Flame-retardant compound polyether polyol for bus roofs, polyurethane foam and preparation method thereof

A technology of polyether polyol and polyurethane foam, applied in the field of polyurethane, can solve the problems of being easy to burn, not having flame retardant properties, and threatening the safety of life and property of car owners.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The present application also provides a method for preparing the above polyurethane foam, which includes the following steps: foaming after mixing the polyurethane raw material composition.

[0059] The mixing method and conditions can be conventional methods and conditions in the art, and the mixing temperature is conventional in the art, preferably 5-15°C. The mixing operation is preferably carried out according to the following steps: stirring at a rotation speed of 3000-4000 revolutions per second (r / s) for 2-3s.

[0060] The foaming method and conditions described herein are conventional methods and conditions in the art, generally free foaming molding at room temperature.

[0061] On the basis of conforming to common knowledge in the field, the above-mentioned preferred conditions can be combined arbitrarily to obtain the preferred examples of the present application.

[0062] The reagents and raw materials used in this application are all commercially available....

Embodiment 1

[0067] (1) The preparation method of combination polyether:

[0068] Put the polyether polyol NJ-330N (75 parts), NJ-6209 (20 parts), MN-700 (5 parts) in the reaction kettle, add the catalyst PMDETA (1 part), BX405 (3 parts), B8870 in sequence (1.5 parts), TCPP (20 parts) and deionized water (35 parts), stir well;

[0069] (2) A preparation method of high flame-retardant all-water low-density spray polyurethane foam:

[0070] Take 1 part of the above combined polyether and 1 part of polyphenyl polymethylene polyisocyanate in a polytetrafluoroethylene cup, control the temperature of the material at 10°C, stir at a speed of 4000r / s for 3s, and freely foam at room temperature After that, you get it.

[0071] The density of gained full water low-density polyurethane foam is 6.8kg / m 3 , the oxygen index is 22.8%.

