A kind of wool nitrile dyeing process

A wool nitrile and process technology, applied in the field of wool nitrile dyeing process, can solve the problems of large water consumption, difficult to control cleanliness, waste of water resources, etc., and achieve the effects of avoiding steam outflow, small color difference, and improving dyeing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

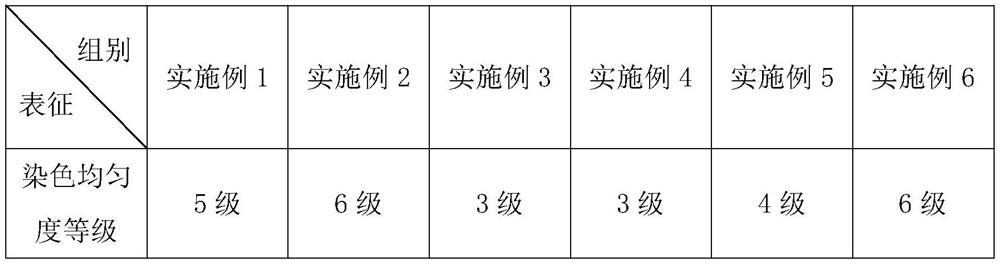

Examples

Embodiment 1

[0025] Embodiment 1, a kind of dyeing process of wool nitrile mainly comprises the following steps:

[0026] Step S1, hang the yarn into the vat, hook the wool nitrile skein to the steam pipe in the dyeing vat (the dyeing vat is produced by the Boiler Operation Department of Dalang Zhongshun, Dongguan City) at certain intervals;

[0027] Step S2: In the first stage, the skein is soaked into the material, and water is passed into the dye vat, and the dispersant is added and then stirred. The heating system of the dye vat heats the water and raises the temperature to 40°C, and then adds neutral dye (neutral orange RL) ;

[0028] Step S3, the first stage of temperature-rising dyeing, for the wool nitrile skein that needs to be dyed to a light color, the temperature-rising speed is 1°C / min to carry out temperature-rising dyeing, and dyeing to 70°C, and then add cationic dyes (using cationic yellow X-6G as As a cationic dye), heat up to 100°C at a heating rate of 1min / °C and keep ...

Embodiment 2

[0032] Example 2, a wool nitrile dyeing process, differs from Example 1 in that in step S3, after dyeing to 75°C, the temperature continues to rise to 80°C, and then the temperature is raised to 90°C within 1.5min / °C. °C, and then heated to 100 °C within 1 min / °C.

Embodiment 3

[0033] Example 3, a wool nitrile dyeing process, the difference from Example 1 is that in the step S3, after dyeing to 75°C, continue to heat up to 80°C, and then heat up to 90°C within 2min / °C , and then heated up to 100°C within 1min / °C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com