Developing unit, treating box and electronic imaging device

A developing unit and developing roller technology, applied in the field of developing unit, processing box and electronic imaging device, can solve the capacity loss of the waste toner recovery bin in the developing chamber, reduce the production efficiency of the processing box, complex structures of the developing shell and the photosensitive shell, etc. problems, to achieve the effects of reduced occupation, good developing performance, and reduced capacity loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

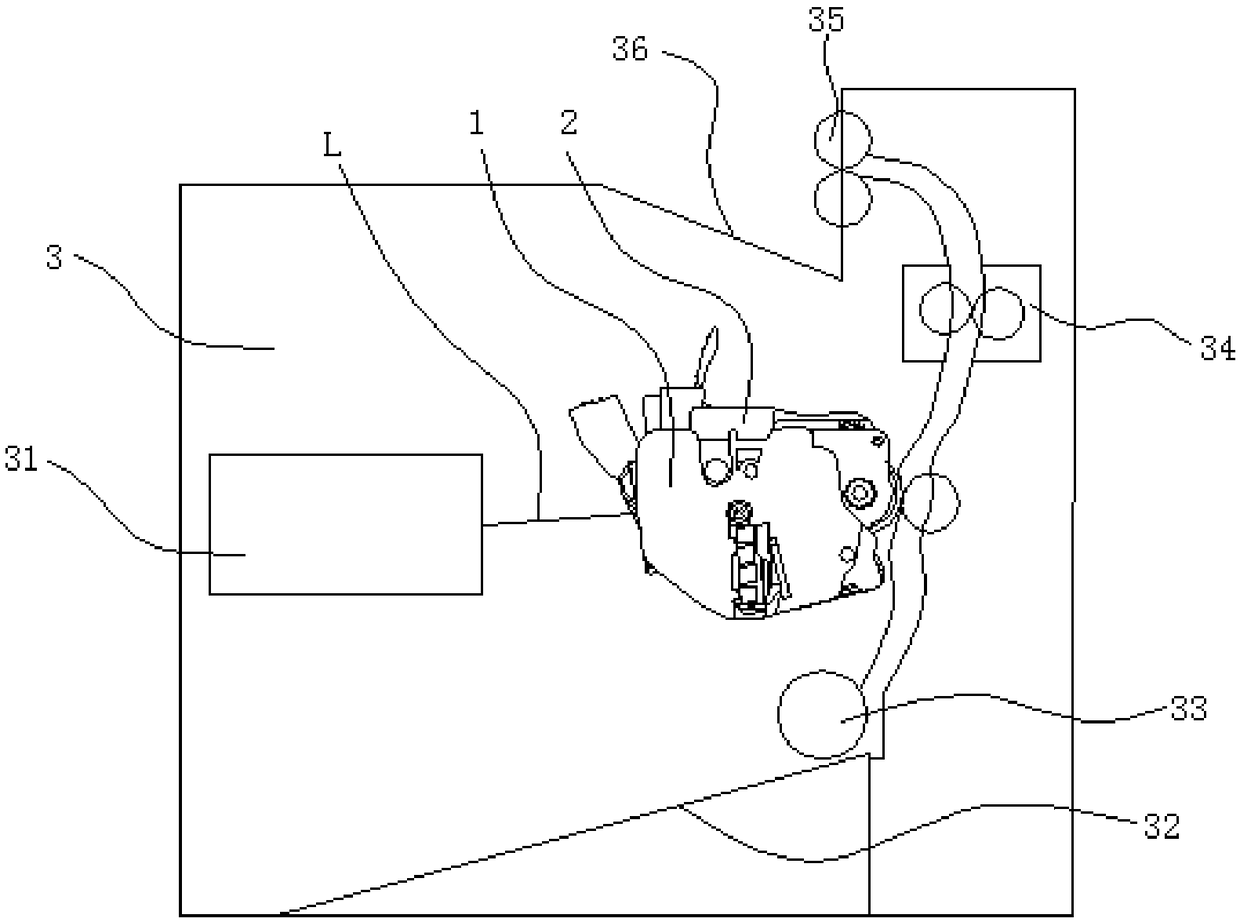

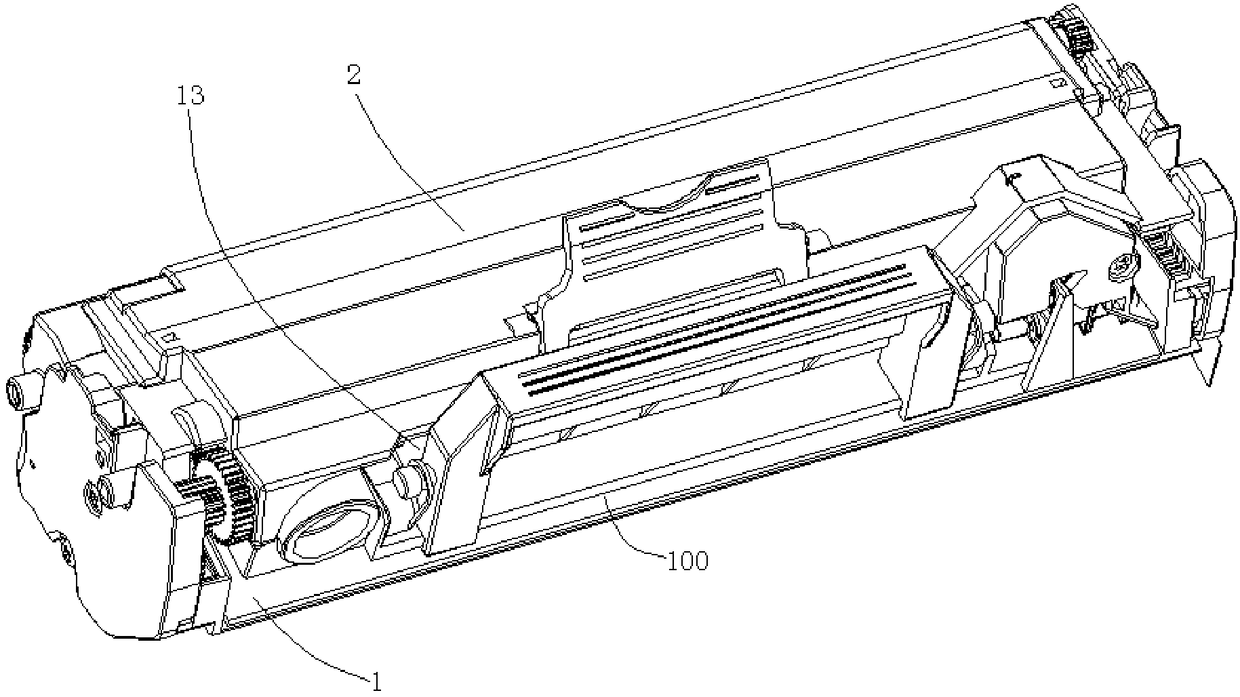

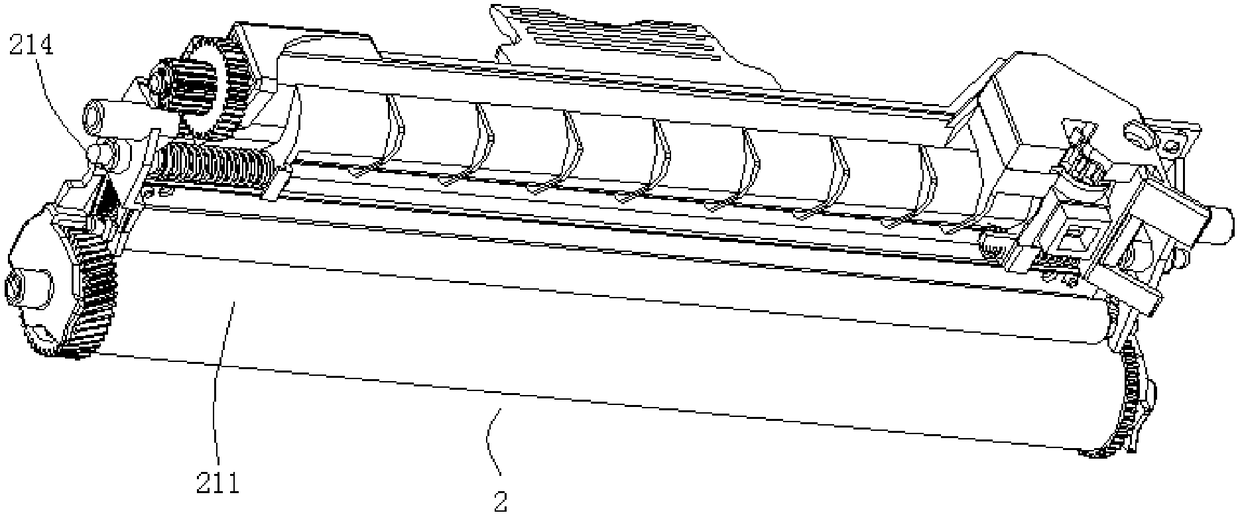

[0052] figure 2 It is a schematic structural diagram of a process cartridge including the developing unit provided in the first embodiment; image 3 It is a schematic structural diagram of the photosensitive unit assembled with the developing unit provided in the first embodiment; Figure 4 A schematic structural diagram of the developing unit provided in the first embodiment; Figure 5 for Figure 4 Put in a zoomed-in schematic.

[0053] Image 6 A cross-sectional view before the developing unit and the photosensitive unit provided in the first embodiment are not assembled in place; Figure 7 A cross-sectional view when the developing unit and the photosensitive unit provided in the first embodiment are assembled in place; Figure 8 This is a schematic diagram of the force between the abutting portion and the photosensitive unit in the developing unit provided in the first embodiment.

[0054] Figure 9 A schematic diagram of the installation of the forcing component ...

Embodiment 2

[0081] Figure 15 This is a schematic structural diagram of the developing unit and the photosensitive unit provided in the second embodiment.

[0082] Please refer to Figure 15 , this embodiment provides a developing unit 1. The difference between the developing unit 1 provided by this embodiment and the first embodiment is that in the developing unit 1 of this embodiment, the elastic member is a compression spring 1312, and the compression spring 1312 is arranged in the Below the support arm 1321 , the compression spring 1312 is specifically abutted between the lower surface of the support arm 1321 and the developing casing 11 .

[0083] Of course, the elastic member can also be an elastic protrusion extending downward from the bottom of the support arm 1321 , and the elastic protrusion also abuts against the developing casing 11 . In this embodiment, the developing unit 1 is described by taking the elastic member as the compression spring 1312 as an example.

[0084] Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com