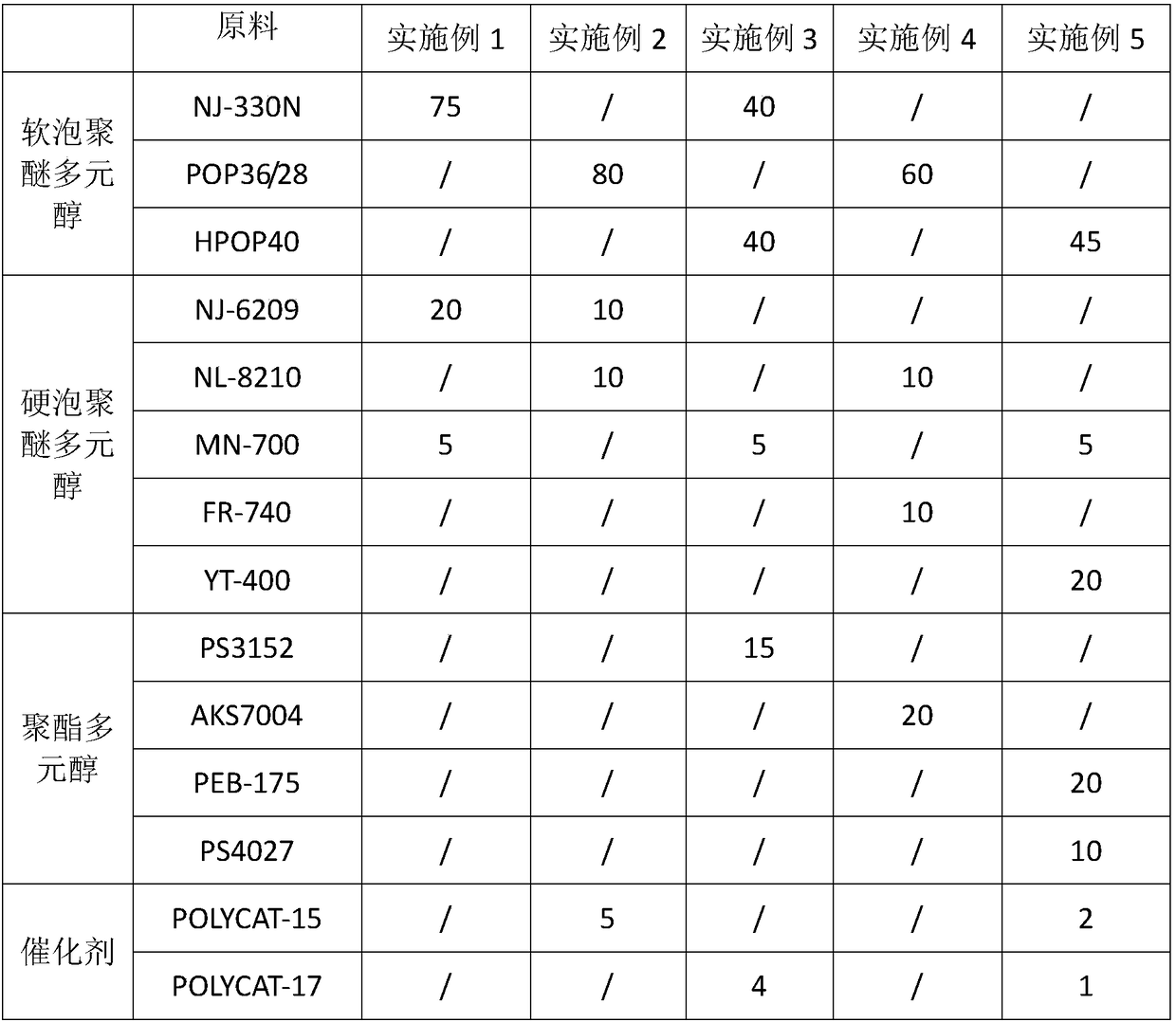

Embodiment 2-5

[0073] Examples 2-5 According to the method of Example 1, a kind of flame-retardant combination polyether polyol and polyurethane foam for passenger car roof was prepared.

