Surface acoustic wave non-contact atomization device

A surface acoustic wave, non-contact technology, applied in the field of electronic cigarettes, can solve problems affecting the atomization performance or service life of heating wires or vibrating plates, uneven particle size distribution of aerosols, high energy consumption and low efficiency of ultrasonic atomization, etc. , to achieve the effect of enhancing user experience, improving suction quality, and avoiding dry burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

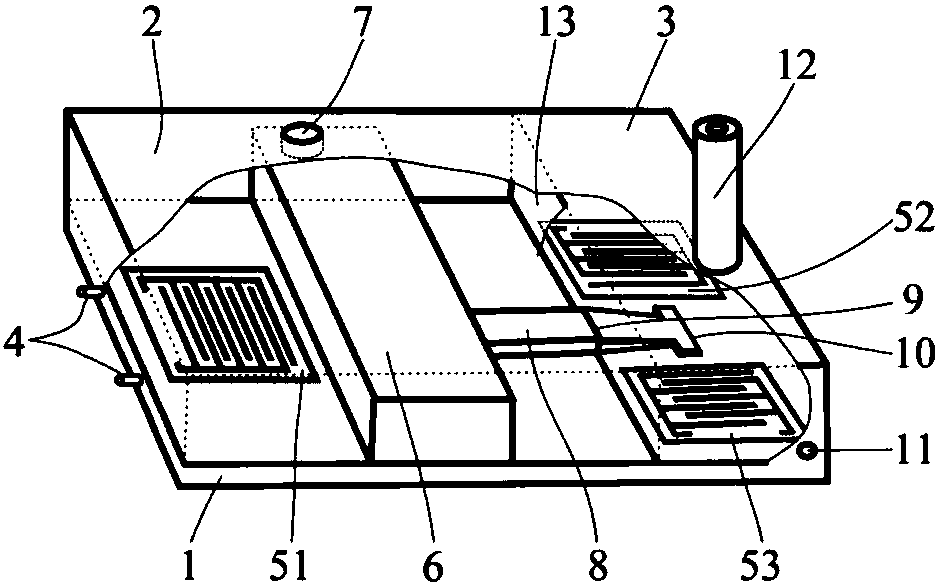

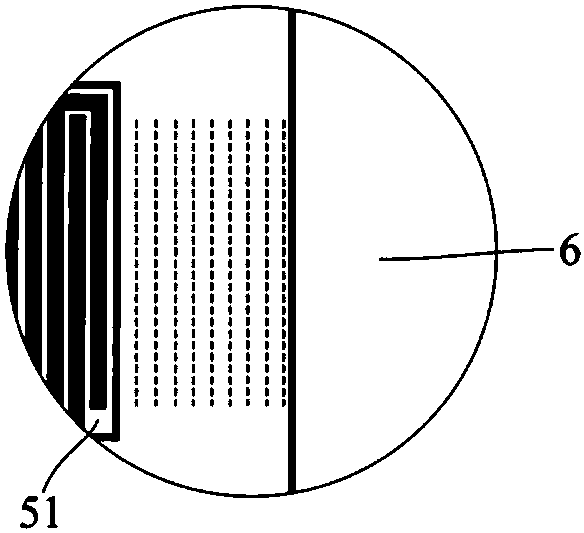

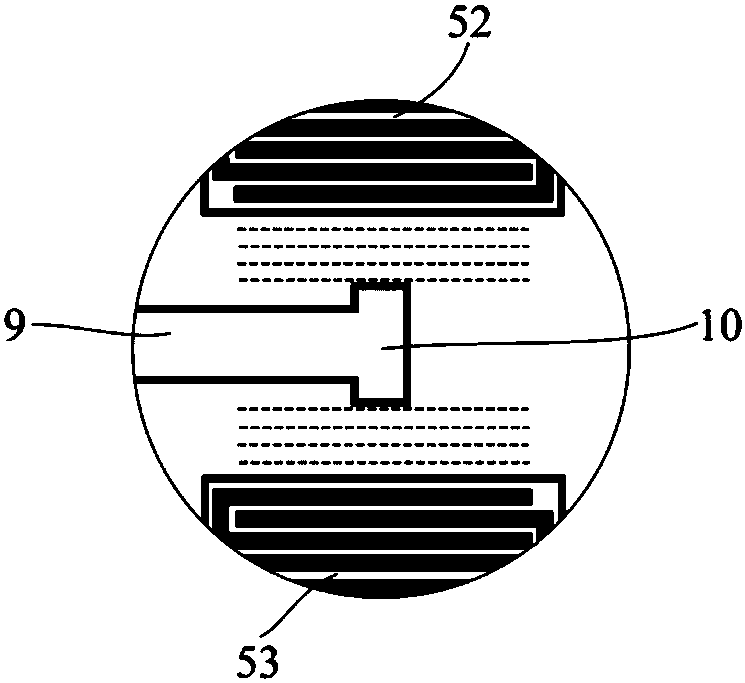

[0022] The schematic diagram of the structure of the surface acoustic wave electronic cigarette system according to the embodiment of the present invention is as follows: figure 1 As shown, the system includes a piezoelectric substrate 1 , a liquid guiding chamber 2 , an atomizing chamber 3 and a power feeding port 4 . The liquid guiding chamber 2 and the atomizing chamber 3 are arranged above the piezoelectric substrate 1 , and the two chambers are placed adjacent to each other, with an isolation plate 13 in between. The partially enlarged pictures of the liquid guide chamber and the atomization chamber are shown in figure 2 with image 3 . The feeding port 4 is arranged outside the piezoelectric substrate 1 and is externally connected to a hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com