Integral measurement method and integral measurement device for magnetic field gradient of quadrupole magnet

A quadrupole magnet, integral measurement technology, applied in magnetic gradient measurement, magnetic field measurement using electromagnetic devices, magnetic field measurement using the principle of magnetic flux control, etc., to achieve the effect of avoiding angular errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

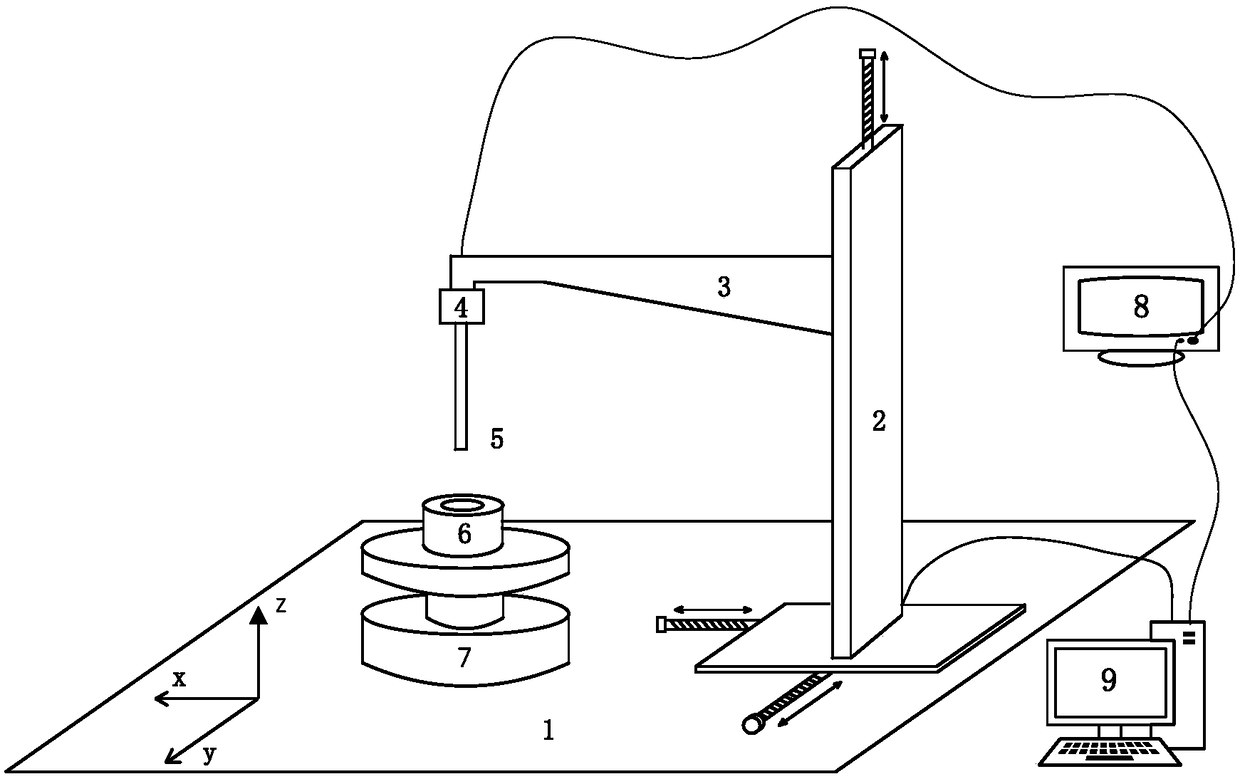

[0032] The present invention will be described in detail below by taking the integral measurement of the magnetic field gradient of a permanent magnet quadrupole magnet as an example in conjunction with the accompanying drawings.

[0033] The functions of each part of the quadrupole magnetic field gradient integral measuring device of the present invention are summarized as follows:

[0034] Optical platform 1: carrying measurement equipment;

[0035] Three-dimensional translation stage 2: drive the Hall plate 5 to move along the three directions of x, y, and z;

[0036] Measuring bracket 3: supporting the Hall plate 5 so that it moves together with the three-dimensional translation platform 2;

[0037] Universal adjustment device 4: can adjust the inclination angle (around the y-axis), the pitch angle (around the x-axis), and the roll angle (around the z-axis) of the Hall plate 5 respectively;

[0038] Hall plate 5: measure the magnetic induction intensity in the y directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com