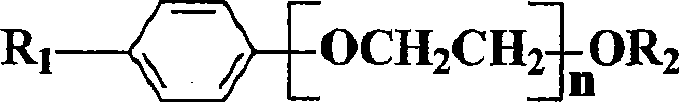

Neutral developer solution for positive light-sensitive polyimides photo resist

A technology of photosensitive polyimide photoresist and developer, which is applied in the field of materials to achieve the effects of good development performance, good dispersion stability and defoaming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

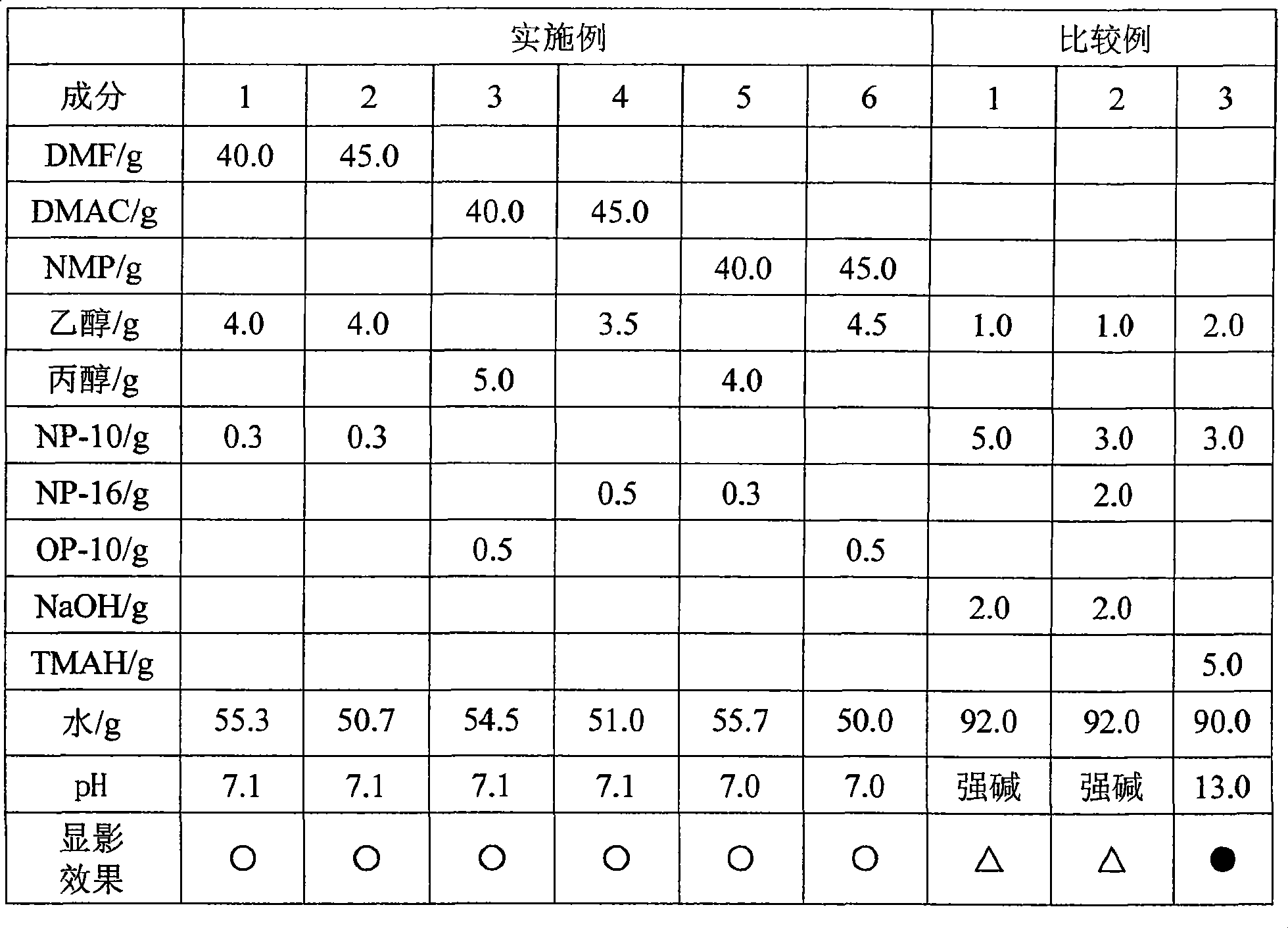

Embodiment 1

[0021] In a 250ml clean beaker, weigh 40.0g of N,N-dimethylformamide, 4.0g of absolute ethanol, 0.3g of nonylphenol polyoxyethylene ether (NP-10), and 55.7g of deionized water with pH=7.0 , and stir evenly to obtain the developer solution of the present invention, the pH value is about 7.1, and the developing effect is shown in Table 1.

Embodiment 2~6

[0023] The basic steps are the same as in Example 1, except that the composition and content are different. The specific composition, content and developing effect are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com