Rapid dust falling device and method for tunnel construction

A dust suppression device and tunnel construction technology, applied in safety devices, dust prevention, earth-moving drilling and other directions, can solve the problems of inability to meet the requirements of tunnel construction environment, endanger the health of tunnel construction workers, and generate a large amount of toxic and harmful gases, etc. The effect of waiting time for dust reduction, shortening dust reduction time, and avoiding close contact with dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

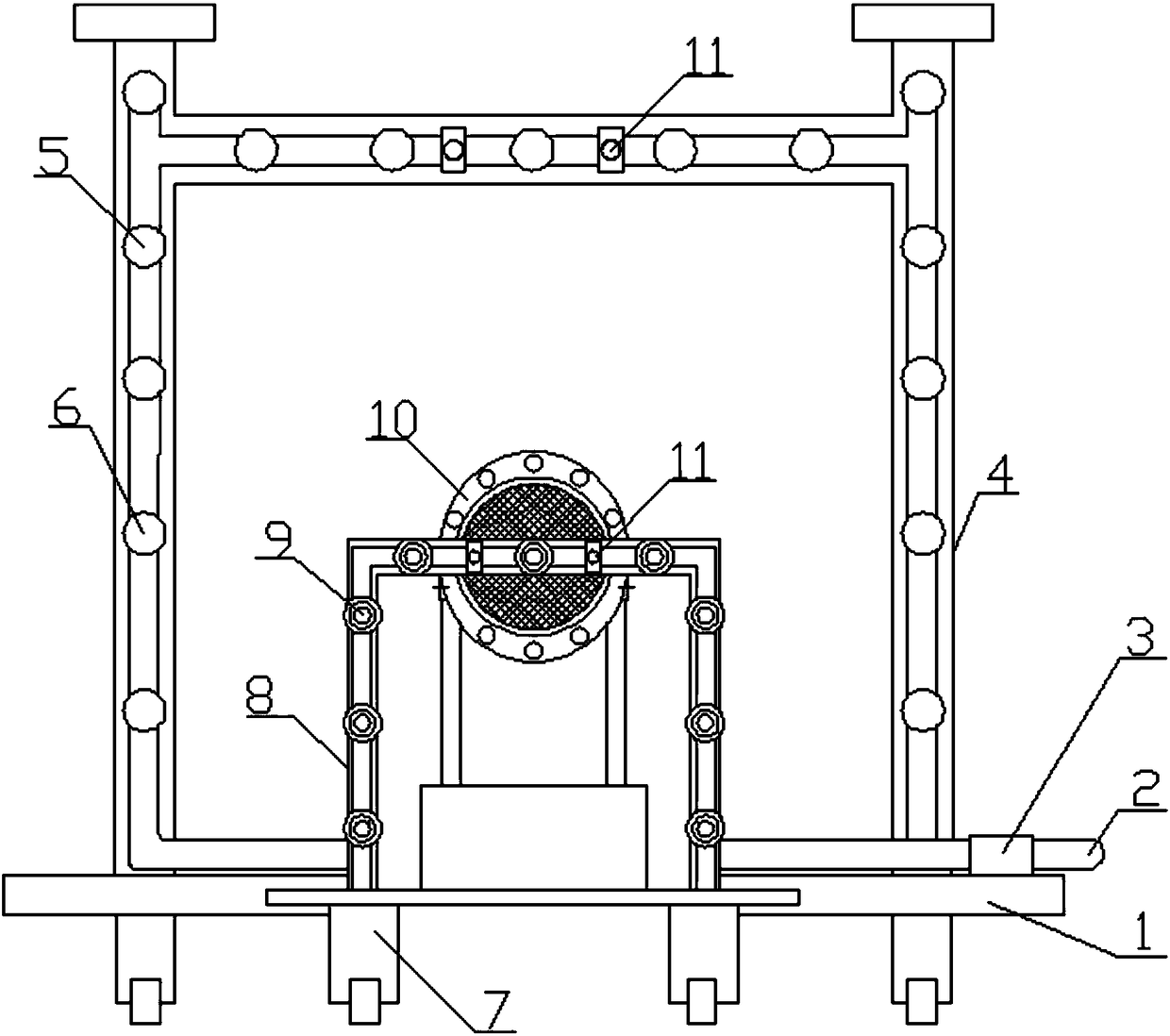

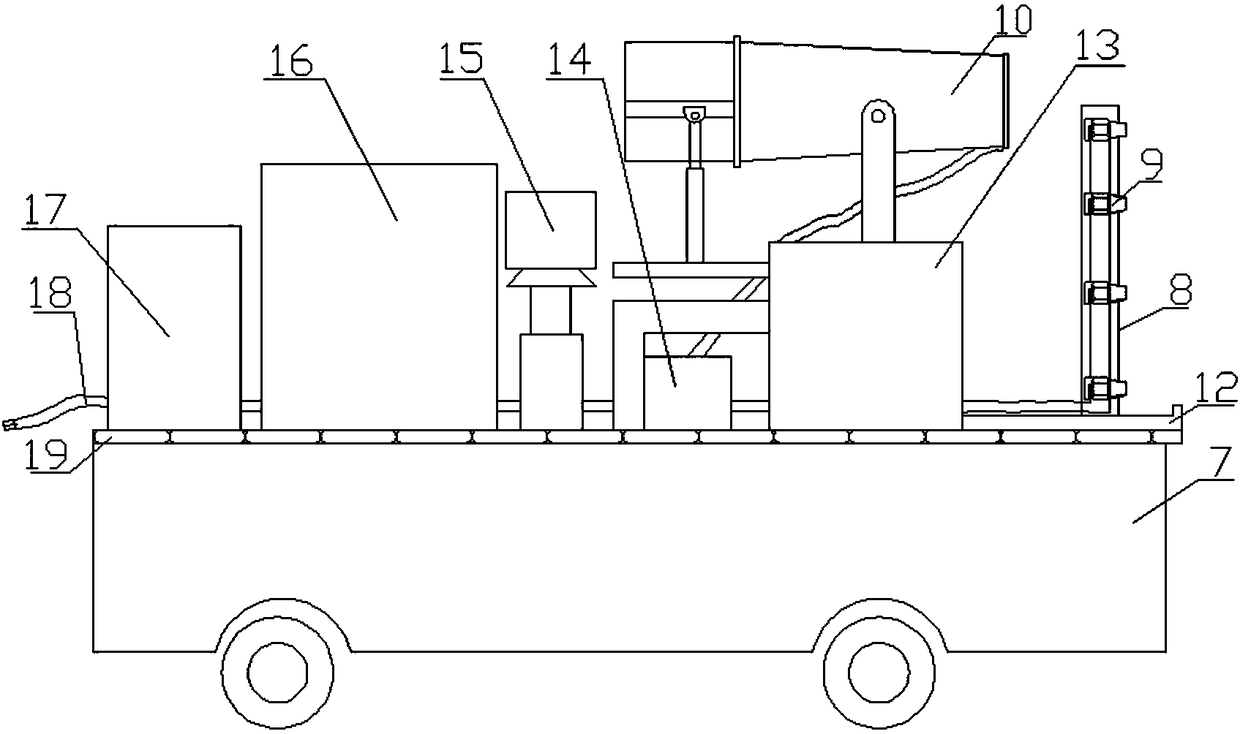

Method used

Image

Examples

Embodiment

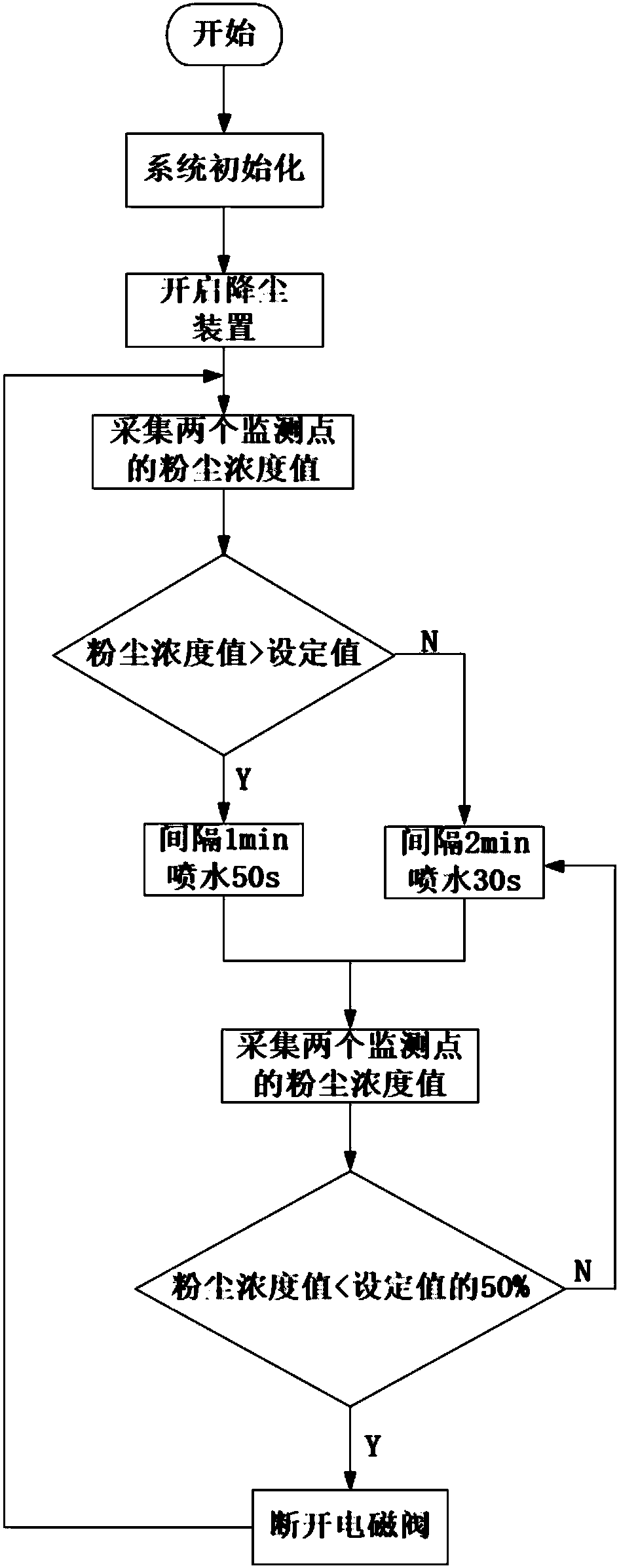

[0043] In the dust reduction process of this embodiment, the GCG1000 type dust concentration sensor feeds back the dust detection concentration synchronously to the electric control device 13, and the electric control device 13 compares the detection concentration with the dust concentration set value (6mg / m3), when the detection concentration When it is greater than the set value, control the dust suppression device to spray water for 50s every 1min. When the detected concentration is greater than 50% of the set value, control the dust suppression device to spray water for 30s every 2min. When the detected concentration is less than 50% of the set value, The electric control device 13 controls the solenoid valve 14 to automatically close. According to the difference in dust concentration near the tunnel face, the electric control device 13 can automatically adjust the dust reduction time of the second dust reduction device 8 and the air-driven dust reduction device 10 according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com