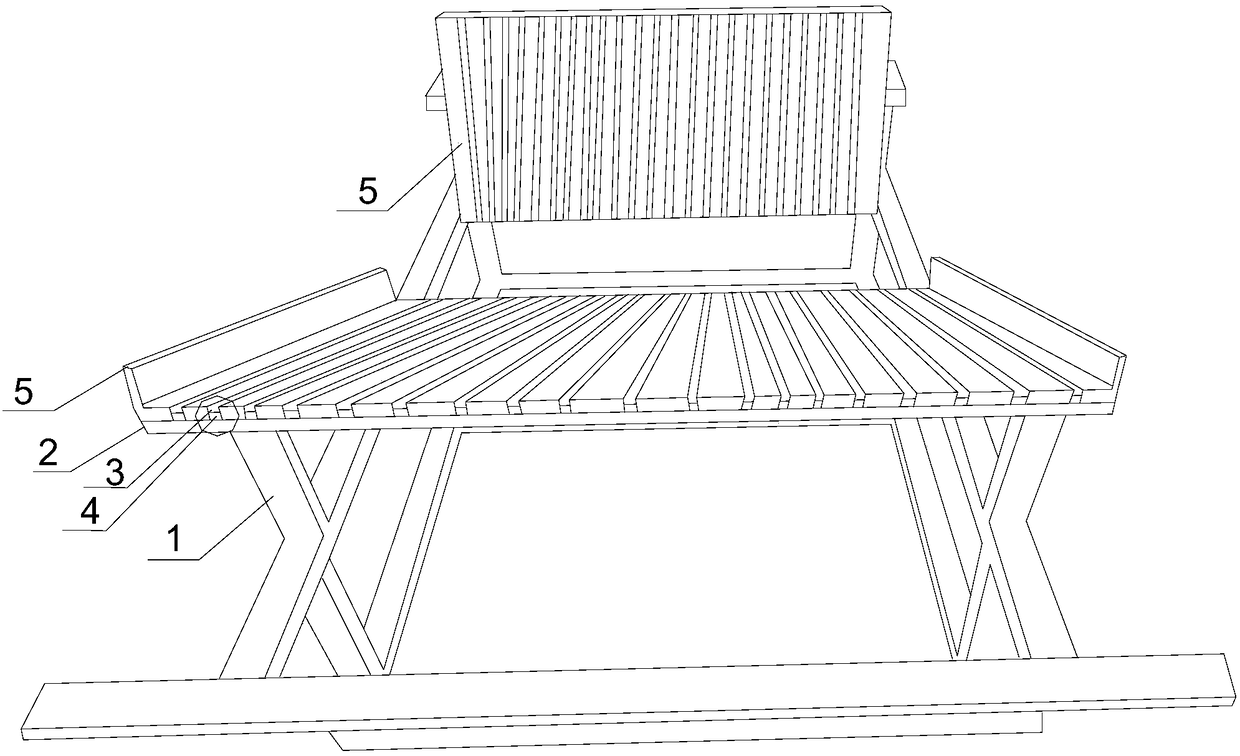

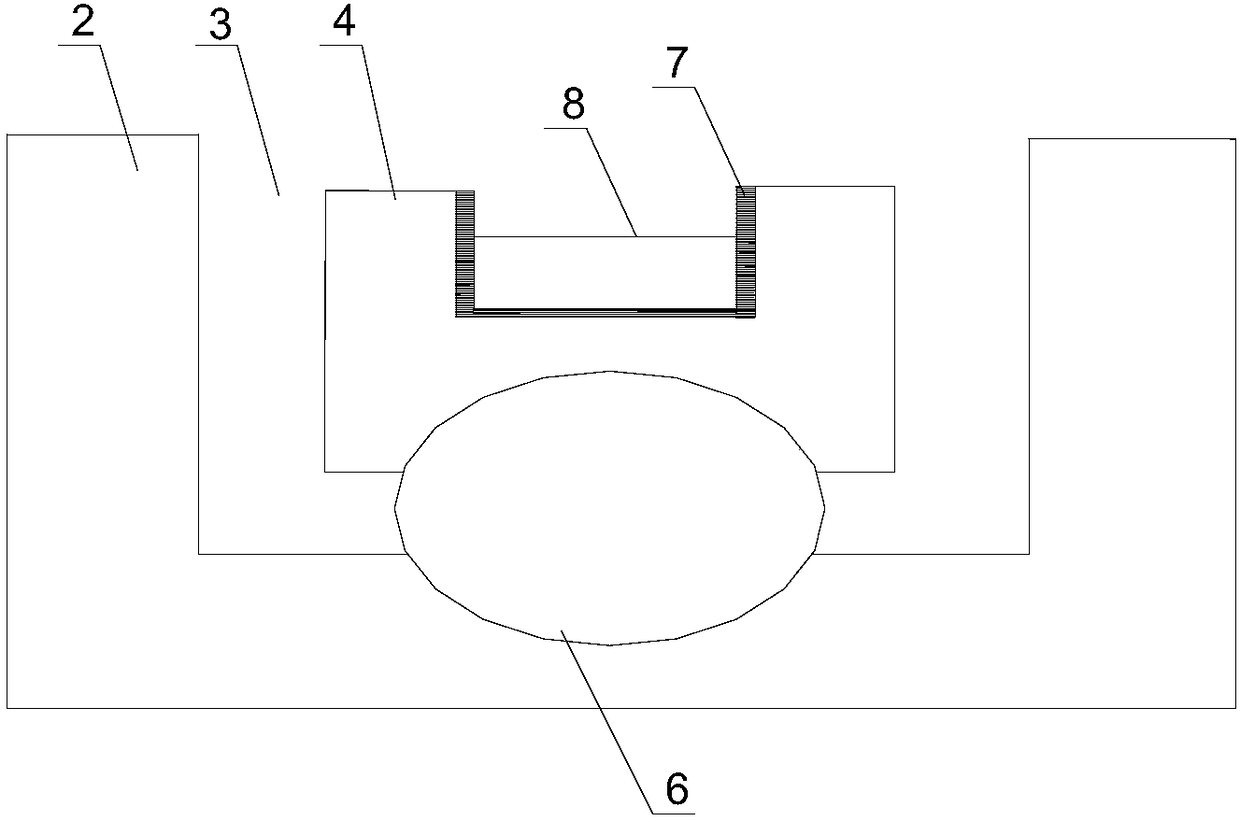

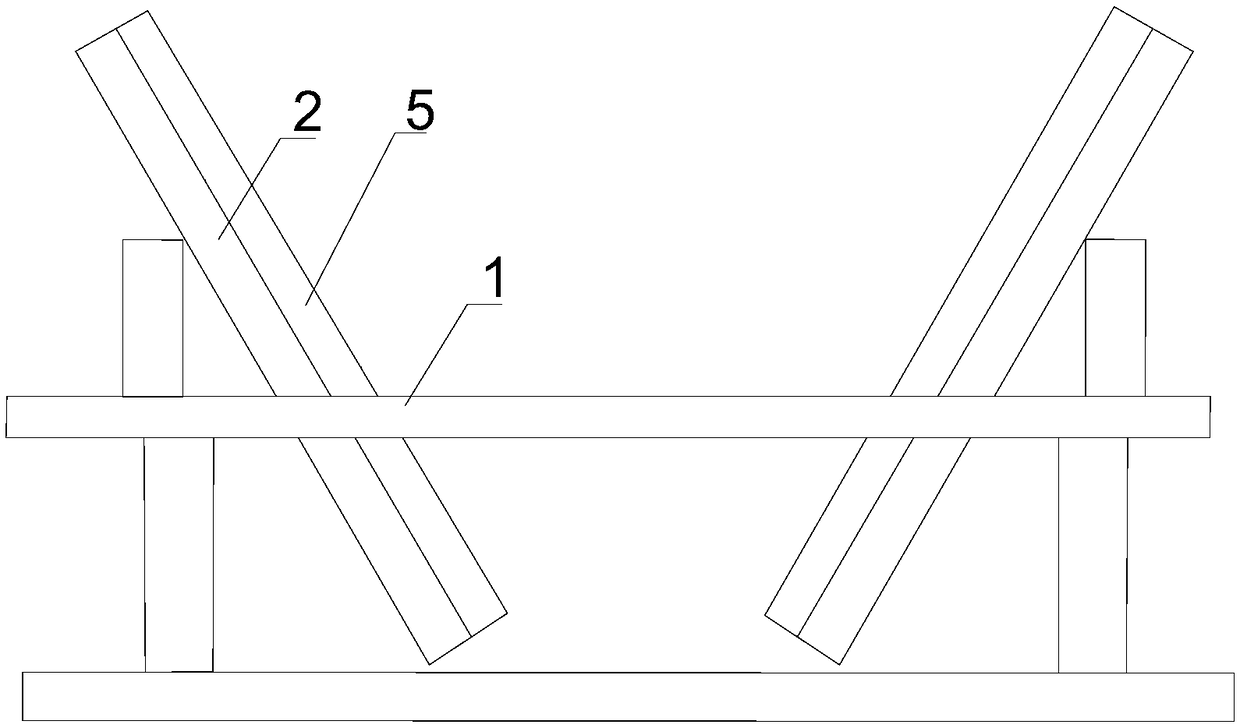

[0024] Such as figure 1 , figure 2 with image 3 As shown, the tempered glass placement rack of the present invention includes a bracket 1 and two obliquely arranged baffles 2. The two baffles 2 are arranged opposite to each other on the bracket 1, and the inclination angles of the two baffles 2 are the same, and also includes a placement slot 3 and a sliding groove 4, the placing groove 3 is arranged on the baffle 2 along the oblique direction of the baffle 2, the sliding groove 4 is arranged in the placing groove 3 through the rotating shaft 6, and the width of the placing groove 3 is larger than that of the sliding groove 4 The width of the baffle 2 is 45°-60°; the inner wall of the sliding groove 4 is provided with a rubber pad 7. Because of the special shape of the curved glass, most companies adopt the on-site plane placement, so that the curved glass occupies a larger space and working environment when placed, increases the work intensity of the workers during access, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com