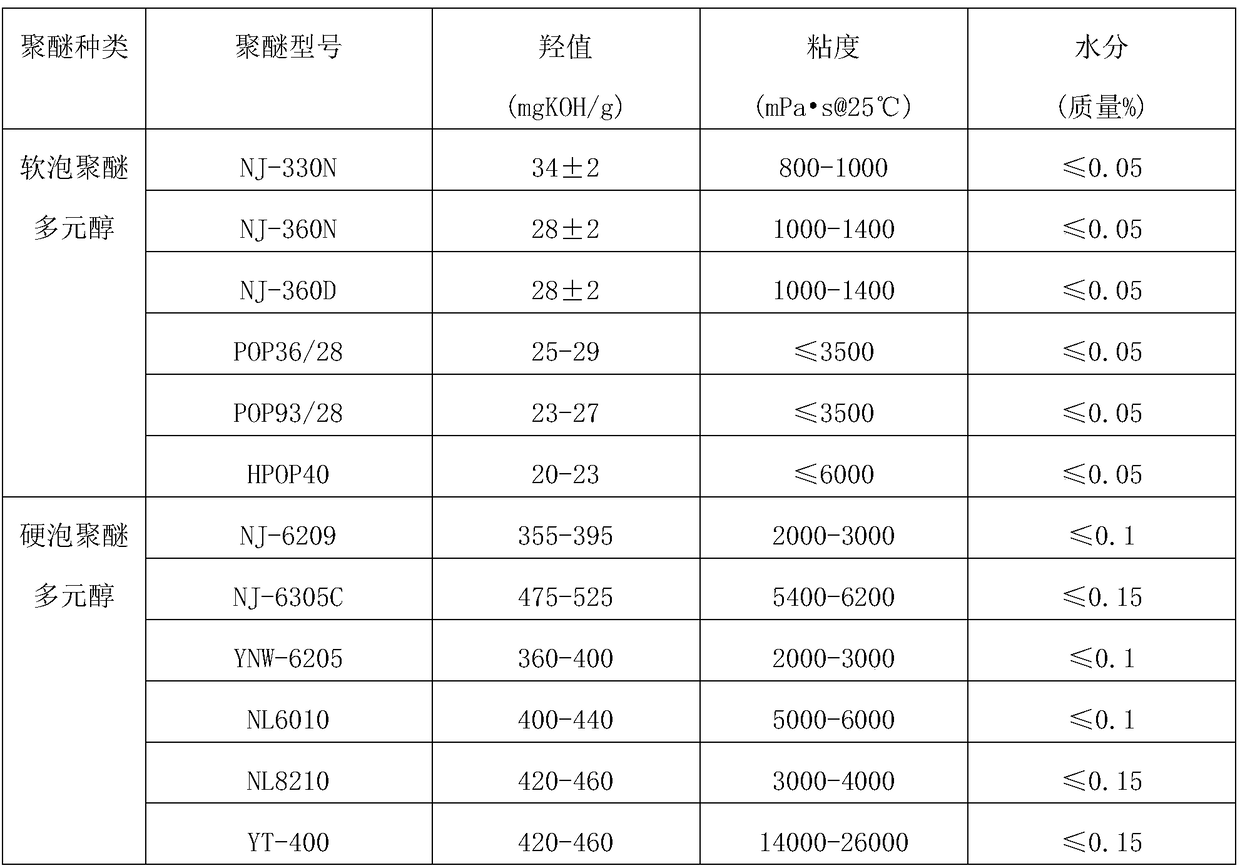

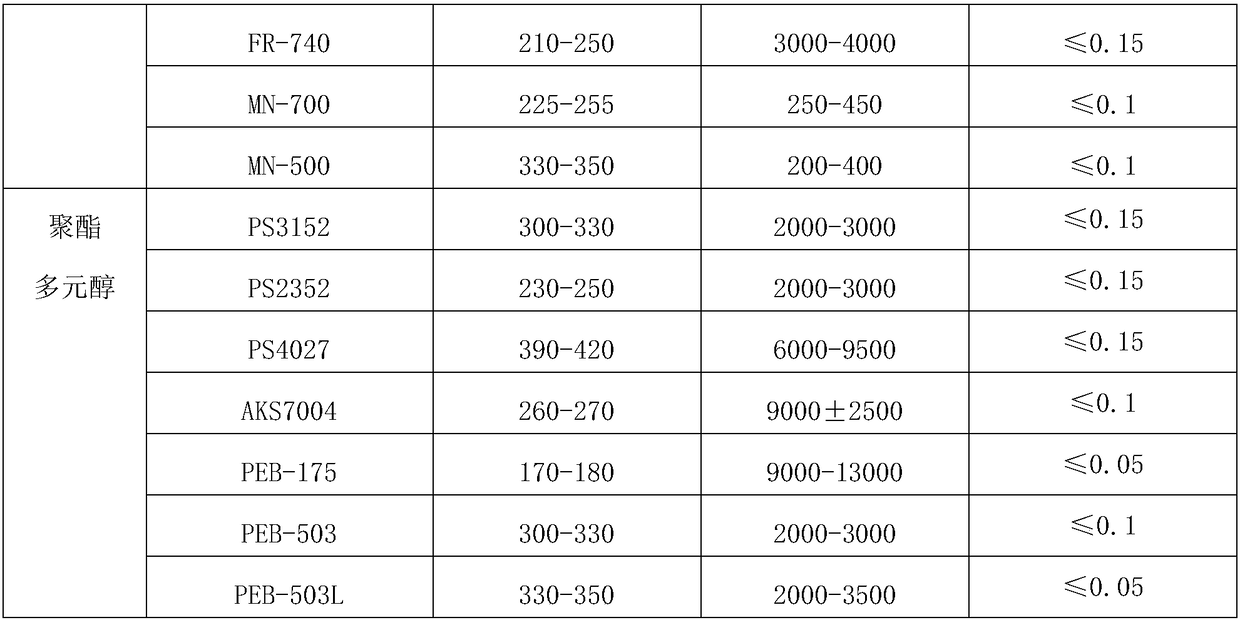

[0074] The formula data of embodiment 1-5 is as shown in table 2.

[0075] The properties of the foams obtained in Examples 1-5 are shown in Table 3.

[0076] The formula data sheet of table 2 embodiment 1-5

[0077]

[0078]

[0079] The performance table of gained foam in the embodiment 1-5 of table 3

[0080] performance

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com